Specifications and Safety | 2 |

DESCRIPTION

This Submersible Sump Pump is designed for home sumps. Unit is equipped with a

SPECIFICATIONS

Power supply required | ...........................115V, 60 HZ. |

Liquid Temp. Range | 32°F to |

Individual Branch Circuit Required (min.) ....15 Amps | |

Discharge | |

NOTICE: Do not reduce size of discharge pipe or hose below

Pump water only with this pump.

NOTICE: This unit is not designed as a waterfall or foun- tain pump, or for applications involving salt water or brine! Use with waterfalls, fountains, salt water or brine will void warranty.

Do not use where water recirculates.

Not designed for use as a swimming pool drainer.

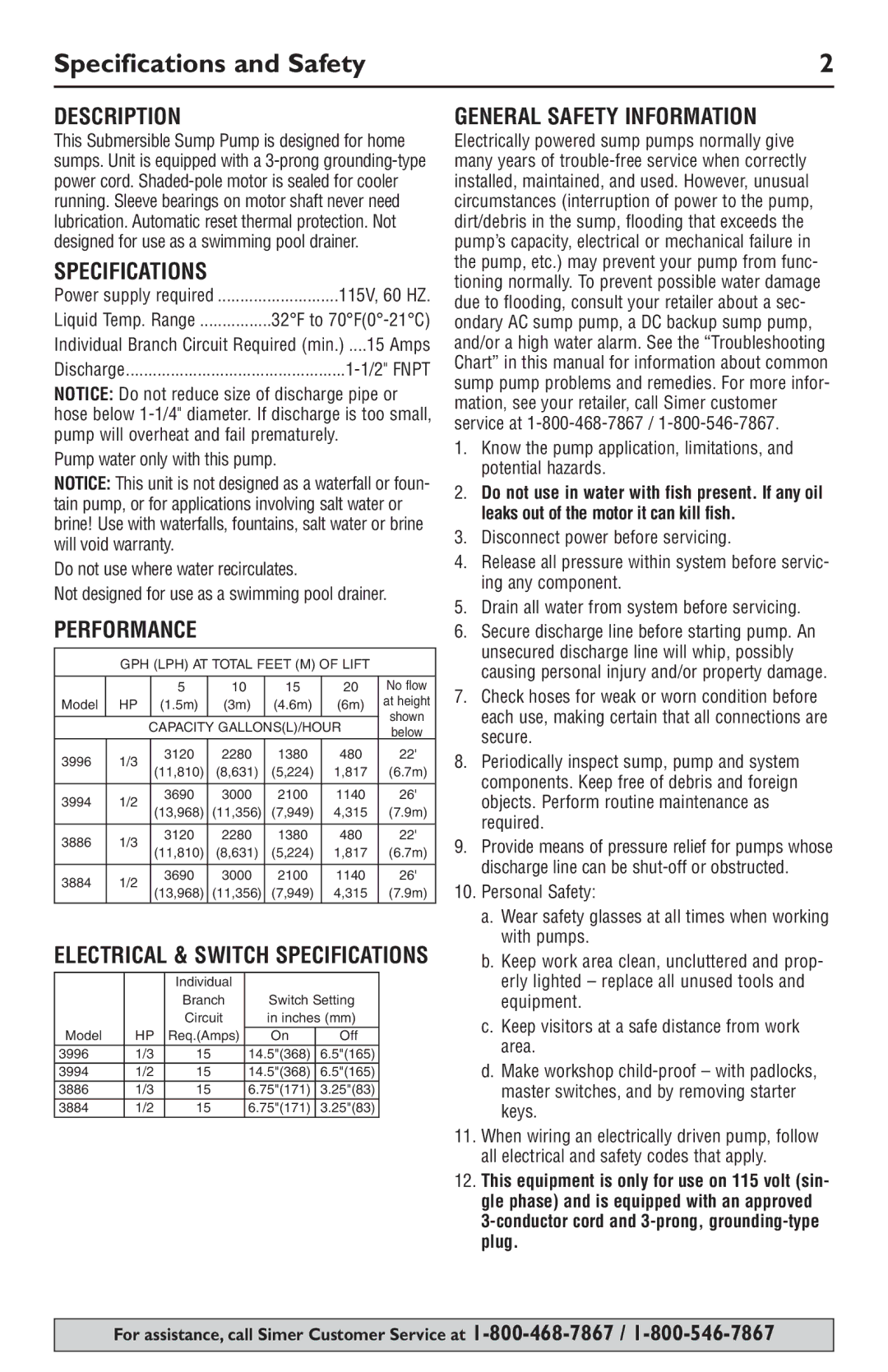

PERFORMANCE

GPH (LPH) AT TOTAL FEET (M) OF LIFT

|

|

| 5 | 10 | 15 | 20 | No flow | |

Model | HP | (1.5m) | (3m) | (4.6m) | (6m) | at height | ||

shown | ||||||||

|

|

|

|

|

|

| ||

|

| CAPACITY GALLONS(L)/HOUR | ||||||

|

| below | ||||||

|

|

|

|

|

|

| ||

3996 | 1/3 |

| 3120 | 2280 | 1380 | 480 | 22' | |

| (11,810) | (8,631) | (5,224) | 1,817 | (6.7m) | |||

|

|

| ||||||

|

|

|

|

|

|

|

| |

3994 | 1/2 |

| 3690 | 3000 | 2100 | 1140 | 26' | |

| (13,968) | (11,356) | (7,949) | 4,315 | (7.9m) | |||

|

|

| ||||||

|

|

|

|

|

|

|

| |

3886 | 1/3 |

| 3120 | 2280 | 1380 | 480 | 22' | |

| (11,810) | (8,631) | (5,224) | 1,817 | (6.7m) | |||

|

|

| ||||||

|

|

|

|

|

|

|

| |

3884 | 1/2 |

| 3690 | 3000 | 2100 | 1140 | 26' | |

| (13,968) | (11,356) | (7,949) | 4,315 | (7.9m) | |||

|

|

| ||||||

ELECTRICAL & SWITCH SPECIFICATIONS

|

| Individual |

|

|

|

| Branch | Switch Setting | |

|

| Circuit | in inches (mm) | |

Model | HP | Req.(Amps) | On | Off |

3996 | 1/3 | 15 | 14.5"(368) | 6.5"(165) |

3994 | 1/2 | 15 | 14.5"(368) | 6.5"(165) |

3886 | 1/3 | 15 | 6.75"(171) | 3.25"(83) |

3884 | 1/2 | 15 | 6.75"(171) | 3.25"(83) |

GENERAL SAFETY INFORMATION

Electrically powered sump pumps normally give many years of

1.Know the pump application, limitations, and potential hazards.

2.Do not use in water with fish present. If any oil leaks out of the motor it can kill fish.

3.Disconnect power before servicing.

4.Release all pressure within system before servic- ing any component.

5.Drain all water from system before servicing.

6.Secure discharge line before starting pump. An unsecured discharge line will whip, possibly causing personal injury and/or property damage.

7.Check hoses for weak or worn condition before each use, making certain that all connections are secure.

8.Periodically inspect sump, pump and system components. Keep free of debris and foreign objects. Perform routine maintenance as required.

9.Provide means of pressure relief for pumps whose discharge line can be

10.Personal Safety:

a.Wear safety glasses at all times when working with pumps.

b.Keep work area clean, uncluttered and prop- erly lighted – replace all unused tools and equipment.

c.Keep visitors at a safe distance from work area.

d.Make workshop

11.When wiring an electrically driven pump, follow all electrical and safety codes that apply.

12.This equipment is only for use on 115 volt (sin- gle phase) and is equipped with an approved

For assistance, call Simer Customer Service at