Form # ZCE705

Date

Operator Instructions

Indudes - Foreseen Use,Work Stations, Putting Into Service,

Operating,Dismantling,Assembly and Safety Rules.

Manufacturer/Supplier

SiouxTools, Inc.

250

P.O. Box 1596

Murphy, NC 28906

Important

Read these instructions carefully before installing, operating, servicingor repairingthis toot. Keepthese instructions in a sate accessible place.

ProductType | Max BPM |

|

High Speed Air Saw | 11,000 |

| |

Model NoINos | Serial No. |

U.S. A. |

|

|

|

| 5300A |

|

| |

Tel No. | Fax No. |

|

| |||||

|

|

| ||||||

Product NetWeight | Recommended Use Of | RecommendedHose Bore | Recommended Max. | |||||

1.75 lbs | Balancer Or Support | Size - Minimum | Hose Length | |||||

0.80 kg |

| NO |

|

| 5/16 ins 8 mrn | 3 0 F t | 10M | |

|

|

|

| |||||

Air Pressure |

|

|

| Noise Level: Sound Pressure Level | 82.0 dB(A) | |||

|

|

| Sound Power Level | 94.0 dB(A) | ||||

|

|

|

|

| ||||

RecornrnendedWorking | 6.2 | bar | 90 | PSI | Test Method: Tested in accordance with Pneurop | |||

Maximum | 6.2 | bar | 90 | PSI | ||||

test code | ||||||||

|

|

|

|

| ||||

SAFETY MESSAGES | 1 A WARNING |

| Vibration Level | 10.1 Meters / Sec2 | ||||

Personal Safety Equipment |

|

|

|

|

|

|

| |

Use - SafetyGlasses

Use - SafetyGloves

Use

Use

use- ~ a ProtectmrYES &,

Test Method: Tested in accordance with I S 0

standards 8662 Part 1 & 12

ear baring Protection

Avoid Prolonged Exposure

Tovhtw

Safety rules when using a 5300A Air

Saw

-Prolonged exposure to vibration may cause injury.

-Use personal protection equipment as recommended.

-Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

suspension/support device.

-Always when using the tool. adopt a firm footing and/or position and grip the tool sufficiently only to overcome any reaction forces that may result from the tool doing

work. Do not ove&rip.

chemicalsknown to cause cancer, birth defects and other reproductive harm.

-Use only compressed air at the

recommended conditions.

If the tool appears to malfunction. remove from use immediately and arrange for service and repair. If it is not practical to remove tool from service, then shut off the air supply to the tool and write or have written a warning note and attach it to the tool.

-If tool is to be used with a balanceror other suspension device, ensure that the tool is firmly attached to the

,

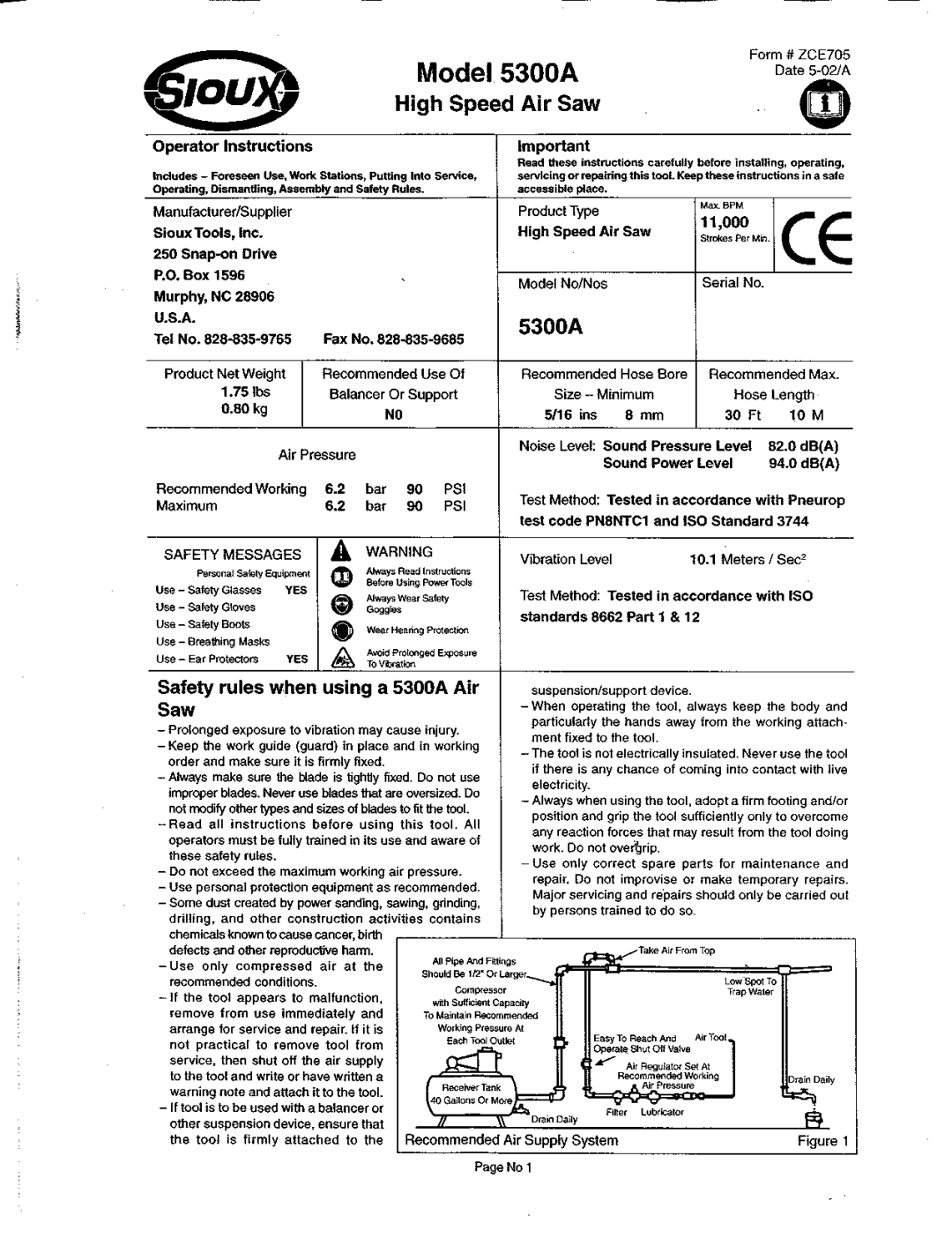

All Pipe And Fitinas | Take Air From Top | |

| ||

Should Be l/a- Or Larger | LOTISpO!To | |

Compressor | ||

Trap Water | ||

with Sufficient Capacity |

|

1RecommendedAir Supply System | Figure 1 |

Page No 1 |

|