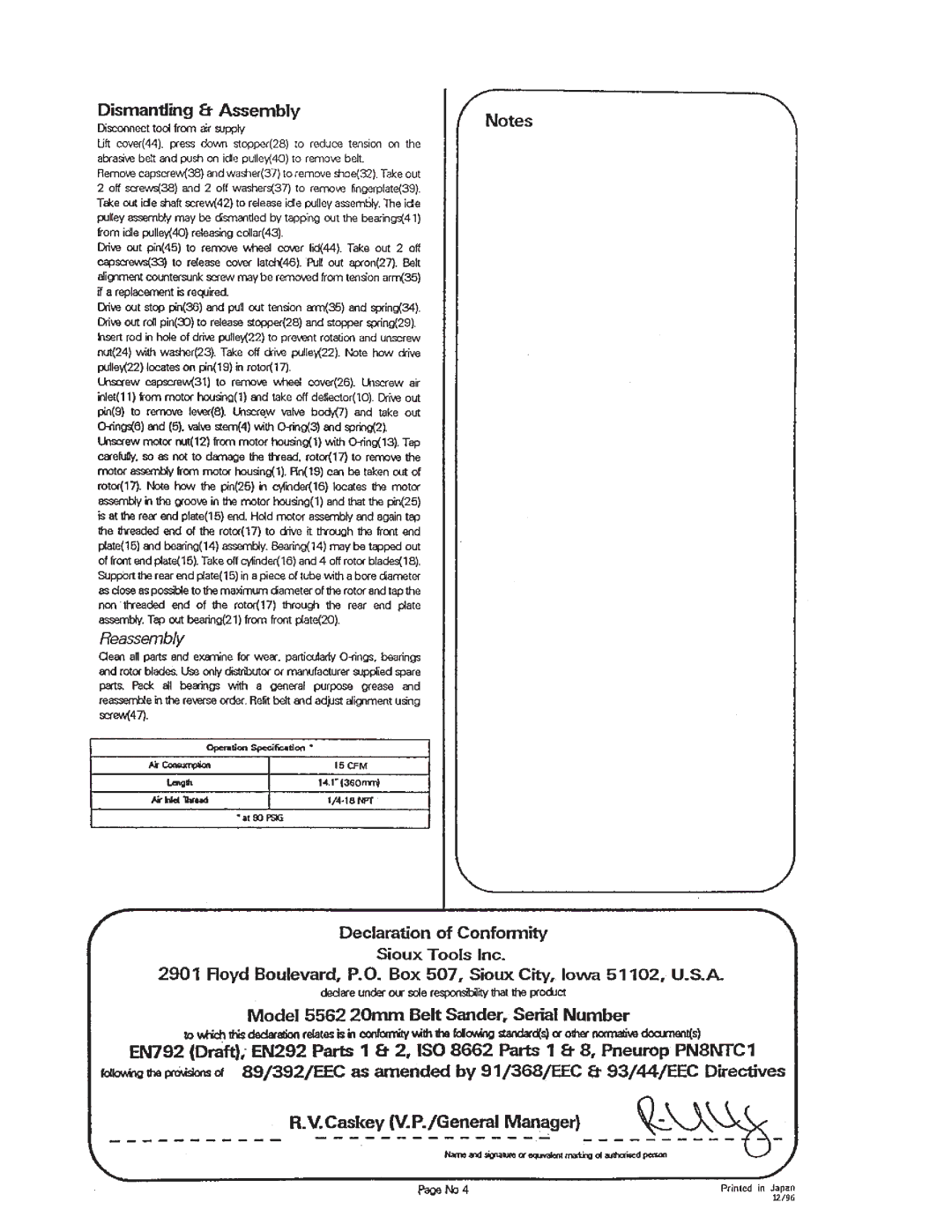

5562 specifications

Sioux Tools 5562 is a remarkable air tool designed for heavy-duty applications, particularly suited for professionals in various industries, including automotive, construction, and manufacturing. Known for its durable build and exceptional performance, the Sioux Tools 5562 stands out due to its advanced features and cutting-edge technologies that enhance efficiency and comfort.One of the main characteristics of the Sioux Tools 5562 is its robust construction. Built from high-quality materials, this tool is engineered to withstand rigorous usage, ensuring longevity and reliability. The casing is designed to resist wear and tear, contributing to the tool's overall durability. Combined with its lightweight design, the Sioux 5562 allows for prolonged use without causing fatigue, making it ideal for demanding work environments.

The Sioux Tools 5562 boasts an impressive power-to-weight ratio. Equipped with a powerful motor, it delivers high torque output, enabling users to handle various tasks with ease. Its variable speed control feature allows for precise operation, making it versatile enough for different applications, from intricate assembly work to heavy-duty bolting tasks. This flexibility ensures that professionals can adapt the tool to their specific needs without compromising performance.

One of the standout technologies integrated into the Sioux Tools 5562 is its ergonomic design. The tool features a comfortable grip that reduces vibration and provides excellent control, even during extended use. Additionally, it includes a built-in silencing mechanism that minimizes noise levels, creating a more pleasant work environment and reducing the risk of hearing damage for users.

Safety is also a top priority for Sioux Tools, and the 5562 reflects this commitment. It includes several safety features such as a built-in exhaust system that directs air away from the user, ensuring a cleaner and safer operating experience. The safety latch prevents accidental activation, providing peace of mind while using the tool.

In summary, the Sioux Tools 5562 is a high-performance air tool that combines rugged construction, advanced technologies, and user-friendly features. Its powerful motor, variable speed control, ergonomic design, and safety mechanisms make it an essential addition to any professional toolkit. With the Sioux Tools 5562, users can expect a reliable tool that enhances productivity and facilitates a wide range of applications in diverse work settings.