Section 2 - OPERATING INSTRUCTIONS

2.1PRE-START CHECK LIST

Make the following checks and perform the service required before each

2.1.1.Check engine oil and add oil as needed to bring level up to the FULL mark. Refer to engine owner’s manual for oil specifications

2.1.2.Check guards, chutes, deflectors and covers to make sure all are in place and securely tightened.

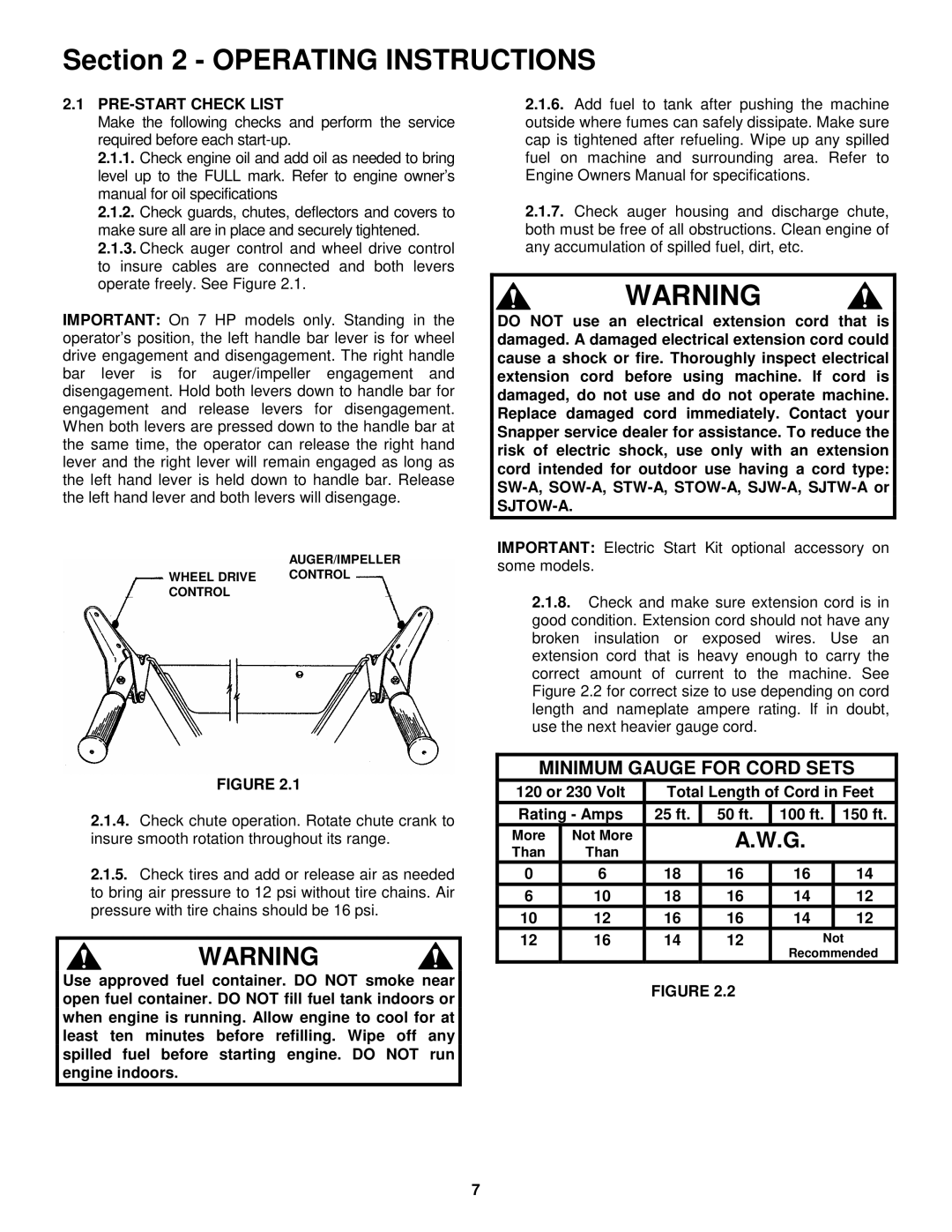

2.1.3.Check auger control and wheel drive control to insure cables are connected and both levers operate freely. See Figure 2.1.

IMPORTANT: On 7 HP models only. Standing in the operator’s position, the left handle bar lever is for wheel drive engagement and disengagement. The right handle bar lever is for auger/impeller engagement and disengagement. Hold both levers down to handle bar for engagement and release levers for disengagement. When both levers are pressed down to the handle bar at the same time, the operator can release the right hand lever and the right lever will remain engaged as long as the left hand lever is held down to handle bar. Release the left hand lever and both levers will disengage.

AUGER/IMPELLER

WHEEL DRIVE CONTROL

CONTROL

FIGURE 2.1

2.1.4.Check chute operation. Rotate chute crank to insure smooth rotation throughout its range.

2.1.5.Check tires and add or release air as needed to bring air pressure to 12 psi without tire chains. Air pressure with tire chains should be 16 psi.

WARNING

Use approved fuel container. DO NOT smoke near open fuel container. DO NOT fill fuel tank indoors or when engine is running. Allow engine to cool for at least ten minutes before refilling. Wipe off any spilled fuel before starting engine. DO NOT run engine indoors.

2.1.6.Add fuel to tank after pushing the machine outside where fumes can safely dissipate. Make sure cap is tightened after refueling. Wipe up any spilled fuel on machine and surrounding area. Refer to Engine Owners Manual for specifications.

2.1.7.Check auger housing and discharge chute, both must be free of all obstructions. Clean engine of any accumulation of spilled fuel, dirt, etc.

WARNING

DO NOT use an electrical extension cord that is damaged. A damaged electrical extension cord could cause a shock or fire. Thoroughly inspect electrical extension cord before using machine. If cord is damaged, do not use and do not operate machine. Replace damaged cord immediately. Contact your Snapper service dealer for assistance. To reduce the risk of electric shock, use only with an extension cord intended for outdoor use having a cord type:

IMPORTANT: Electric Start Kit optional accessory on some models.

2.1.8.Check and make sure extension cord is in good condition. Extension cord should not have any broken insulation or exposed wires. Use an extension cord that is heavy enough to carry the correct amount of current to the machine. See Figure 2.2 for correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gauge cord.

MINIMUM GAUGE FOR CORD SETS

120 or 230 Volt | Total Length of Cord in Feet | ||||

Rating - Amps | 25 ft. | 50 ft. | 100 ft. | 150 ft. | |

More | Not More |

| A.W.G. |

| |

Than | Than |

|

| ||

|

|

|

| ||

0 | 6 | 18 | 16 | 16 | 14 |

6 | 10 | 18 | 16 | 14 | 12 |

10 | 12 | 16 | 16 | 14 | 12 |

12 | 16 | 14 | 12 | Not | |

|

|

|

| Recommended | |

|

| FIGURE 2.2 |

|

| |

7