Sentry Printer

KEY EVENT REPORT

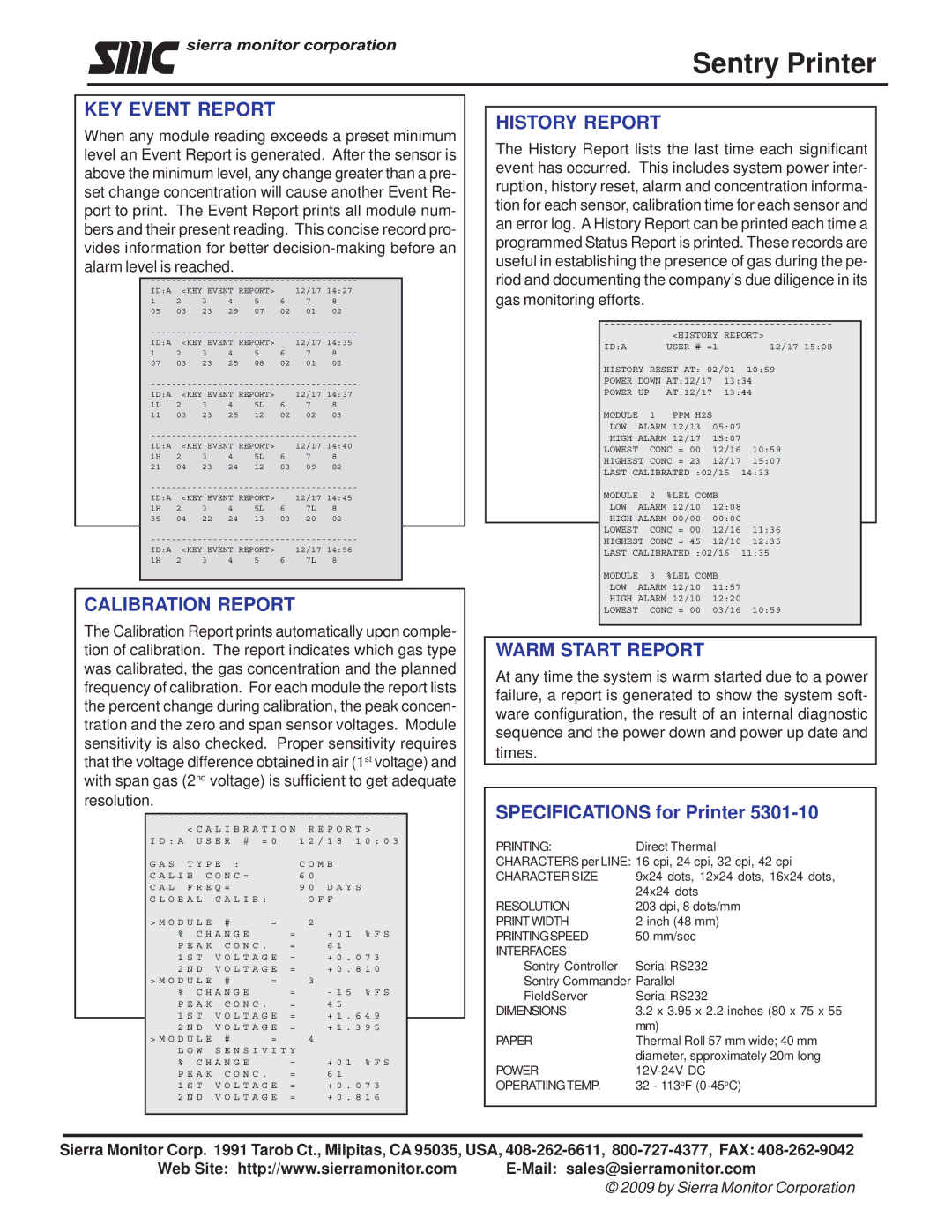

When any module reading exceeds a preset minimum level an Event Report is generated. After the sensor is above the minimum level, any change greater than a pre- set change concentration will cause another Event Re- port to print. The Event Report prints all module num- bers and their present reading. This concise record pro- vides information for better

ID:A | <KEY EVENT | REPORT> |

| 12/17 14:27 | |||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

05 | 03 | 23 | 29 | 07 | 02 | 01 | 02 |

ID:A | <KEY EVENT | REPORT> |

| 12/17 14:35 | |||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

07 | 03 | 23 | 25 | 08 | 02 | 01 | 02 |

ID:A | <KEY EVENT | REPORT> |

| 12/17 14:37 | |||

1L | 2 | 3 | 4 | 5L | 6 | 7 | 8 |

11 | 03 | 23 | 25 | 12 | 02 | 02 | 03 |

ID:A | <KEY EVENT | REPORT> |

| 12/17 14:40 | |||

1H | 2 | 3 | 4 | 5L | 6 | 7 | 8 |

21 | 04 | 23 | 24 | 12 | 03 | 09 | 02 |

ID:A | <KEY EVENT | REPORT> |

| 12/17 14:45 | |||

1H | 2 | 3 | 4 | 5L | 6 | 7L | 8 |

35 | 04 | 22 | 24 | 13 | 03 | 20 | 02 |

ID:A |

| <KEY EVENT | REPORT> |

| 12/17 14:56 | ||

1H | 2 | 3 | 4 | 5 | 6 | 7L | 8 |

CALIBRATION REPORT

The Calibration Report prints automatically upon comple- tion of calibration. The report indicates which gas type was calibrated, the gas concentration and the planned frequency of calibration. For each module the report lists the percent change during calibration, the peak concen- tration and the zero and span sensor voltages. Module sensitivity is also checked. Proper sensitivity requires that the voltage difference obtained in air (1st voltage) and with span gas (2nd voltage) is sufficient to get adequate resolution.

| - - - - - - - - - - - - - - - - - - - - - - - - - - - - |

|

| |||||||

|

| < C A L I B R A T I O N | R E P O R T > |

|

| |||||

| I D : A | U S E R | # = 0 | 1 2 / 1 8 1 0 : 0 3 |

|

| ||||

| G A S T Y P E : |

|

| C O M B |

|

| ||||

| C A L I B C O N C = |

| 6 0 |

|

|

| ||||

| C A L F R E Q = |

|

| 9 0 | D A Y S |

|

| |||

| G L O B A L | C A L I B : |

| O F F |

|

| ||||

| > M O D U L | E | # |

| = | 2 |

|

|

| |

| % | C H A N G E | = |

| + 0 1 % F S |

|

| |||

| P E A K | C O N C . | = |

| 6 1 |

|

| |||

| 1 S T V O L T A G E = |

| + 0 . 0 7 3 |

|

| |||||

| 2 N D | V O L T A G E = |

| + 0 . 8 1 0 |

|

| ||||

| > M O D U L | E | # |

| = | 3 |

|

|

| |

| % | C H A N G E | = |

| - 1 5 % F S |

|

| |||

| P E A K | C O N C . | = |

| 4 5 |

|

| |||

| 1 S T | V O L T A G E = |

| + 1 . 6 4 9 |

|

| ||||

| 2 N D | V O L T A G E = |

| + 1 . 3 9 5 |

|

| ||||

| > M O D U L | E | # |

| = | 4 |

|

|

| |

| L O W | S E N S I V I T Y |

|

|

|

| ||||

| % C H A N G E | = |

| + 0 1 % F S |

|

| ||||

| P E A K C O N C . | = |

| 6 1 |

|

| ||||

| 1 S T | V O L T A G E = |

| + 0 . 0 7 3 |

|

| ||||

| 2 N D | V O L T A G E = |

| + 0 . 8 1 6 |

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

HISTORY REPORT

The History Report lists the last time each significant event has occurred. This includes system power inter- ruption, history reset, alarm and concentration informa- tion for each sensor, calibration time for each sensor and an error log. A History Report can be printed each time a programmed Status Report is printed. These records are useful in establishing the presence of gas during the pe- riod and documenting the company’s due diligence in its gas monitoring efforts.

|

| <HISTORY | REPORT> | |

ID:A |

| USER # =1 | 12/17 15:08 | |

HISTORY RESET AT: 02/01 10:59 | ||||

POWER | DOWN AT:12/17 |

| 13:34 | |

POWER | UP | AT:12/17 |

| 13:44 |

MODULE | 1 | PPM H2S |

|

|

LOW | ALARM | 12/13 | 05:07 | |

HIGH | ALARM | 12/17 | 15:07 | |

LOWEST | CONC = 00 | 12/16 | 10:59 | |

HIGHEST CONC = 23 | 12/17 | 15:07 | ||

LAST CALIBRATED :02/15 | 14:33 | |||

MODULE | 2 | %LEL COMB |

| |

LOW | ALARM 12/10 | 12:08 |

| |

HIGH ALARM 00/00 | 00:00 |

| ||

LOWEST | CONC = 00 | 12/16 | 11:36 | |

HIGHEST CONC = 45 | 12/10 | 12:35 | ||

LAST CALIBRATED :02/16 | 11:35 | |||

MODULE | 3 | %LEL COMB |

| |

LOW | ALARM 12/10 | 11:57 |

| |

HIGH ALARM 12/10 | 12:20 |

| ||

LOWEST | CONC = 00 | 03/16 | 10:59 | |

WARM START REPORT

At any time the system is warm started due to a power failure, a report is generated to show the system soft- ware configuration, the result of an internal diagnostic sequence and the power down and power up date and times.

SPECIFICATIONS for Printer 5301-10

PRINTING: | Direct Thermal |

CHARACTERS per LINE: 16 cpi, 24 cpi, 32 cpi, 42 cpi | |

CHARACTER SIZE | 9x24 dots, 12x24 dots, 16x24 dots, |

| 24x24 dots |

RESOLUTION | 203 dpi, 8 dots/mm |

PRINTWIDTH | |

PRINTINGSPEED | 50 mm/sec |

INTERFACES |

|

Sentry Controller | Serial RS232 |

Sentry Commander Parallel | |

FieldServer | Serial RS232 |

DIMENSIONS | 3.2 x 3.95 x 2.2 inches (80 x 75 x 55 |

| mm) |

PAPER | Thermal Roll 57 mm wide; 40 mm |

| diameter, spproximately 20m long |

POWER | |

OPERATIINGTEMP. | 32 - 113oF |

Sierra Monitor Corp. 1991 Tarob Ct., Milpitas, CA 95035, USA,

Web Site: http://www.sierramonitor.com | |

| © 2009 by Sierra Monitor Corporation |