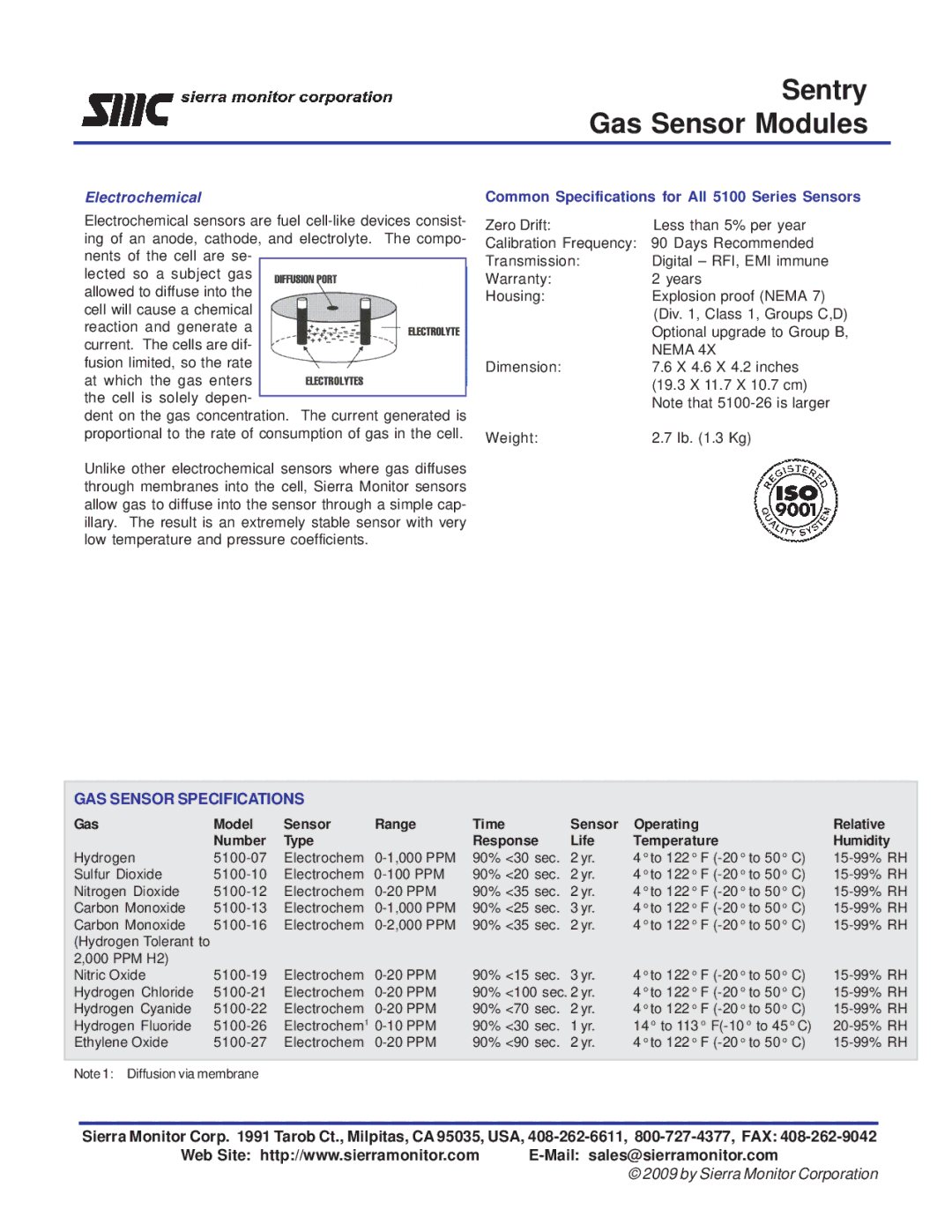

5100 Series specifications

Sierra Monitor Corporation, a leader in industrial communication solutions, offers the 5100 Series, designed for robust monitoring and control of gas sensors and alarms. The 5100 Series is particularly suited for industrial settings, ensuring safety and compliance with environmental regulations.One of the notable features of the 5100 Series is its advanced networking capabilities. It supports various communication protocols, such as Modbus, TCP/IP, and other industrial standards, allowing seamless integration with existing control systems. This flexibility ensures that users can easily connect the monitors to their infrastructure, facilitating real-time data access and control.

The 5100 Series is equipped with a powerful microprocessor that enables enhanced data processing and storage capabilities. Users can benefit from features like data logging, which records critical safety and performance information for analysis and reporting. This is particularly useful in situations where regulatory compliance is necessary, as it provides a historical record of gas levels and system performance.

Another key characteristic of the Sierra Monitor 5100 Series is its user-friendly interface. The device features an intuitive LCD display that shows real-time data, visual alerts, and system diagnostics. This ensures that operators can quickly assess the status of gas levels and respond promptly to any alerts or anomalies. The system also supports remote monitoring, allowing users to access data via web browsers or dedicated applications.

The 5100 Series utilizes innovative sensor technology to detect a variety of gases including methane, propane, hydrogen sulfide, and carbon dioxide. These sensors offer high sensitivity and accuracy, ensuring reliable detection even in challenging environments. Furthermore, the sensors are designed to be resistant to contamination, which is critical in industrial settings where exposure to dust and other particulates is common.

Built to endure harsh conditions, the 5100 Series features rugged construction and IP-rated enclosures, ensuring reliability and durability over time. This is essential for maintaining safety standards in environments that may experience extreme temperatures, humidity, or pressure changes.

In conclusion, the Sierra Monitor Corporation 5100 Series is an exemplary solution for gas detection and monitoring in industrial applications. With its advanced networking capabilities, data logging features, user-friendly interface, and durable design, it provides an efficient and effective means of ensuring safety and compliance in the workplace.