SM 2610938738

SM 2610938738 03-06 3/10/06 9:28 AM Page 7

|

| Assembly |

| |

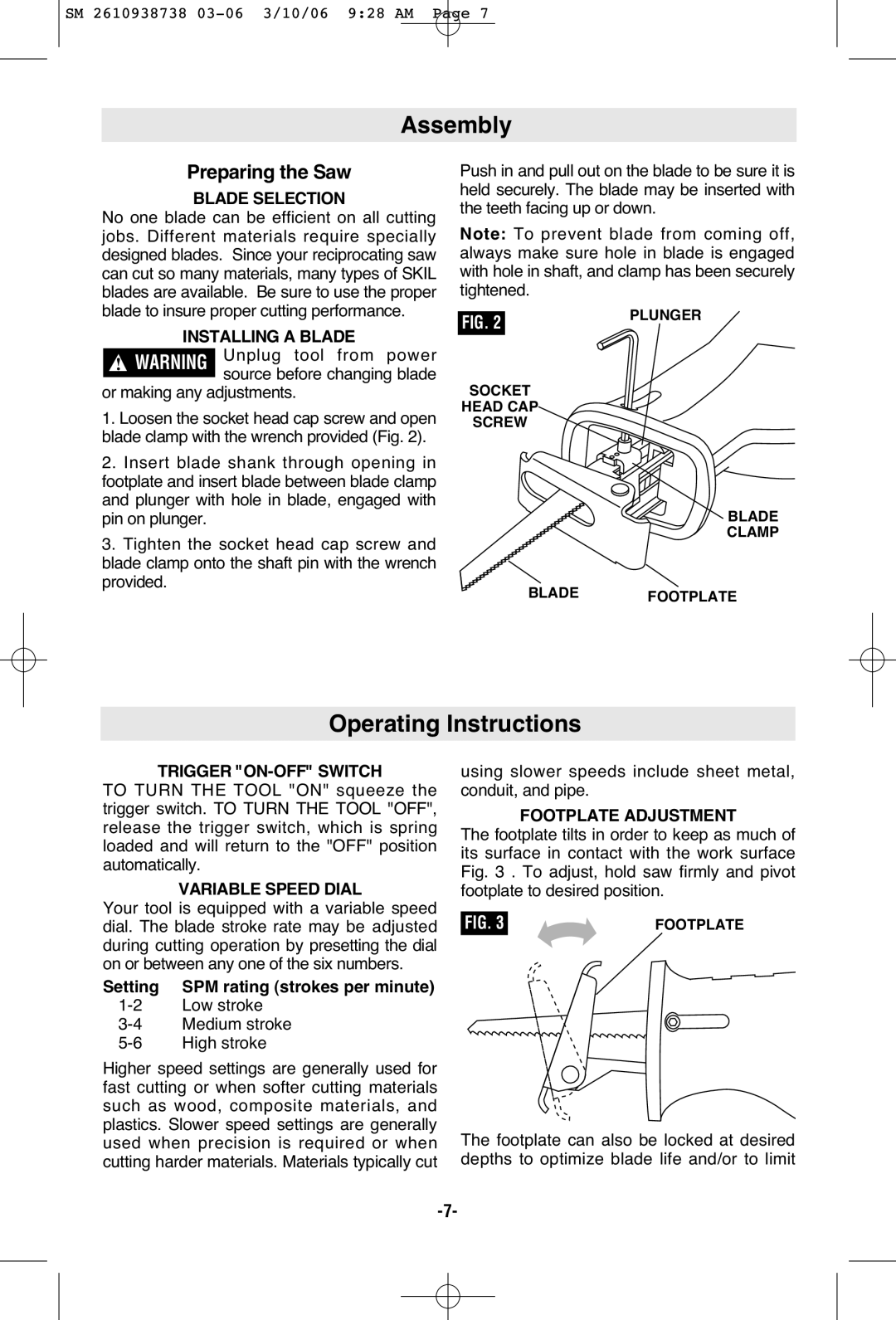

| Preparing the Saw | Push in and pull out on the blade to be sure it is | ||

| BLADE SELECTION | held securely. The blade may be inserted with | ||

No one blade can be efficient on all cutting | the teeth facing up or down. | |||

jobs. Different materials require specially | Note: To prevent blade from coming off, | |||

designed blades. Since your reciprocating saw | always make sure hole in blade is engaged | |||

can cut so many materials, many types of SKIL | with hole in shaft, and clamp has been securely | |||

blades are available. Be sure to use the proper | tightened. |

| ||

blade to insure proper cutting performance. |

| PLUNGER | ||

| INSTALLING A BLADE | FIG. 2 | ||

! | WARNING | Unplug tool from power |

|

|

| source before changing blade | HEAD CAP |

| |

or making any adjustments. |

| |||

1. Loosen the socket head cap screw and open | SOCKET |

| ||

SCREW |

| |||

blade clamp with the wrench provided (Fig. 2). |

|

| ||

2. Insert blade shank through opening in |

|

| ||

footplate and insert blade between blade clamp |

|

| ||

and plunger with hole in blade, engaged with |

| BLADE | ||

pin on plunger. |

|

| ||

3. Tighten the socket head cap screw and |

| CLAMP | ||

blade clamp onto the shaft pin with the wrench | BLADE | FOOTPLATE | ||

provided. |

| |||

Operating Instructions

TRIGGER "ON-OFF" SWITCH

TO TURN THE TOOL "ON" squeeze the trigger switch. TO TURN THE TOOL "OFF", release the trigger switch, which is spring loaded and will return to the "OFF" position automatically.

VARIABLE SPEED DIAL

Your tool is equipped with a variable speed dial. The blade stroke rate may be adjusted during cutting operation by presetting the dial on or between any one of the six numbers.

Setting SPM rating (strokes per minute)

Higher speed settings are generally used for fast cutting or when softer cutting materials such as wood, composite materials, and plastics. Slower speed settings are generally used when precision is required or when cutting harder materials. Materials typically cut

using slower speeds include sheet metal, | |

conduit, and pipe. | |

| FOOTPLATE ADJUSTMENT |

The footplate tilts in order to keep as much of | |

its surface in contact with the work surface | |

Fig. 3 . To adjust, hold saw firmly and pivot | |

footplate to desired position. | |

FIG. 3 | FOOTPLATE |

The footplate can also be locked at desired depths to optimize blade life and/or to limit