With a wide bladedscrewdriver, unscrewvalveplug (11).Take out air regulator(8)with

Reassembly

Clean all parts and examine for wear and replace any parts only with parts obtainedfrom the manufactureror an approved distributor. Ensurethat the faces of end plates (17) and (22) that abut cylinder(21) are flat andfree from burrs and surface defects. If necessary, lap on a flat very fine grade of abrasive paper.

Lightlycoat all parts In a suitablepneumatictool lubricating oil and pack bearingswith a lithium or molfldenum basedgeneralpurpose grease and reassemblein the reverse order.With the lever (12) depressedpour into hose adaptor (14) 5ml of a suitable pneumatictool lubricatingoil and releaseleverandconnect to a suitable air supply and operate toolslowly for a few seconds to allow the oil to circulate. Check the function of the collet, safety lever and air regulator before returning to service. Before fitting mounted point grinding wheel, check tool, the speed of the tool and the point

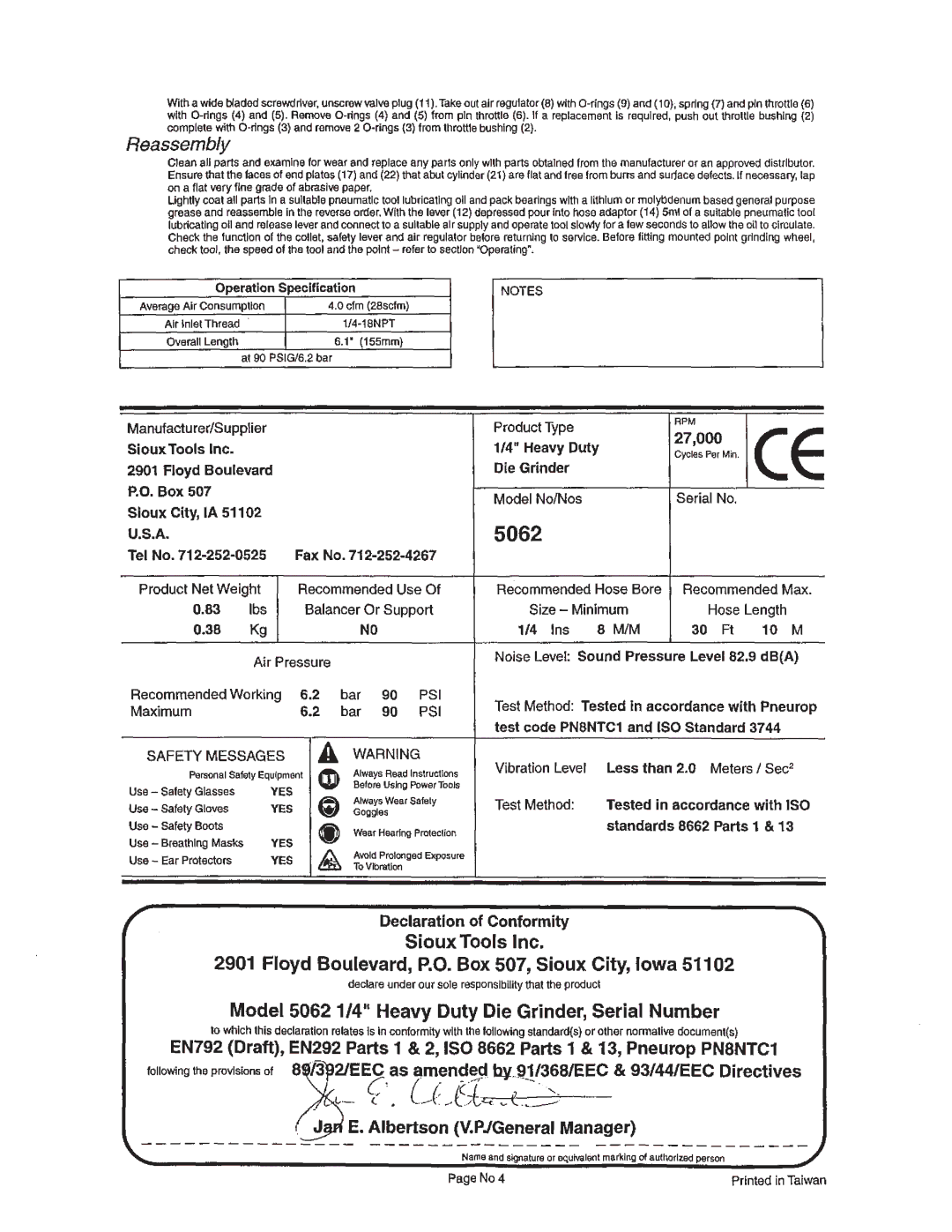

1 | Ooeration Soecification | 1 | NOTES | ||

| Average Air Consumption | 1 | 4.0 cfrn (28scfm) |

| |

| Air InlelThread | 1 |

| ||

| Overall Length | 1 | 6.1" | (155mm) |

|

at 90 PSIGt6.2 bar

SiouxTools Inc.

2901 Floyd Boulevard

P.O.Box 507

Sioux City, IA 51102

U.S.A.

Tel No.

Product Net Weight Recommended Use Of

0.83Ibs 1 Balancer Or Support

| Air Pressure |

| |||

RecommendedWorking | 6.2 | bar 90 PSI | |||

Maximum |

| 6.2 | bar 90 PSI | ||

SAFETY MESSAGES |

| 1 | A WARNING | ||

PersonalSafety Equipment |

| Always Read Inslructfons | |||

Use | VES |

|

| Before Using PowerTools | |

|

| Always Wear Safety | |||

YES |

| 1 | @ Goggles | ||

Use - Safety Boots |

|

| ffi W W Hearing~ Protac!ion | ||

Use | YES |

| |||

Use - Ear Protectors |

|

| I |

| ATOMProlonged Exposure |

|

|

| ÇVlbrat | ||

|

|

|

| ||

ProductType | RPM | ce |

| ||

27000 |

| |

114" Heavy Duty |

| |

Cycles Per Min. |

| |

Die Grinder |

|

|

Model No/Nos | ISerialNo. |

|

|

|

Size - Minimum | Hose Length |

Noise Level: Sound Pressure Level 82.9 dB(A)

Test Method: Tested in accordance with Pneurop test code PN8NTC1 and IS0 Standard 3744

Vibration Level Less than 2.0 Meters 1 Sec2

Test Method: Tested in accordance with IS0 standards 8662 Parts 1 & 13

Declarationof Conformity

SiouxTools Inc.

2901 Floyd Boulevard. P.O. Box 507, Sioux City. Iowa 51102

declare under our sole responsibility lhat the product

Model 5062 114" Heavy Duty Die Grinder, Serial Number

to which this declaration relates Is in conformitywith the followingstandard(s) or other normative document(s)

EN792 (Draft), EN292 Parts 1 & 2, IS0 8662 Parts 1 & 13, Pneurop PN8NTC1

following ~~O~~OVIS~OIISof |

| & 9 3 1 4 4 1 Directives~ ~ ~ |

| (V.PJGeneral Manager) | |

< | Name and signature or aquhffllent marking of authorliedperson | |

| ¥à | |

Page No 4 | Printed inTaiwan |