SM 2610947884

Assembly

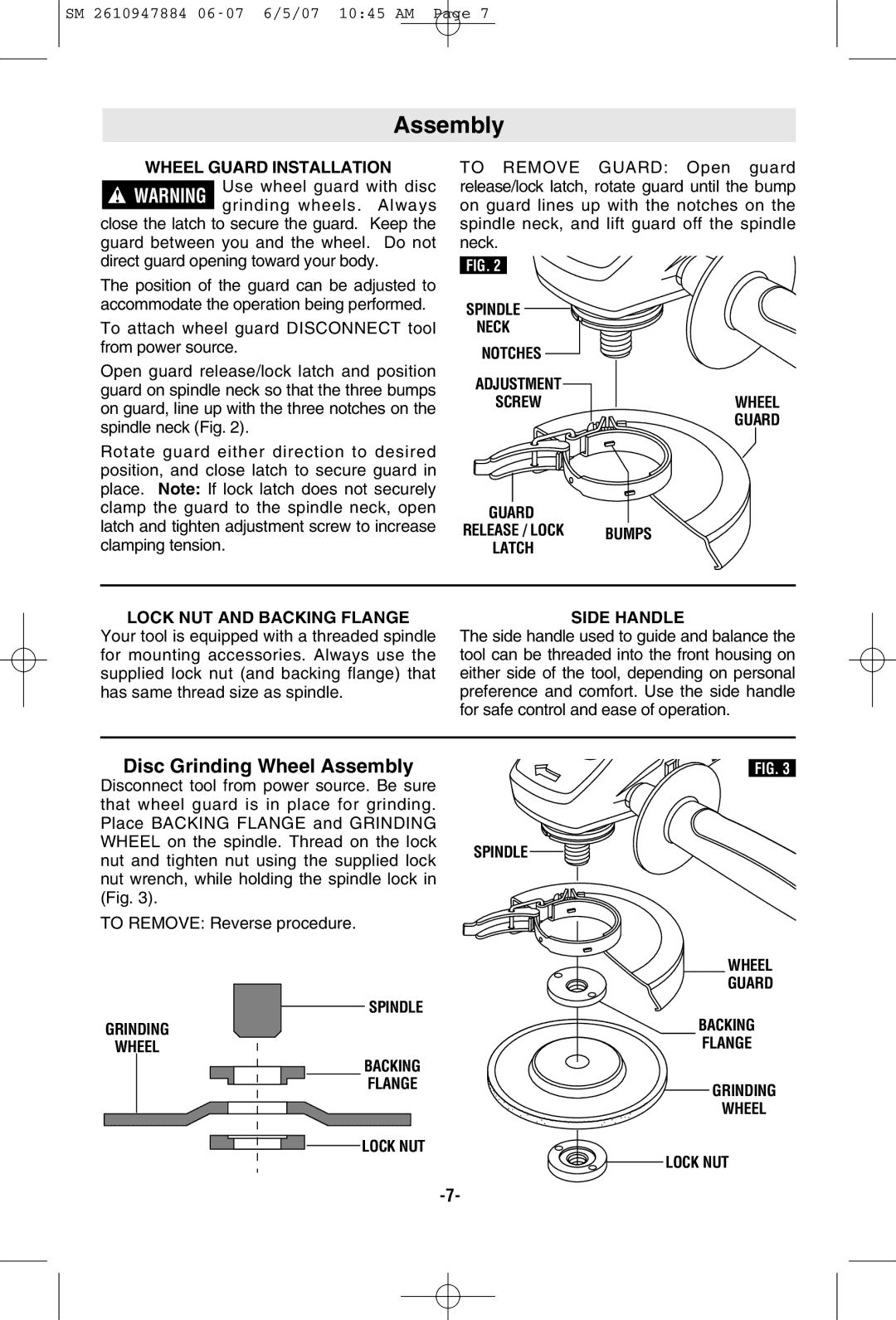

WHEEL GUARD INSTALLATION

!Use wheel guard with disc WARNING grinding wheels. Always

close the latch to secure the guard. Keep the guard between you and the wheel. Do not direct guard opening toward your body.

The position of the guard can be adjusted to accommodate the operation being performed.

To attach wheel guard DISCONNECT tool from power source.

Open guard release/lock latch and position guard on spindle neck so that the three bumps on guard, line up with the three notches on the spindle neck (Fig. 2).

Rotate guard either direction to desired position, and close latch to secure guard in place. Note: If lock latch does not securely clamp the guard to the spindle neck, open latch and tighten adjustment screw to increase clamping tension.

TO REMOVE GUARD: Open guard release/lock latch, rotate guard until the bump on guard lines up with the notches on the spindle neck, and lift guard off the spindle neck.

FIG. 2

SPINDLE |

|

NECK |

|

NOTCHES |

|

ADJUSTMENT |

|

SCREW | WHEEL |

| GUARD |

GUARD

RELEASE / LOCK BUMPS

LATCH

LOCK NUT AND BACKING FLANGE

Your tool is equipped with a threaded spindle for mounting accessories. Always use the supplied lock nut (and backing flange) that has same thread size as spindle.

SIDE HANDLE

The side handle used to guide and balance the tool can be threaded into the front housing on either side of the tool, depending on personal preference and comfort. Use the side handle for safe control and ease of operation.

Disc Grinding Wheel Assembly

Disconnect tool from power source. Be sure that wheel guard is in place for grinding. Place BACKING FLANGE and GRINDING WHEEL on the spindle. Thread on the lock nut and tighten nut using the supplied lock nut wrench, while holding the spindle lock in (Fig. 3).

TO REMOVE: Reverse procedure.

SPINDLE

GRINDING

WHEEL

BACKING

FLANGE

![]()

![]()

![]()

![]()

![]() LOCK NUT

LOCK NUT

FIG. 3

SPINDLE ![]()

![]()

WHEEL

GUARD

![]() BACKING

BACKING

FLANGE

![]() GRINDING

GRINDING

WHEEL