Technical Reprint

Gas Detection Systems

How to make your facility's monitoring data accessible

by Gordon Arnold

You really have to have back- bone to survive in the safety monitoring world today. No, there is no heavy lifting re- quired. I am referring to the data backbone of the facility, plant or process to which the monitoring system is applied.

In times past, gas monitor- ing systems were

In addition to various proprietary data busses, some plant backbones are

A strong backbone

The challenge for industrial hygiene profes- sionals is to determine which backbone inter- face is required and then ensure that the se- lected equipment meets that requirement.

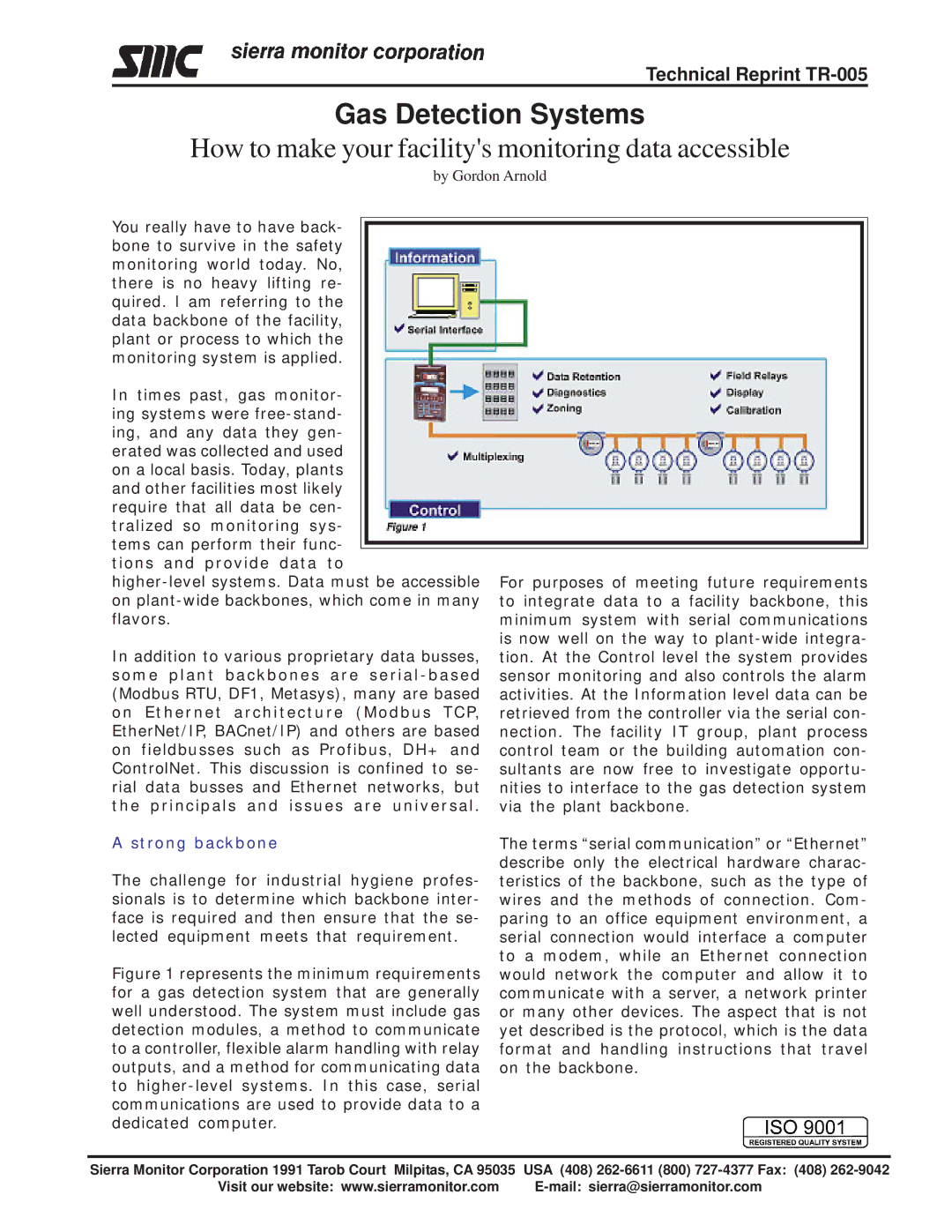

Figure 1 represents the minimum requirements for a gas detection system that are generally well understood. The system must include gas detection modules, a method to communicate to a controller, flexible alarm handling with relay outputs, and a method for communicating data to higher-level systems. In this case, serial communications are used to provide data to a dedicated computer.

For purposes of meeting future requirements to integrate data to a facility backbone, this minimum system with serial communications is now well on the way to plant-wide integra- tion. At the Control level the system provides sensor monitoring and also controls the alarm activities. At the Information level data can be retrieved from the controller via the serial con- nection. The facility IT group, plant process control team or the building automation con- sultants are now free to investigate opportu- nities to interface to the gas detection system via the plant backbone.

The terms “serial communication” or “Ethernet” describe only the electrical hardware charac- teristics of the backbone, such as the type of wires and the methods of connection. Com- paring to an office equipment environment, a serial connection would interface a computer to a modem, while an Ethernet connection would network the computer and allow it to communicate with a server, a network printer or many other devices. The aspect that is not yet described is the protocol, which is the data format and handling instructions that travel on the backbone.

Sierra Monitor Corporation 1991 Tarob Court Milpitas, CA 95035 USA (408)

Visit our website: www.sierramonitor.com |