Section 4 - REPAIR & ADJUSTMENTS

WARNING

DO NOT attempt any adjustments, maintenance, service, or repairs, with engine running. Stop auger. Stop engine. Remove key. Disconnect spark plug wire and secure wire away from spark plug. Before tilting machine, drain all the fuel from fuel tank. Allow engine to run, outdoors where fumes can be safely dissipated, until all fuel is removed from carburetor.

4.1.4.WHEEL DRIVE BELT REPLACEMENT Inspect belt frequently for signs of excessive wear. Visually check engine drive belt for cracking, fraying, severed or exposed belt strands.

1. Remove belt cover. See Figure 4.2.

2. Remove discharge chute.

3. Unhook both idler springs.

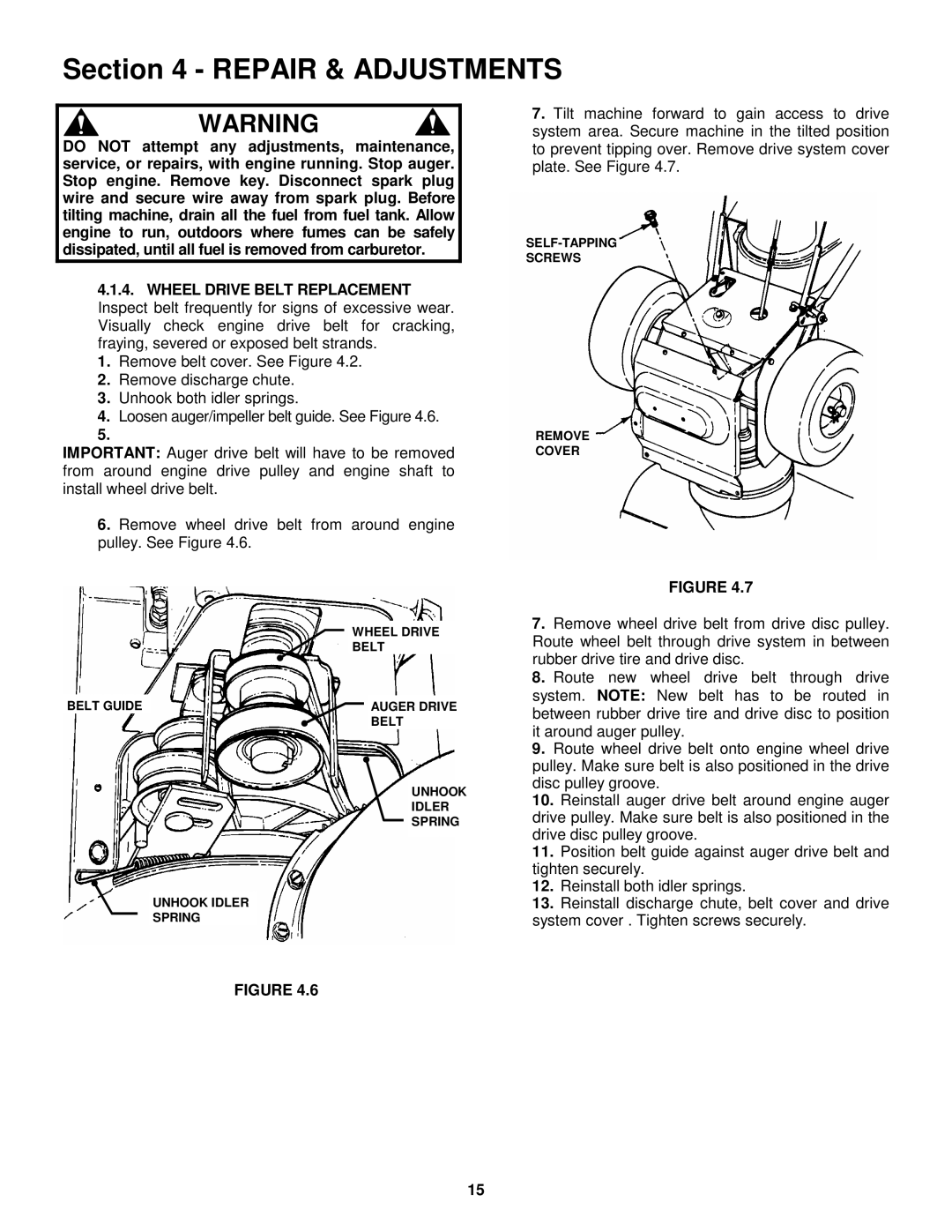

4. Loosen auger/impeller belt guide. See Figure 4.6.

5.

IMPORTANT: Auger drive belt will have to be removed from around engine drive pulley and engine shaft to install wheel drive belt.

6.Remove wheel drive belt from around engine pulley. See Figure 4.6.

WHEEL DRIVE

BELT

BELT GUIDE | AUGER DRIVE |

| BELT |

UNHOOK

IDLER

SPRING

UNHOOK IDLER

SPRING

7.Tilt machine forward to gain access to drive system area. Secure machine in the tilted position to prevent tipping over. Remove drive system cover plate. See Figure 4.7.

SCREWS

REMOVE

COVER

FIGURE 4.7

7.Remove wheel drive belt from drive disc pulley. Route wheel belt through drive system in between rubber drive tire and drive disc.

8.Route new wheel drive belt through drive system. NOTE: New belt has to be routed in between rubber drive tire and drive disc to position it around auger pulley.

9.Route wheel drive belt onto engine wheel drive pulley. Make sure belt is also positioned in the drive disc pulley groove.

10.Reinstall auger drive belt around engine auger drive pulley. Make sure belt is also positioned in the drive disc pulley groove.

11.Position belt guide against auger drive belt and tighten securely.

12.Reinstall both idler springs.

13.Reinstall discharge chute, belt cover and drive system cover . Tighten screws securely.

FIGURE 4.6

15