Maintenance (continued)

10 - hour maintenance

(more frequently in dusty conditions)

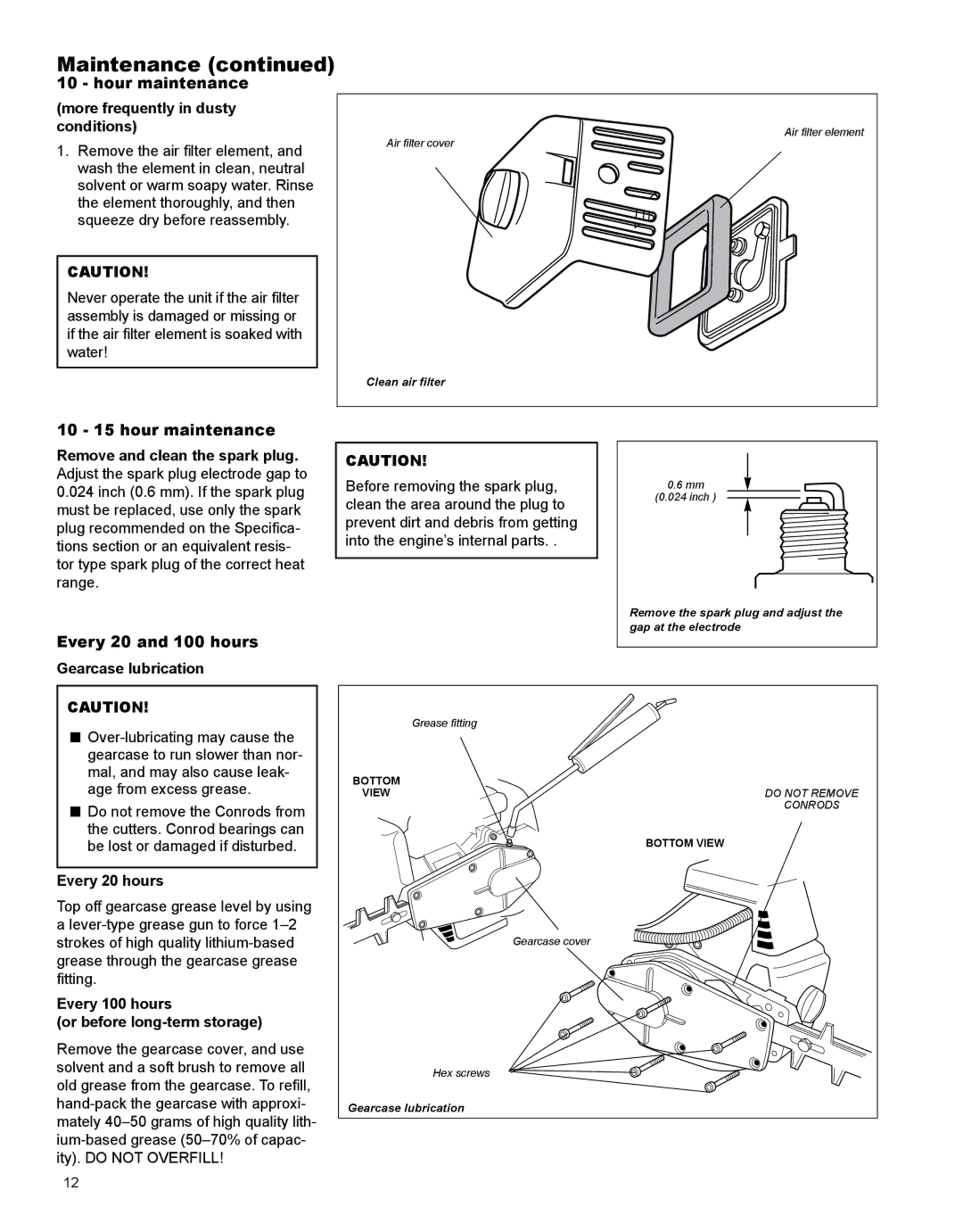

1.Remove the air filter element, and wash the element in clean, neutral solvent or warm soapy water. Rinse the element thoroughly, and then squeeze dry before reassembly.

CAUTION!

Never operate the unit if the air filter

assembly is damaged or missing or

if the air filter element is soaked with

water!

10 - 15 hour maintenance

Remove and clean the spark plug.

Adjust the spark plug electrode gap to 0.024 inch (0.6 mm). If the spark plug must be replaced, use only the spark

plug recommended on the Specifica-

tions section or an equivalent resis- tor type spark plug of the correct heat range.

Every 20 and 100 hours

Gearcase lubrication

Air filter element

Air filter cover

Clean air filter

CAUTION! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

Before removing the spark plug, |

|

| 0.6 mm |

|

|

|

|

| |||

|

|

|

|

|

| ||||||

clean the area around the plug to |

|

| (0.024 inch ) |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| |

prevent dirt and debris from getting |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

into the engine’s internal parts. . |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

| Remove the spark plug and adjust the |

|

| ||||||

|

|

| gap at the electrode |

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

CAUTION!

■■Do not remove the Conrods from the cutters. Conrod bearings can be lost or damaged if disturbed.

Every 20 hours

Top off gearcase grease level by using a

fitting.

Every 100 hours

(or before long-term storage)

Remove the gearcase cover, and use solvent and a soft brush to remove all old grease from the gearcase. To refill,

Grease fitting |

|

BOTTOM |

|

VIEW | DO NOT REMOVE |

| CONRODS |

| BOTTOM VIEW |

| Gearcase cover |

Hex screws |

|

Gearcase lubrication |

|

12