Model 5264 & 5266

Lever Style Needle ScalerIChipper

Form # Z495

Date

7 IMPORTANT

..

Read these instructions carefully before installing,operating,servicing or repairingthis tool. Keep these instructions in a safe accessible place.

1 | SAFETY MESSAGES | 1 | A WARNING |

|

|

| 1 | Operator Instructions | ||

| Personal Safety Equipment | 1 | @ | Always Read Instructions Before | 1 | Includes: | ||||

Use | YES | Using Power Tools |

| Safety Rules | ||||||

Use - Safety Gloves | YES |

| (^ Always Wear Safety Goggles | ores seen Use | ||||||

Use |

|

| @ Wear Hearing Protection |

|

| Work Stations | ||||

|

|

|

| Putting Into Service | ||||||

Use | YES |

|

|

| ||||||

| A | Avoid Prolonged Exposure |

| Operating | ||||||

Use - Ear Protectors | YES |

|

| |||||||

| To Vibration |

|

|

|

| Dismantling and Assembly. | ||||

| Safety rules when using a 5264 & 5266 Needle ScalerIChipper | |||||||||

- Always wear safety goggles. |

|

|

|

|

| local, regional or country legal requirements when | ||||

- | Prolonged exposure to vibration may cause injury. | - | installing, usingor maintainingthe tool. | |||||||

- | Readallinstructionsbeforeusingthistool.All operators must | Take care that the exhaust air does not point towards any | ||||||||

- | be fully trained in its useand awareof these safety rules. |

| other person or material or substance that could be | |||||||

Do not exceed the maximum working air pressure. |

| contaminated by oil droplets. When first lubricating a tool | ||||||||

- | Use personal protectionequipment as recommended. |

| or if the tool exhaust has a high oil content, do not allow | |||||||

- | Some dust created by power sanding, sawing, grinding, | - | the exhaust air to come near very hot surfaces or flames. | |||||||

| drilling, and other construction activities contains | Never lay the tool down until the working attachmenthas | ||||||||

| chemicalsknownto causecancer, birthdefectsandother | - | stoppedmoving. |

| ||||||

- | reproductive harm. |

|

|

|

| When the tool is not in use, shut off the air supply and | ||||

Usecompressedair only at the recommendedconditions. |

| press throttle triggerhever to drain the supply line. If the | ||||||||

- | If the tool appears to malfunction, remove from use |

| tool is not to be used for a oeriod of time. first lubricate. | |||||||

| immediately and arrangefor service and repair. If it is not |

| disconnectfrom air supply andstore ina dry average room | |||||||

| practicalto removetool from service, then shut off the air | - | temperature environment. | |||||||

| supply to the tool and write or have written a warning | If the tool is passed from one user to a new or inexperi- | ||||||||

- | note and attach it to the tool. |

|

|

|

|

| enced user, make sure these instructionsare available to | |||

If tool is to be used with a balancer or other suspension | - | be passedwith the tool. | ||||||||

| device, ensure that the tool is firmly attached to the | Do not remove any manufacturer fitted safety devices | ||||||||

- | suspension/supportdevice. |

|

|

|

|

| where fitted, i.e., | wheel guards, safety trigger, speed | ||

When operating the tool, always keep the body and |

| governors, etc. |

|

| ||||||

| particularlythe handsaway from the workingattachment | - Wherever possible, secureworkpiece with clamps, a vise, | ||||||||

- | ixed to the tool. |

|

|

|

|

| etc. to make it rigid so it does not move during the work | |||

The tool is not electricallyinsulated. Never use the tool if |

| operation. Keep good balance at all times. Do not stretch | ||||||||

| there is any chance of coming into contact with live | - | or overreach. |

|

| |||||

- | electricity. |

|

|

|

| Try to matchthe tool to the work operation. Do not use a | ||||

Always when using the tool, adopt a firm footing and/or |

| tool that is too light or heavy for the work operation. If in | ||||||||

| position and rip the tool sufficiently only to overcome | - | doubt, seek advice. | |||||||

| any reaction forces that may result from the tool doing | In general terms, this tool is not suitable for underwater | ||||||||

- | work. Do not overgrip. |

|

|

|

|

| use or usein explosive environments | |||

Use only correct spare partsfor maintenanceand repair. |

| manufacturer. |

|

| ||||||

| Do not improvise or make temporary repairs. Major | - Try to make sure that the work area is clear to enable the | ||||||||

| servicing and repairs should only be carried out by |

| work task to be performed safely. If practical and | |||||||

- | persons trained to do so. |

|

|

|

|

| possible, try to clear unnecessary obstructions before | |||

Do not lock, tape, wire, etc. the 'OnIOff'valve in 'On' |

| starting work. |

|

| ||||||

| position.The throttle tri gertlever, etc. must always be free | - Always use air hose and couplings with minimum work- | ||||||||

| to return to the '6ft'position when released. |

| ing pressure ratings at least 1 112 times the maximum | |||||||

- blwa s shut off the air supply to the tool and press the |

| working pressure rating of the tool. | ||||||||

| On/8ff1valve to exhaust the air from the feed hose |

|

|

|

|

| ||||

| beforefitting, removingor adjustingthe |

|

|

|

|

|

|

|

| |

| workina attachment fitted to the tool. |

|

|

|

|

|

|

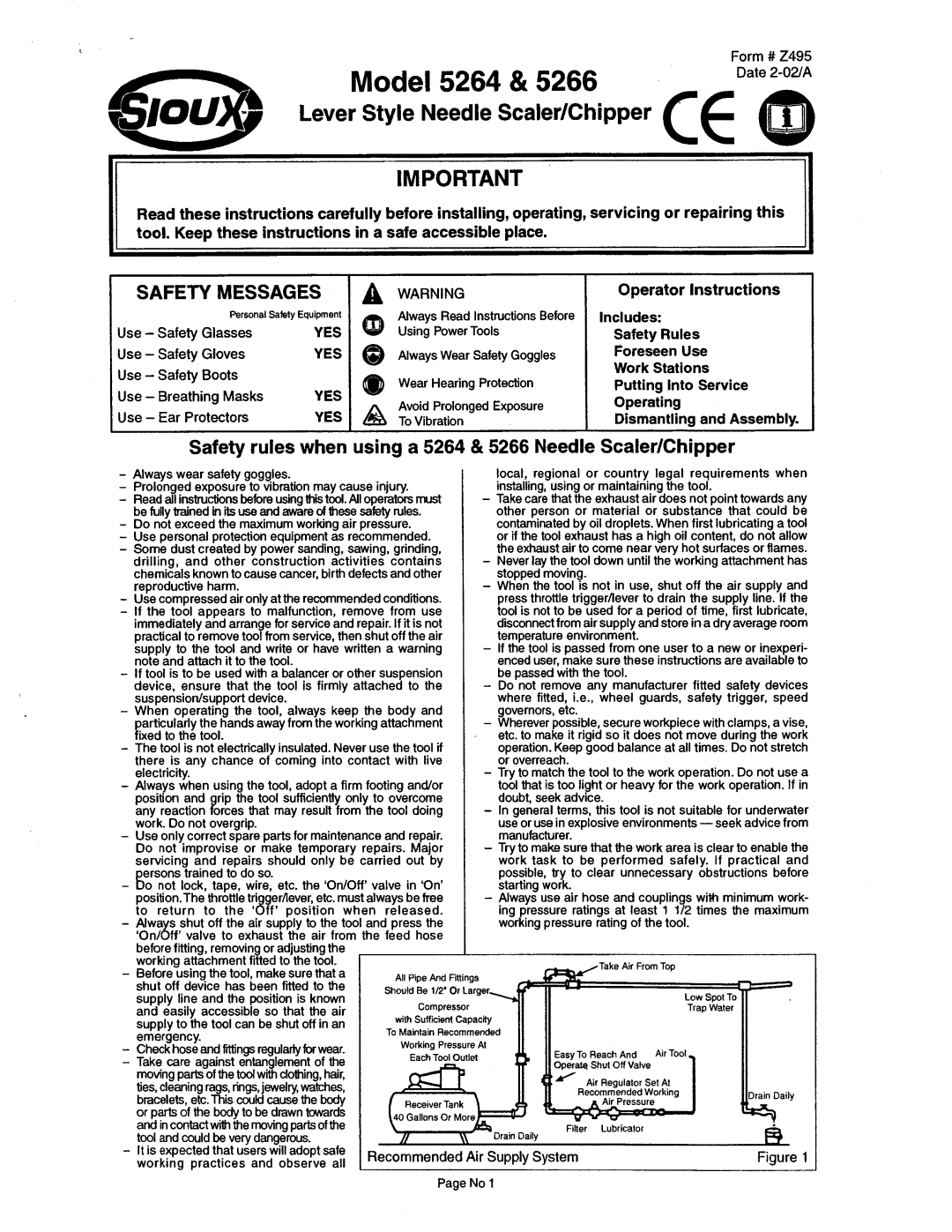

| Take Air FromTop | |

- ~eforeusingthe tool, make sure that a |

|

| All PipeAnd Fittings |

|

|

|

| |||

|

|

|

|

|

|

| ||||

| shut off device has been fitted to the |

| Should Be 112"Or Larger | , |

|

|

| |||

| supply line and the position is known |

|

| Compressor |

|

|

|

|

| |

| and easily accessible so that the air |

|

|

|

|

|

|

| ||

|

|

| with Sufficient Capacity |

|

|

|

| |||

| supply to the tool can be shut off in an |

|

|

|

|

|

| |||

|

|

| To Maintain Recommended 11 | 11 |

| 11 | ||||

| emergency. |

|

|

|

| |||||

- |

|

|

| Workina Pressure At | 11 | 11 |

|

| ||

Checkhoseandfittings regulartyfor wear. |

|

|

|

| ||||||

- Take care against entanglement of the |

|

|

|

|

|

|

|

| ||

| moving partsof the toolwithclothing,hair, |

|

|

|

|

|

|

|

| |

| ties, cleaningrags, rings,jewelry,watches, |

|

|

|

|

|

|

|

| |

| bracelets,etc.This couldcause the body |

|

|

|

|

|

|

|

| |

| or parts of the body to be drawn towards |

|

|

|

|

|

|

|

| |

| and incontactwiththemovingpartsof the |

|

|

|

|

|

|

|

| |

- | tool andcould be very dangerous. |

|

| 1 Recommended Air Supply System |

|

| ||||

It is expectedthat userswill adoptsafe |

|

| Figure 1 | |||||||

| working practices and observe all |

|

|

|

|

|

|

|

| |

Page No 1