FramePro®601

Clipped Head Framing/Sheathing Nailer

Fastening Solutions™

Best Value in the Industry!

Clipped head nailers provide all the important features you want at an affordable price. These compact framers are easy to handle, and easy on the arm. Their 30˚ short,

Applications:

Framing, truss building, subflooring, sheathing, decking, siding, fencing, pallets and crate assembly

.Features and Benefits:

•Sawtooth safety that digs in for precision toenailing

•Shorter,

•Drives ring and smooth shank nails in four gauges (.113

•Reliable internal design with full round driver

•Adjustable exhaust

•Lightweight and powerful

•Adjustable

•Soft comfort grip handle reduces fatigue

•

Tool Specifications:

| FramePro 601 |

Power: | 884 in/lbs |

Tool Weight: | 8 lbs (3.6 kg) |

Height: | 13 .5" (343 mm) |

Length: | 14.8" (376 mm) |

Nail Capacity: | 65 |

Reg. Operating Pressure:

Mode of Operation: Available with either Dual Action or Restrictive Trigger activating mechanisms.

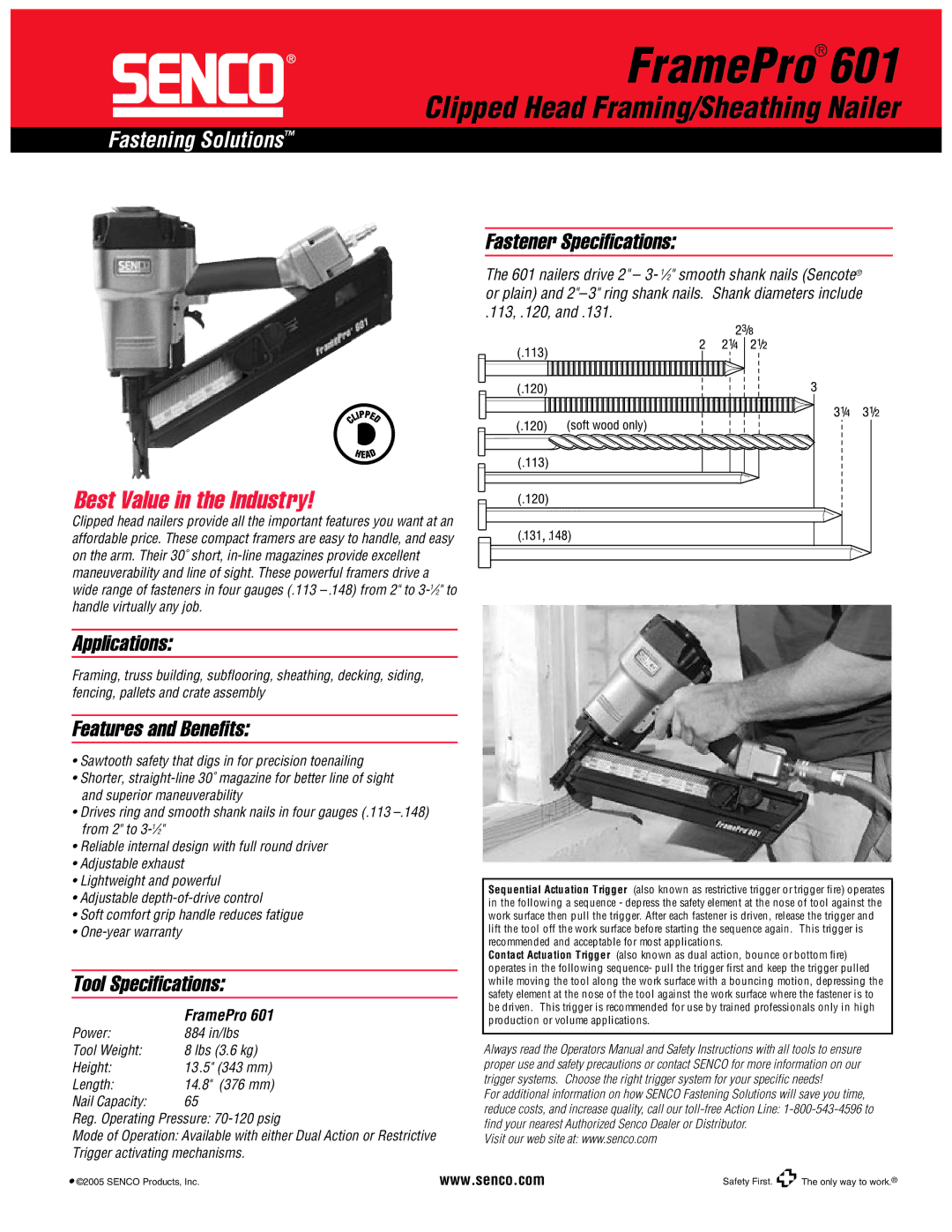

Fastener Specifications:

The 601 nailers drive 2" – 3- 1⁄2" smooth shank nails (Sencote® or plain) and 2"– 3" ring shank nails. Shank diameters include

.113, .120, and .131.

Sequential Actuation Trigger (also known as restrictive trigger or trigger fire) operates in the following a sequence - depress the safety element at the nose of tool against the work surface then pull the trigger. After each fastener is driven, release the trigger and lift the tool off the work surface before starting the sequence again. This trigger is recommended and acceptable for most applications.

Contact Actuation Trigger (also known as dual action, bounce or bottom fire)

operates in the following sequence- pull the trigger first and keep the trigger pulled while moving the tool along the work surface with a bouncing motion, depressing the safety element at the nose of the tool against the work surface where the fastener is to be driven. This trigger is recommended for use by trained professionals only in high production or volume applications.

Always read the Operators Manual and Safety Instructions with all tools to ensure proper use and safety precautions or contact SENCO for more information on our trigger systems. Choose the right trigger system for your specific needs!

For additional information on how SENCO Fastening Solutions will save you time, reduce costs, and increase quality, call our

Visit our web site at: www.senco.com

• ©2005 SENCO Products, Inc. | www.senco.com | Safety First. | The only way to work.® |