Section 2 - OPERATING INSTRUCTIONS

2.2STARTING, OPERATION & STOPPING (ELECTRIC START MODELS)

(Go to Page 7 for Recoil Start Models) (Continue From Previous Page)

WARNING

Objects can be thrown by the snow thrower while it is in operation. Thrown objects could cause serious injury to the operator or bystanders. Always wear safety goggles or other suitable eye protection. Keep people and pets away from area.

2.2.8. ENGAGING AUGER

1.Pull auger/impeller control lever against handle to engage auger/impeller. Refer to Figure 2.6.

2.2.9. ENGAGING WHEEL DRIVE

1.Move wheel drive control lever against handle to engage wheel drive. Ground speed can be adjusted while the machine is moving by changing position of the ground speed control. Machine has six forward speeds and one reverse. Refer to Figure 2.5.

WARNING

Release auger/impeller clutch control and make sure auger/impeller has STOPPED before rotating discharge chute, or adjusting deflector. DO NOT place hands near auger/impeller while engine is running.

2.2.10.DISCHARGE CHUTE and DEFLECTOR ADJUSTMENT

1.Release auger/impeller control and wheel drive control levers to allow auger/impeller and ground speed to come to a complete stop.

2.Position the deflector to the desired location using deflector handle located on control panel. Rotate deflector handle counter clockwise to unlock. Push handle to raise or pull handle to lower the deflector. Rotate deflector handle clockwise to lock into position.

3.Rotate chute crank to position discharge chute in desired direction. Refer to Figure 2.5.

2.2.11. STOPPING - ENGINE, AUGER & WHEEL DRIVE

Stop the auger/impeller and wheel drive by releasing the auger/impeller and wheel drive control levers. Stop the engine by moving the engine speed control to the stop position or removing the key from the switch. Always remove key from key switch before leaving machine unattended. Refer to Figure 2.7.

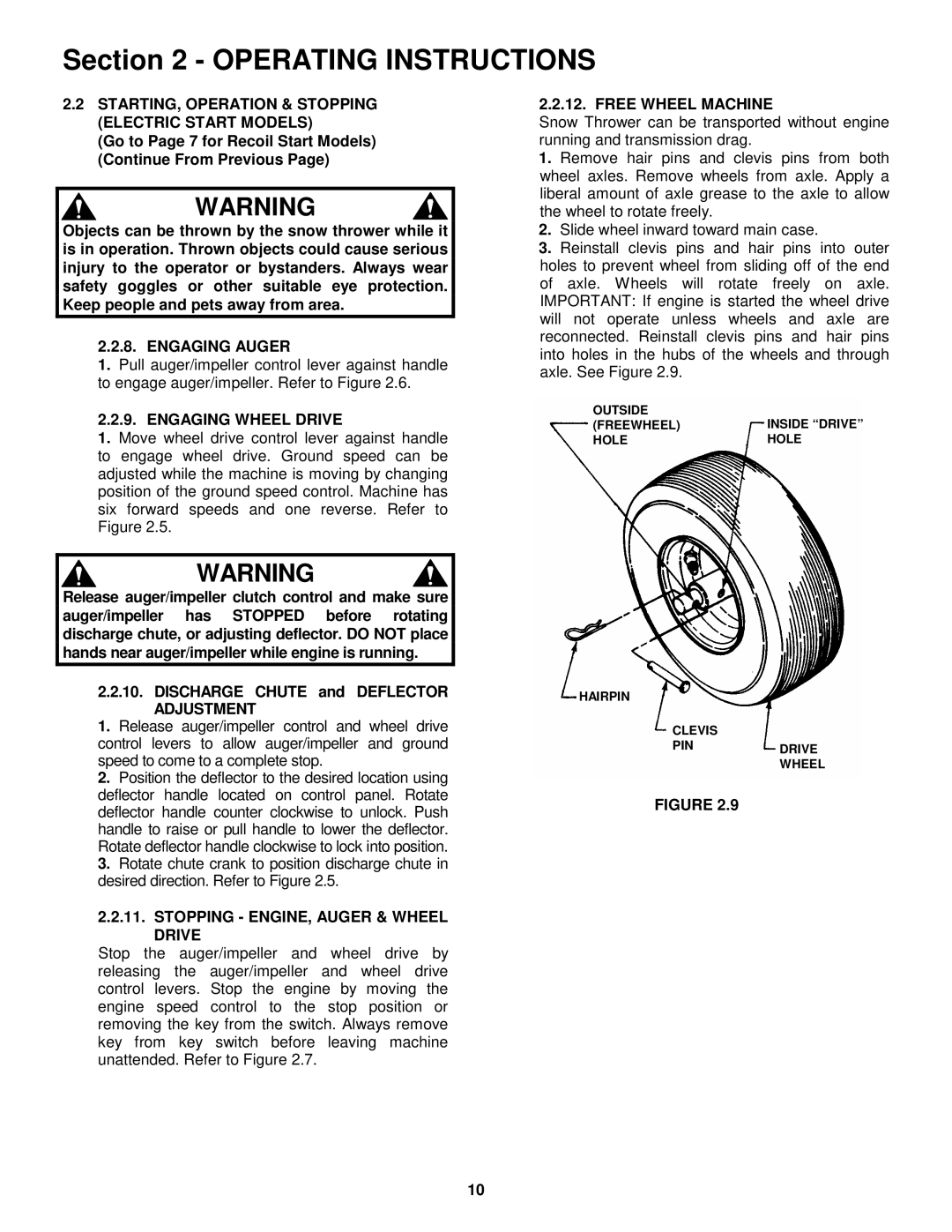

2.2.12. FREE WHEEL MACHINE

Snow Thrower can be transported without engine running and transmission drag.

1.Remove hair pins and clevis pins from both wheel axles. Remove wheels from axle. Apply a liberal amount of axle grease to the axle to allow the wheel to rotate freely.

2.Slide wheel inward toward main case.

3.Reinstall clevis pins and hair pins into outer holes to prevent wheel from sliding off of the end of axle. Wheels will rotate freely on axle. IMPORTANT: If engine is started the wheel drive will not operate unless wheels and axle are reconnected. Reinstall clevis pins and hair pins into holes in the hubs of the wheels and through axle. See Figure 2.9.

OUTSIDE | INSIDE “DRIVE” |

(FREEWHEEL) | |

HOLE | HOLE |

HAIRPIN

CLEVIS

PINDRIVE

WHEEL

FIGURE 2.9

10