Knowing the protocol

When a specification states that

aproduct has an

Likewise, when a specification states that a product has an Ethernet port, it only defines the form of the hardware interface, commonly known as a

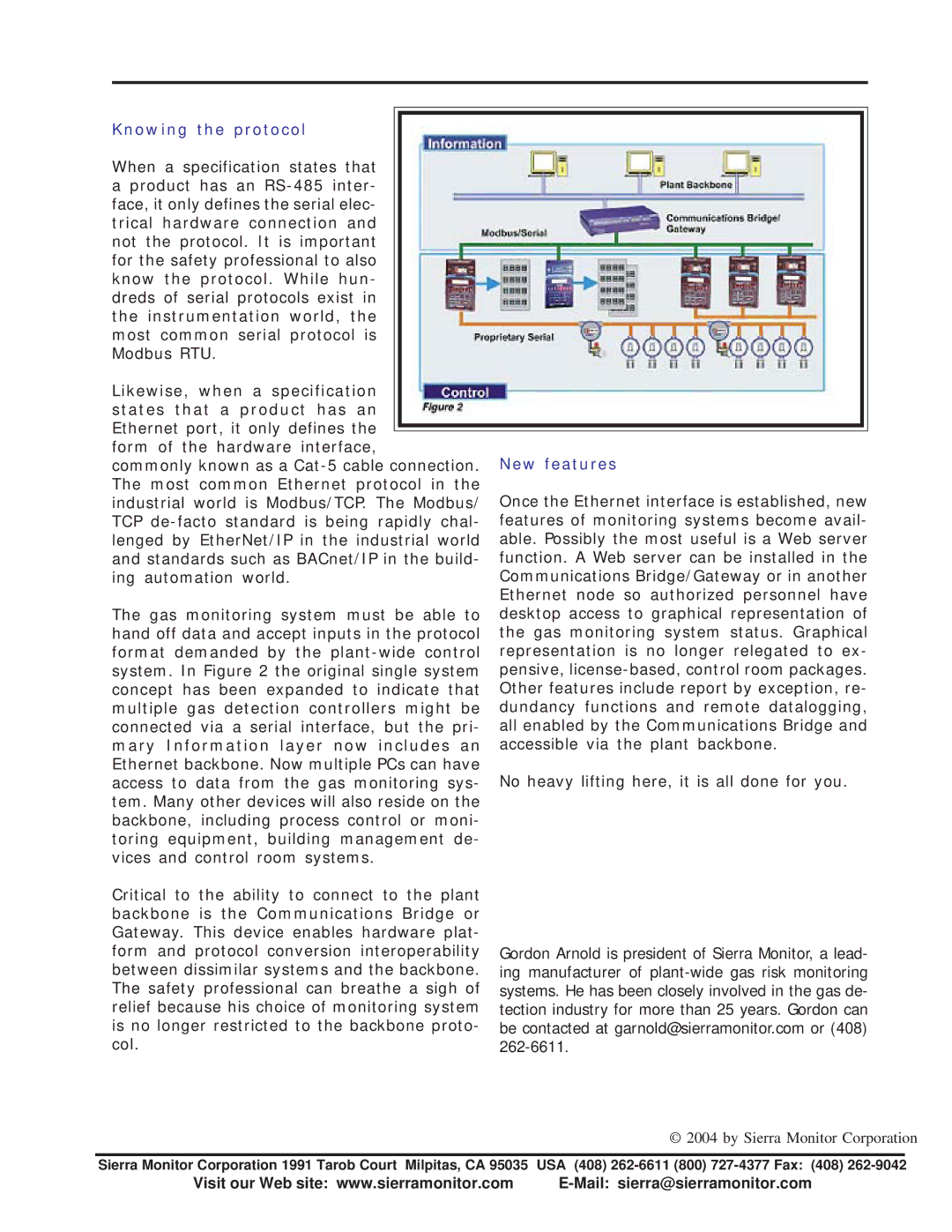

The gas monitoring system must be able to hand off data and accept inputs in the protocol format demanded by the

Critical to the ability to connect to the plant backbone is the Communications Bridge or Gateway. This device enables hardware plat- form and protocol conversion interoperability between dissimilar systems and the backbone. The safety professional can breathe a sigh of relief because his choice of monitoring system is no longer restricted to the backbone proto- col.

New features

Once the Ethernet interface is established, new features of monitoring systems become avail- able. Possibly the most useful is a Web server function. A Web server can be installed in the Communications Bridge/Gateway or in another Ethernet node so authorized personnel have desktop access to graphical representation of the gas monitoring system status. Graphical representation is no longer relegated to ex- pensive,

No heavy lifting here, it is all done for you.

Gordon Arnold is president of Sierra Monitor, a lead- ing manufacturer of

© 2004 by Sierra Monitor Corporation

Sierra Monitor Corporation 1991 Tarob Court Milpitas, CA 95035 USA (408)

Visit our Web site: www.sierramonitor.com |