Hardware Identification & Torque Specifications

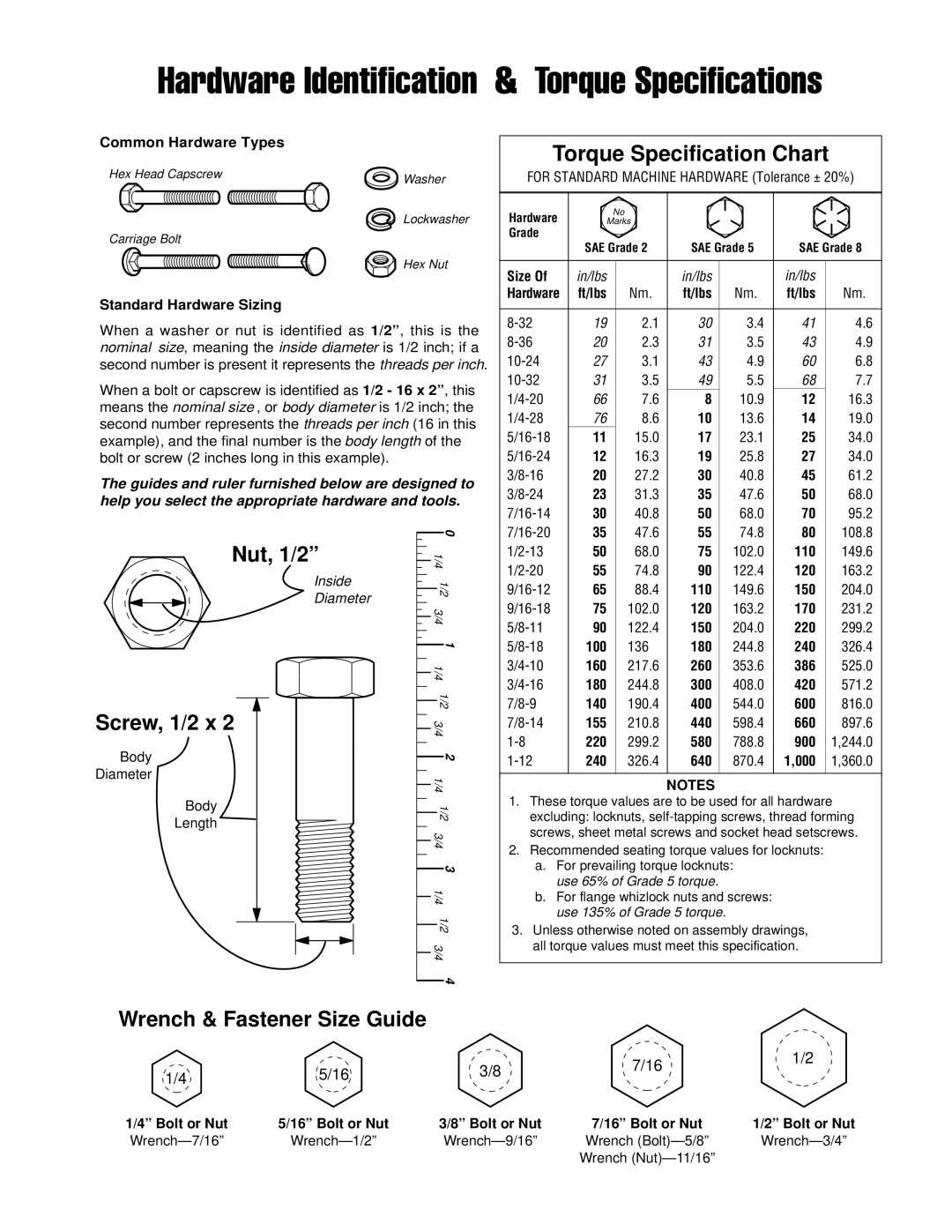

Common Hardware Types

Hex Head Capscrew | Washer |

| |

| Lockwasher |

Carriage Bolt |

|

| Hex Nut |

Standard Hardware Sizing

When a washer or nut is identified as 1/2”, this is the nominal size, meaning the inside diameter is 1/2 inch; if a second number is present it represents the threads per inch.

When a bolt or capscrew is identified as 1/2 - 16 x 2”, this means the nominal size , or body diameter is 1/2 inch; the second number represents the threads per inch (16 in this example), and the final number is the body length of the bolt or screw (2 inches long in this example).

The guides and ruler furnished below are designed to help you select the appropriate hardware and tools.

0

Nut, 1/2” | 1/4 | |

Inside | 1/2 | |

Diameter | ||

| ||

| 3/4 | |

| 1 | |

| 1/4 | |

Screw, 1/2 x 2 | 1/2 | |

3/4 | ||

Body | 2 | |

Diameter | 1/4 | |

| ||

Body | 1/2 | |

Length | ||

3/4 | ||

| ||

| 3 | |

| 1/4 | |

| 1/2 | |

| 3/4 | |

| 4 |

Torque Specification Chart

FOR STANDARD MACHINE HARDWARE (Tolerance ± 20%)

Hardware |

| No |

|

|

|

| |

Marks |

|

|

|

| |||

Grade | SAE Grade 2 | SAE Grade 5 | SAE Grade 8 | ||||

| |||||||

|

|

|

|

|

|

|

|

Size Of | in/lbs |

|

| in/lbs |

| in/lbs |

|

Hardware | ft/lbs |

| Nm. | ft/lbs | Nm. | ft/lbs | Nm. |

|

|

|

|

|

|

|

|

19 |

| 2.1 | 30 | 3.4 | 41 | 4.6 | |

20 |

| 2.3 | 31 | 3.5 | 43 | 4.9 | |

27 |

| 3.1 | 43 | 4.9 | 60 | 6.8 | |

31 |

| 3.5 | 49 | 5.5 | 68 | 7.7 | |

66 |

| 7.6 | 8 | 10.9 | 12 | 16.3 | |

76 |

| 8.6 | 10 | 13.6 | 14 | 19.0 | |

11 |

| 15.0 | 17 | 23.1 | 25 | 34.0 | |

12 |

| 16.3 | 19 | 25.8 | 27 | 34.0 | |

20 |

| 27.2 | 30 | 40.8 | 45 | 61.2 | |

23 |

| 31.3 | 35 | 47.6 | 50 | 68.0 | |

30 |

| 40.8 | 50 | 68.0 | 70 | 95.2 | |

35 |

| 47.6 | 55 | 74.8 | 80 | 108.8 | |

50 |

| 68.0 | 75 | 102.0 | 110 | 149.6 | |

55 |

| 74.8 | 90 | 122.4 | 120 | 163.2 | |

65 |

| 88.4 | 110 | 149.6 | 150 | 204.0 | |

75 |

| 102.0 | 120 | 163.2 | 170 | 231.2 | |

90 |

| 122.4 | 150 | 204.0 | 220 | 299.2 | |

100 |

| 136 | 180 | 244.8 | 240 | 326.4 | |

160 |

| 217.6 | 260 | 353.6 | 386 | 525.0 | |

180 |

| 244.8 | 300 | 408.0 | 420 | 571.2 | |

140 |

| 190.4 | 400 | 544.0 | 600 | 816.0 | |

155 |

| 210.8 | 440 | 598.4 | 660 | 897.6 | |

220 |

| 299.2 | 580 | 788.8 | 900 | 1,244.0 | |

240 |

| 326.4 | 640 | 870.4 | 1,000 | 1,360.0 | |

|

|

|

|

|

|

|

|

NOTES

1.These torque values are to be used for all hardware excluding: locknuts,

2.Recommended seating torque values for locknuts:

a.For prevailing torque locknuts: use 65% of Grade 5 torque.

b.For flange whizlock nuts and screws: use 135% of Grade 5 torque.

3.Unless otherwise noted on assembly drawings, all torque values must meet this specification.

Wrench & Fastener Size Guide

| 5/16 | 3/8 | 7/16 | 1/2 |

1/4 |

| |||

|

| |||

1/4” Bolt or Nut | 5/16” Bolt or Nut | 3/8” Bolt or Nut | 7/16” Bolt or Nut | 1/2” Bolt or Nut |

Wrench | ||||

|

|

| Wrench |

|