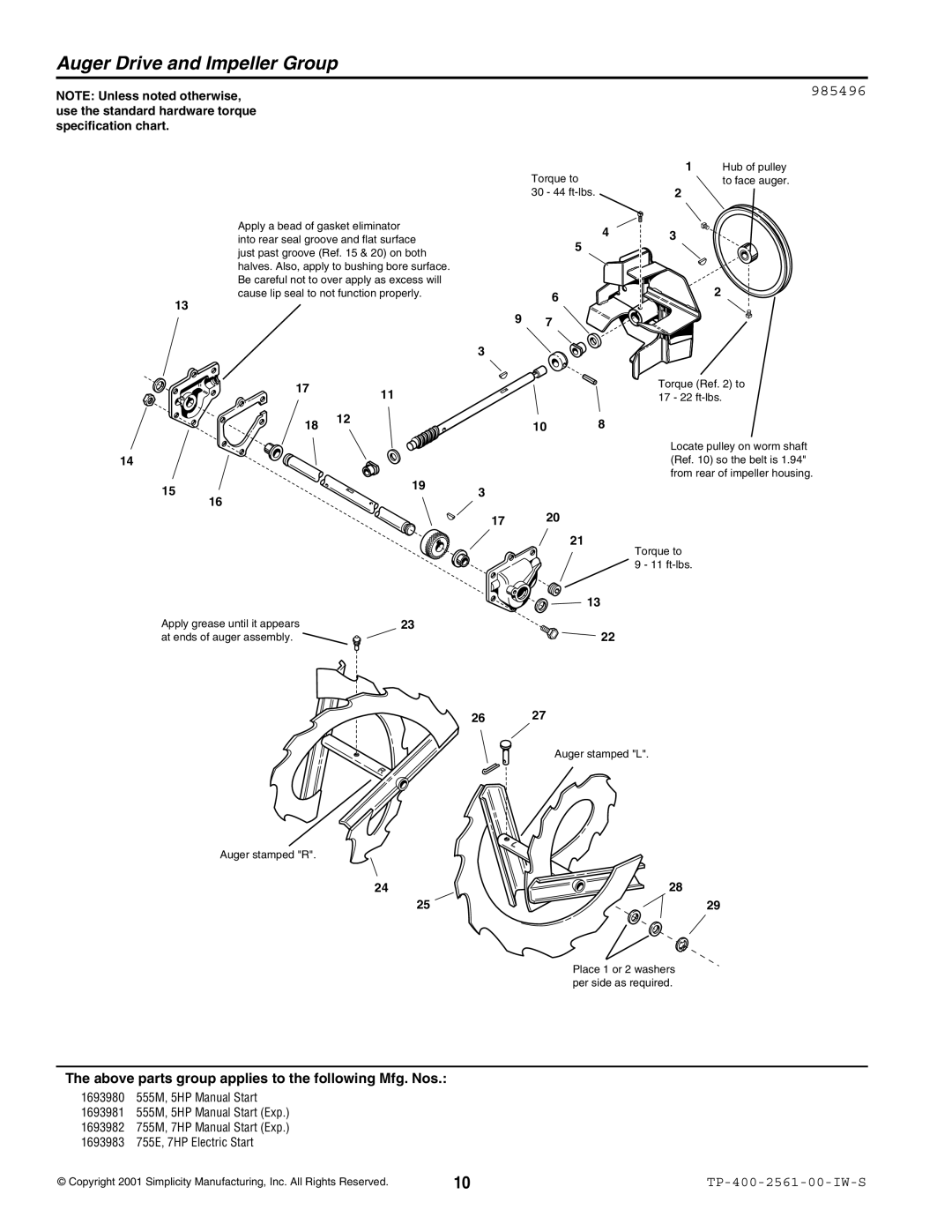

Auger Drive and Impeller Group

NOTE: Unless noted otherwise, | 985496 |

| |

use the standard hardware torque |

|

specification chart. |

|

Apply a bead of gasket eliminator into rear seal groove and flat surface just past groove (Ref. 15 & 20) on both halves. Also, apply to bushing bore surface. Be careful not to over apply as excess will cause lip seal to not function properly.

13

Torque to

30 - 44

4 |

5 |

| 6 |

9 | 7 |

3

1 Hub of pulley to face auger.

2

3 |

2 |

14 |

17 | 11 |

| |

18 | 12 |

|

10 | 8 |

Torque (Ref. 2) to 17 - 22

Locate pulley on worm shaft (Ref. 10) so the belt is 1.94" from rear of impeller housing.

15 |

16 |

3

17 | 20 |

21

Torque to

9 - 11

13

Apply grease until it appears | 23 |

at ends of auger assembly. |

|

22

26 | 27 |

Auger stamped "L".

Auger stamped "R".

24 |

| 28 |

25 | 29 |

Place 1 or 2 washers per side as required.

The above parts group applies to the following Mfg. Nos.:

1693980 555M, 5HP Manual Start

1693981 555M, 5HP Manual Start (Exp.)

1693982 755M, 7HP Manual Start (Exp.)

1693983 755E, 7HP Electric Start

© Copyright 2001 Simplicity Manufacturing, Inc. All Rights Reserved. | 10 |