CUSTO RESPONSI LITIES

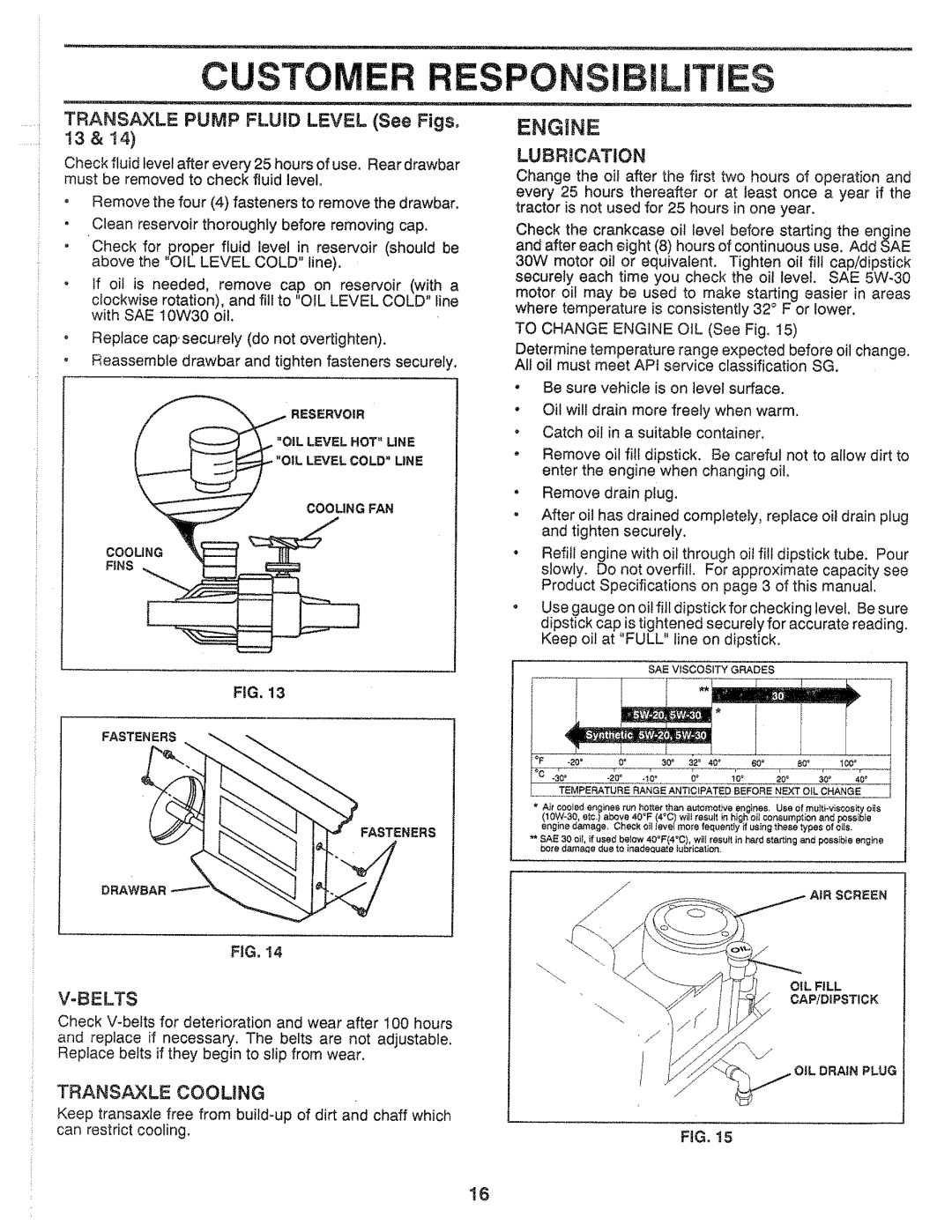

TRANSAXLE PUMP FLUUD LEVEL (See Figs, t3 & 14)

Check fluid level after every 25 hours of use, Rear drawbar must be removed to check fluid level°

+Remove the four (4) fasteners to remove the drawbar.

• Clean reservoir thoroughly before removing cap.

+Check for,proper fluid+ level in reservoir (should be above the OiL LEVEL COLD" line).

-If oil is needed, remove cap on reservoir (with a

clockwise rotation), and fill to "OIL LEVEL COLD" line with SAE 10W30 oil.

. Replace cap securely (do not overtighten).

•Reassemble drawbar and tighten fasteners securely.

ENGINE

LUBRMCATION

Change the oil after the first two hours of operation and every 25 hours thereafter or at least once a year if the tractor is not used for 25 hours in one year,

Check the crankcase oil level before starting the engine and after each eight (8) hours of continuous use. Add SAE 30W motor oil or equivalent. Tighten oil fi!t cap/dipstick securely each time you check the oil level, SAE

TO CHANGE ENGINE OIL (See Fig+ 15)

Determine temperature range expected before oil change. All oil must meet API service classification SG.

+Be sure vehicle is on level surface.

• Oil will drain more freely when warm.

, Catch oil in a suitable container.

+ Remove oil fill dipstick. Be careful not to allow dirt to enter the engine when changing oiL

+ Remove drain plug.

COOLING FAN

- After oil has drained completely, replace oil drain plug and tighten securely.

• Refill engine with oil through oil fill dipstick tube, Pour slowly. Do not overfil!. For approximate capacity see Product Specifications on page 3 of this manual,

" Use gauge on oi! fill dipstick for checking level. Be sure dipstick cap is tightened securely for accurate reading. Keep oil at "FULL" fine on dipstick.

SAE VISCOSITY GRADES

FIG. 13

FASTENERS "_,

°F +20° 0+ 30 ° 32 _ 40 ° 60= 80+ 100=

.+,o° +4° +° ,'o+ _° +,o° +,o°

TEMPERATURE RANGE ANTICIPATED BEFORF NF+XT OIL CHANGE

A+r coofed engines run hotter than e_omet}ve sng+nss< Use ef m t_lti*v_scos;ty o++s

FASTENERS

engine damage. Check oil feve_more fequent+y if using these types of oils.

** SAE 30 <_+I,if use_ be_c_, 40°F(4°0) witt result in I'_,td starting and pessib_e engine _ore _am&qe _Je to naaeQuate lubrication,

DRAWBAR

AIR SCREEN

FIG, 14

|

| OIL FILL |

+ | CAP/DIPSTICK |

Check

and replace if necessary. The belts are not adjustable, Replace belts if they begin to slip from wear.

TRANSAXLE COOUNG

Keep transaxfe free from

/ | OIL DRAIN PLUG |

|

FiG, 15

16