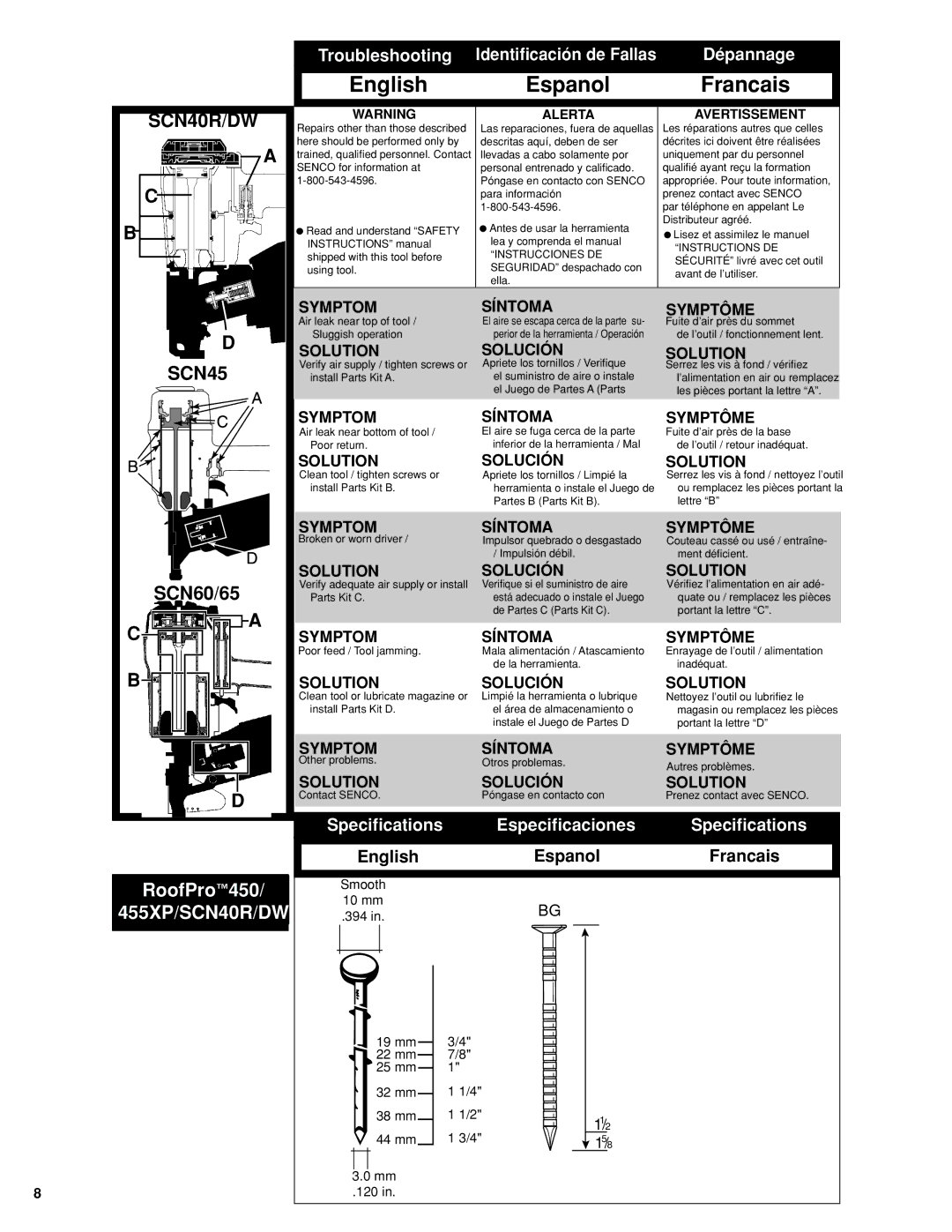

SCN45, SCN65, SCN60, SCN56 specifications

The Senco SCN series of nailers represents a significant advancement in the world of pneumatic fastening tools, designed to meet the diverse needs of professionals and DIY enthusiasts alike. The line primarily includes the SCN60, SCN65, SCN45, and SCN56, each offering unique features while sharing core technologies and characteristics that guarantee efficiency and reliability.The SCN60 is a versatile 20-gauge nailer that excels in precision and performance. It is known for its lightweight design, making it easy to maneuver in tight spaces. The SCN60 utilizes a tool-free depth adjustment feature, allowing users to set the desired nail depth without additional tools. This nailer is particularly effective for delicate trim and molding work, ensuring that finishes remain intact and undamaged.

On the other hand, the SCN65 offers a more robust solution for heavier-duty applications. This 16-gauge nailer is built to drive larger fasteners securely, providing exceptional holding power. Equipped with an adjustable exhaust, the SCN65 directs air away from the user, enhancing comfort during prolonged use. Its anti-dry fire mechanism prevents the tool from firing when no nails are present, which prolongs the tool's life and minimizes wasted fasteners.

The SCN45 is a 21-degree framing nailer designed for larger construction projects. It combines power and speed, capable of firing full head nails with precision. The SCN45 features a high-capacity canister that reduces reloading time, allowing users to work more efficiently. Its lightweight design helps reduce user fatigue, making it suitable for extended use on job sites.

Completing the lineup, the SCN56 is a compact pneumatic nailer intended for finish and cabinetry applications. With its ergonomic design, it is exceptionally comfortable to use, even in long sessions. The SCN56 also boasts a selective actuation feature, allowing users to switch between single and contact firing modes easily. This versatility is particularly beneficial in various applications, providing users with the flexibility they need.

Collectively, the Senco SCN series nailers prioritize user experience, reliability, and efficiency. They are built with durable materials and incorporate advanced technologies that minimize maintenance needs. Whether for framing, trim work, or cabinetry projects, these tools are designed to deliver precision and power, making them indispensable in any professional’s toolkit.