PWS-70115, PWS-77120, PWS-42115, PWS-70120, PWS-77115 specifications

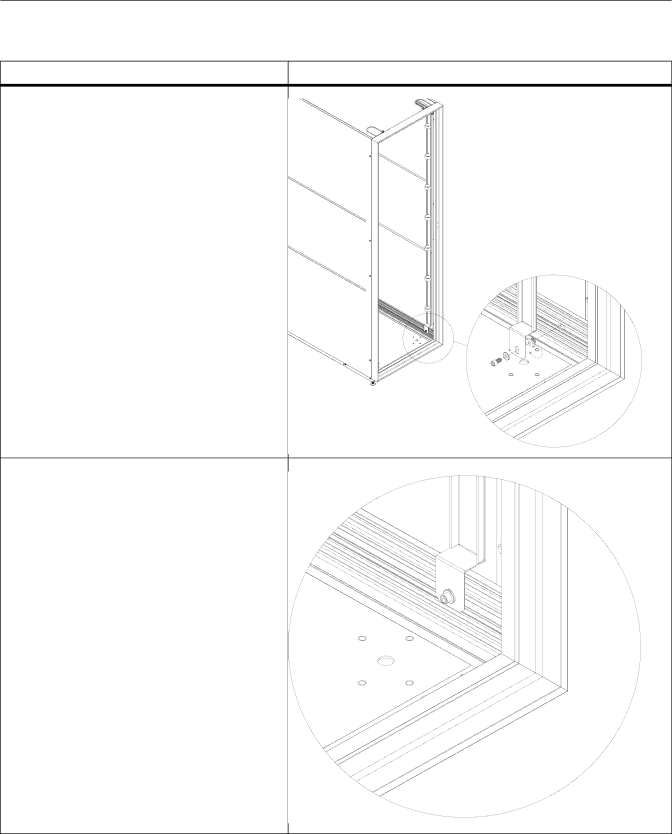

SharkRack has carved a niche in the realm of IT infrastructure with its impressive lineup of server racks designed for both functionality and style. Among these, the PWS-42115, PWS-70115, PWS-77120, PWS-70120, and PWS-77115 models stand out, each tailored to meet diverse requirements in data centers and enterprise environments.The SharkRack PWS-42115 model is designed with a robust steel frame that ensures durability while maintaining a sleek profile. With a height of 42U, it provides ample space for equipment, along with passive cooling and cable management solutions. It features adjustable rails to accommodate various server sizes, ensuring flexibility for IT setups in dynamic environments.

Moving to the PWS-70115, it is optimized for larger hardware setups with 70U of height. This high-density rack offers greater airflow management and includes a mesh front door for optimal ventilation. Its deep design supports larger servers and equipment, making it ideal for organizations anticipating growth or requiring extensive storage capacity.

The PWS-77120 and PWS-70120 add another layer of versatility. The PWS-77120 boasts a 77U height while maintaining a 1200mm depth, facilitating maximum rack space without compromising on airflow. Furthermore, its innovative design includes removable side panels, allowing for easy access during maintenance operations. The PWS-70120, on the other hand, is a fraction shorter at 70U but still offers similar depth for accommodating extra-large installations.

Lastly, the PWS-77115 is a fantastic option for those who need a combination of height and ease of access. Standing at 77U with a width that allows for significant variety in mounting hardware, this model is perfect for businesses that are scaling up their operations and require accessibility for frequent equipment changes.

All models come equipped with integrated cable management systems, ensuring neat and organized layouts that enhance airflow and reduce overheating. Additionally, they provide compatibility with various power distribution units to streamline energy use.

In conclusion, the PWS-42115, PWS-70115, PWS-77120, PWS-70120, and PWS-77115 by SharkRack represent cutting-edge technology and robust design that cater to the evolving needs of modern data centers. Their combination of height, depth, and configurable features makes them indispensable for any business looking to optimize its IT infrastructure.