Maintenance

Cleaning the Sprayer

WARNING!

Always relieve pressure from the sprayer tank by pulling the pressure relief valve before removing the tank lid.

After finishing the spray application, empty the sprayer and wash all equipment in an approved decontamination area.

®

WARNING!

Remove all chemicals and wash before storing the sprayer. Chemical products have different reactions and can cause damage to the sprayer components and the environment. Unidentified chemicals left in the sprayer tank can pose a serious health threat to anyone servicing the unit and unaware of its presence!

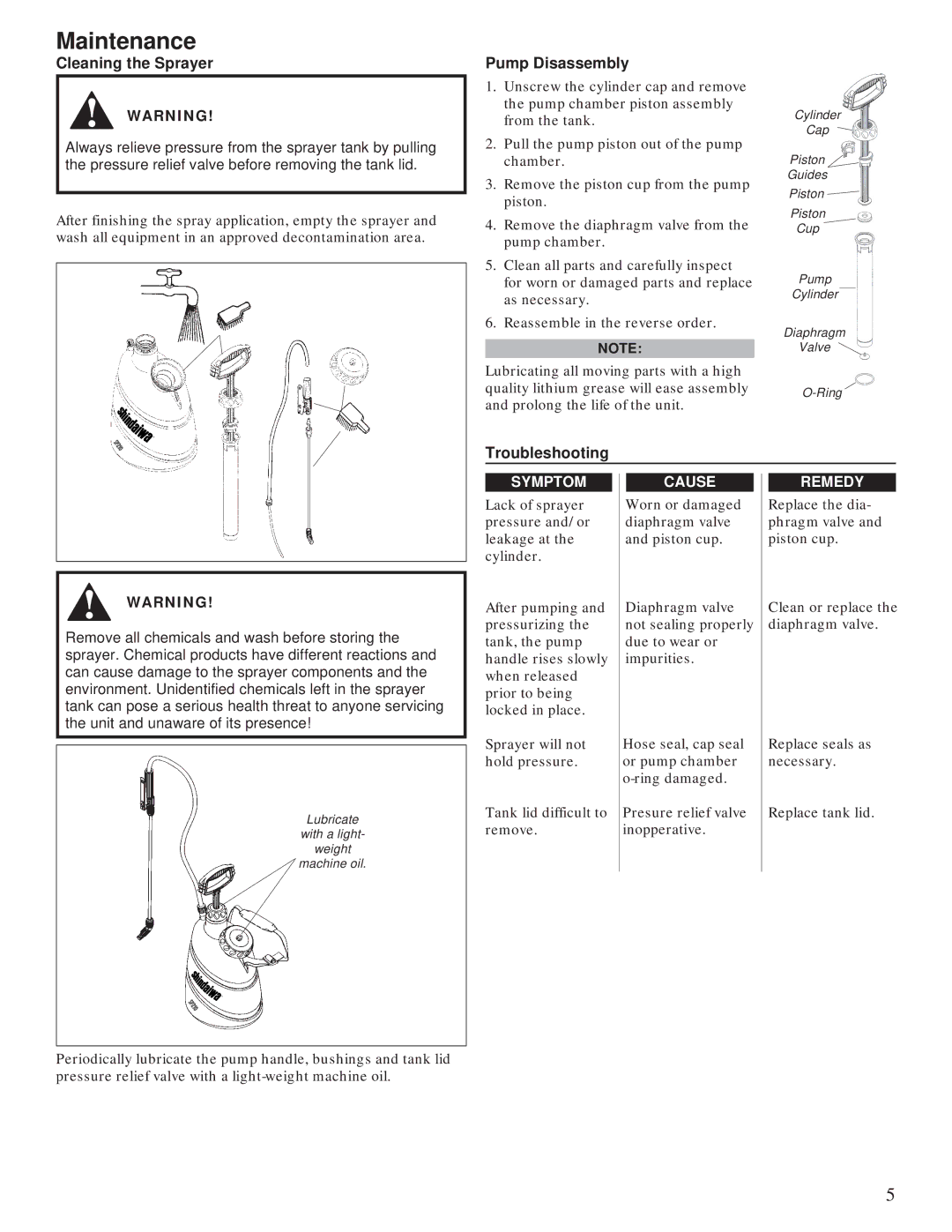

Lubricate

with a light-

weight

machine oil.

®

Periodically lubricate the pump handle, bushings and tank lid pressure relief valve with a

Pump Disassembly

1. Unscrew the cylinder cap and remove |

|

|

|

| |||||

the pump chamber piston assembly |

|

| Cylinder | ||||||

from the tank. |

|

|

|

|

|

| |||

2. Pull the pump piston out of the pump |

|

| Cap | ||||||

|

|

|

| ||||||

chamber. |

|

|

|

|

|

| Piston | ||

3. Remove the piston cup from the pump |

|

| Guides | ||||||

|

| Piston | |||||||

piston. |

|

|

|

|

|

| |||

|

|

|

|

|

| Piston | |||

4. Remove the diaphragm valve from the |

|

| |||||||

|

| Cup | |||||||

pump chamber. |

|

|

|

|

|

|

|

| |

5. Clean all parts and carefully inspect |

|

| Pump | ||||||

for worn or damaged parts and replace |

|

| |||||||

as necessary. |

|

|

|

|

|

| Cylinder | ||

6. Reassemble in the reverse order. |

|

| Diaphragm | ||||||

|

|

|

|

|

|

| |||

NOTE: |

|

| Valve | ||||||

Lubricating all moving parts with a high |

|

|

|

| |||||

quality lithium grease will ease assembly |

|

| |||||||

and prolong the life of the unit. |

|

|

|

| |||||

Troubleshooting |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| |

SYMPTOM | CAUSE | REMEDY | |||||||

|

|

|

|

|

| ||||

Lack of sprayer |

| Worn or damaged |

|

| Replace the dia- | ||||

pressure and/or |

| diaphragm valve |

|

| phragm valve and | ||||

leakage at the |

| and piston cup. |

|

| piston cup. | ||||

cylinder. |

|

|

|

|

|

|

|

| |

After pumping and |

| Diaphragm valve |

|

| Clean or replace the | ||||

pressurizing the |

| not sealing properly |

|

| diaphragm valve. | ||||

tank, the pump |

| due to wear or |

|

|

|

| |||

handle rises slowly |

| impurities. |

|

|

|

| |||

when released |

|

|

|

|

|

|

|

| |

prior to being |

|

|

|

|

|

|

|

| |

locked in place. |

|

|

|

|

|

|

|

| |

Sprayer will not |

| Hose seal, cap seal |

|

| Replace seals as | ||||

hold pressure. |

| or pump chamber |

|

| necessary. | ||||

|

|

|

|

|

| ||||

Tank lid difficult to |

| Presure relief valve |

|

| Replace tank lid. | ||||

remove. |

| inopperative. |

|

|

|

| |||

|

|

|

|

|

|

|

|

| |

5