SM 2610948279

STRAIGHT CUTTING

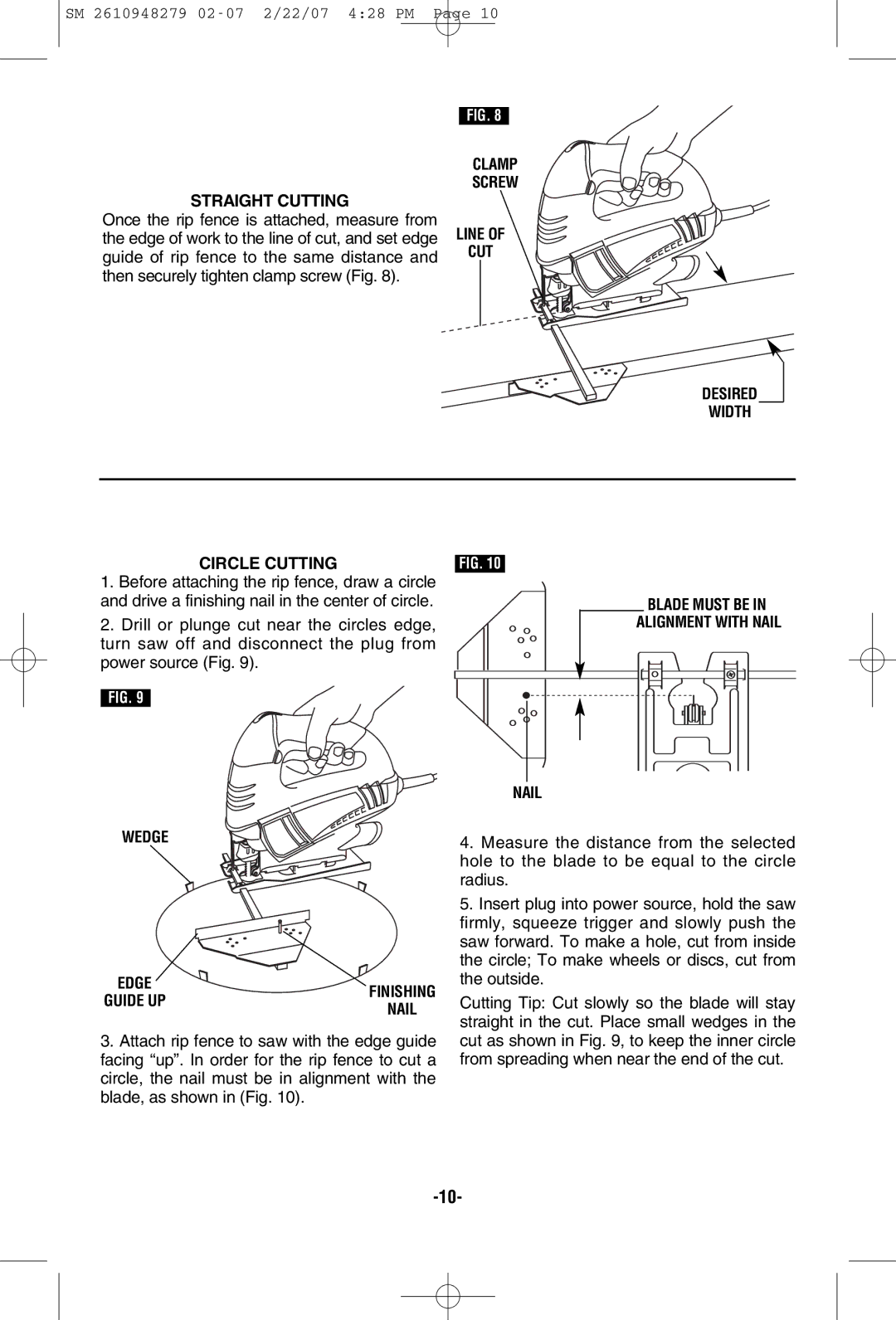

Once the rip fence is attached, measure from the edge of work to the line of cut, and set edge guide of rip fence to the same distance and then securely tighten clamp screw (Fig. 8).

FIG. 8

CLAMP

SCREW

LINE OF

CUT

DESIRED

WIDTH

CIRCLE CUTTING

1.Before attaching the rip fence, draw a circle and drive a finishing nail in the center of circle.

2.Drill or plunge cut near the circles edge, turn saw off and disconnect the plug from power source (Fig. 9).

FIG. 9

WEDGE

EDGE | FINISHING | |

GUIDE UP | ||

NAIL | ||

|

3.Attach rip fence to saw with the edge guide facing “up”. In order for the rip fence to cut a circle, the nail must be in alignment with the blade, as shown in (Fig. 10).

FIG. 10

BLADE MUST BE IN

ALIGNMENT WITH NAIL

NAIL

4.Measure the distance from the selected hole to the blade to be equal to the circle radius.

5.Insert plug into power source, hold the saw firmly, squeeze trigger and slowly push the saw forward. To make a hole, cut from inside the circle; To make wheels or discs, cut from the outside.

Cutting Tip: Cut slowly so the blade will stay straight in the cut. Place small wedges in the cut as shown in Fig. 9, to keep the inner circle from spreading when near the end of the cut.