Hardware Identification & Torque Specifications

Common Hardware Types

Hex Head Capscrew | Washer |

| |

| Lockwasher |

Carriage Bolt |

|

| Hex Nut |

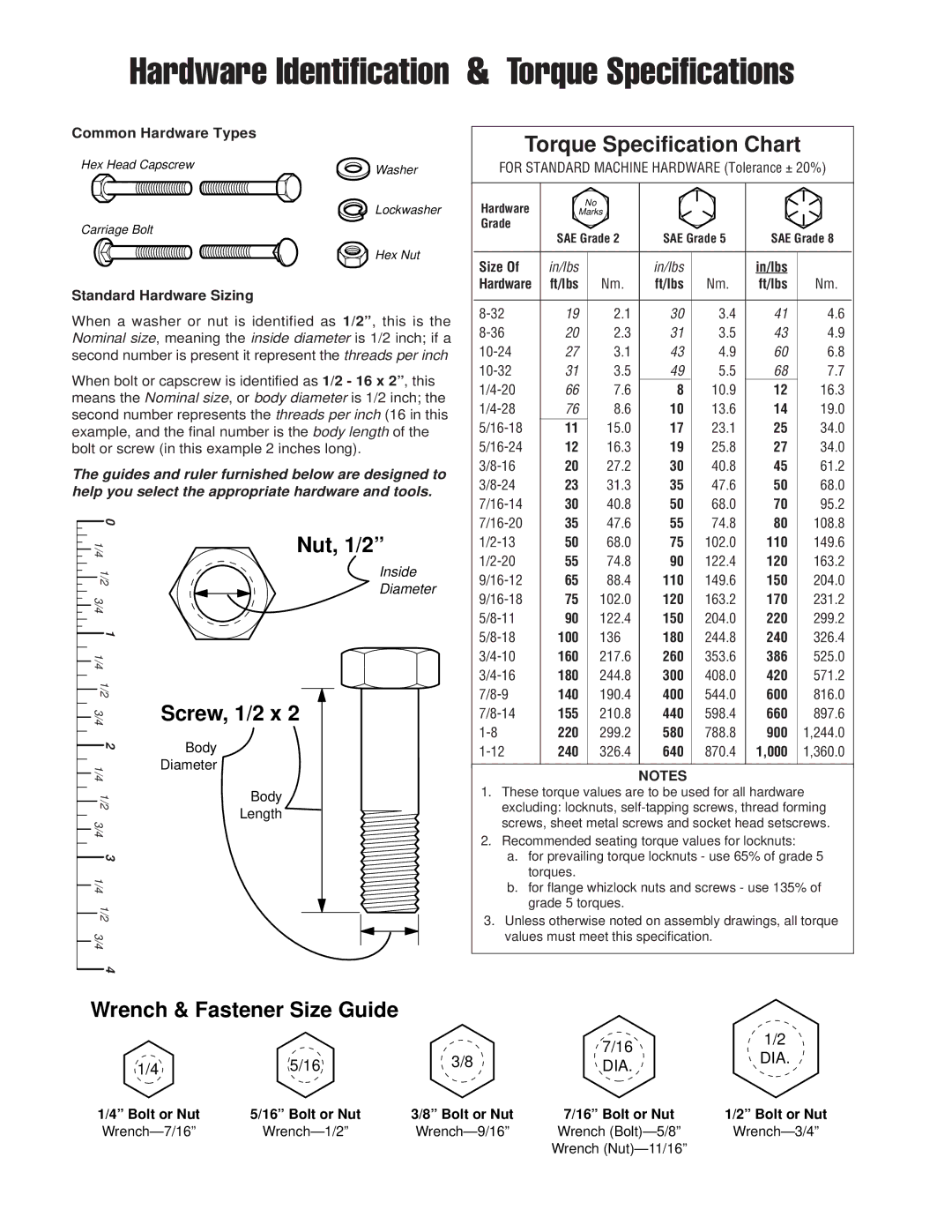

Standard Hardware Sizing

When a washer or nut is identified as 1/2” , this is the Nominal size, meaning the inside diameter is 1/2 inch; if a second number is present it represent the threads per inch

When bolt or capscrew is identified as 1/2 - 16 x 2” , this means the Nominal size, or body diameter is 1/2 inch; the second number represents the threads per inch (16 in this example, and the final number is the body length of the bolt or screw (in this example 2 inches long).

The guides and ruler furnished below are designed to help you select the appropriate hardware and tools.

0 |

| |

1/4 | Nut, 1/2” | |

1/2 | Inside | |

Diameter | ||

3/4 | ||

| ||

1 |

| |

1/4 |

| |

1/2 |

| |

3/4 | Screw, 1/2 x 2 | |

2 | Body | |

| ||

1/4 | Diameter | |

| ||

1/2 | Body | |

Length | ||

3/4 | ||

| ||

3 |

| |

1/4 |

| |

1/2 |

| |

3/4 |

| |

4 |

|

Torque Specification Chart

FOR STANDARD MACHINE HARDWARE (Tolerance ± 20%)

| Hardware |

| No |

|

|

|

|

|

|

| ||

| Marks |

|

|

|

|

|

|

| ||||

| Grade | SAE Grade 2 | SAE Grade 5 | SAE Grade 8 | ||||||||

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| Size Of | in/lbs |

|

| in/lbs |

|

| in/lbs |

|

|

| |

| Hardware | ft/lbs |

| Nm. | ft/lbs | Nm. | ft/lbs |

| Nm. | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

| 19 |

| 2.1 | 30 | 3.4 |

| 41 | 4.6 |

| |||

| 20 |

| 2.3 | 31 | 3.5 |

| 43 | 4.9 |

| |||

| 27 |

| 3.1 | 43 | 4.9 |

| 60 | 6.8 |

| |||

| 31 |

| 3.5 | 49 | 5.5 |

| 68 |

| 7.7 |

| ||

| 66 |

| 7.6 | 8 | 10.9 |

| 12 | 16.3 |

| |||

| 76 |

| 8.6 | 10 | 13.6 |

| 14 | 19.0 |

| |||

|

|

| 15.0 | 17 | 23.1 |

| 25 | 34.0 |

| |||

| 11 |

|

|

| ||||||||

| 12 |

| 16.3 | 19 | 25.8 |

| 27 | 34.0 |

| |||

| 20 |

| 27.2 | 30 | 40.8 |

| 45 | 61.2 |

| |||

| 23 |

| 31.3 | 35 | 47.6 |

| 50 | 68.0 |

| |||

| 30 |

| 40.8 | 50 | 68.0 |

| 70 | 95.2 |

| |||

| 35 |

| 47.6 | 55 | 74.8 |

| 80 | 108.8 |

| |||

| 50 |

| 68.0 | 75 | 102.0 |

| 110 | 149.6 |

| |||

| 55 |

| 74.8 | 90 | 122.4 |

| 120 | 163.2 |

| |||

| 65 |

| 88.4 | 110 | 149.6 |

| 150 | 204.0 |

| |||

| 75 |

| 102.0 | 120 | 163.2 |

| 170 | 231.2 |

| |||

| 90 |

| 122.4 | 150 | 204.0 |

| 220 | 299.2 |

| |||

| 100 |

| 136 | 180 | 244.8 |

| 240 | 326.4 |

| |||

| 160 |

| 217.6 | 260 | 353.6 |

| 386 | 525.0 |

| |||

| 180 |

| 244.8 | 300 | 408.0 |

| 420 | 571.2 |

| |||

| 140 |

| 190.4 | 400 | 544.0 |

| 600 | 816.0 |

| |||

| 155 |

| 210.8 | 440 | 598.4 |

| 660 | 897.6 |

| |||

| 220 |

| 299.2 | 580 | 788.8 |

| 900 | 1,244.0 |

| |||

| 240 |

| 326.4 | 640 | 870.4 |

| 1,000 | 1,360.0 |

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTES

1.These torque values are to be used for all hardware excluding: locknuts,

2.Recommended seating torque values for locknuts:

a.for prevailing torque locknuts - use 65% of grade 5 torques.

b.for flange whizlock nuts and screws - use 135% of grade 5 torques.

3.Unless otherwise noted on assembly drawings, all torque values must meet this specification.

Wrench & Fastener Size Guide

|

|

| 7/16 | 1/2 | |

|

| 3/8 | DIA. | ||

1/4 | 5/16 | DIA. | |||

| |||||

1/4” Bolt or Nut | 5/16” Bolt or Nut | 3/8” Bolt or Nut | 7/16” Bolt or Nut | 1/2” Bolt or Nut | |

Wrench | |||||

|

|

| Wrench |

|