SECTION 2 - SET-UP INSTRUCTIONS FOR SNAPPER 73” FINISHING MOWER

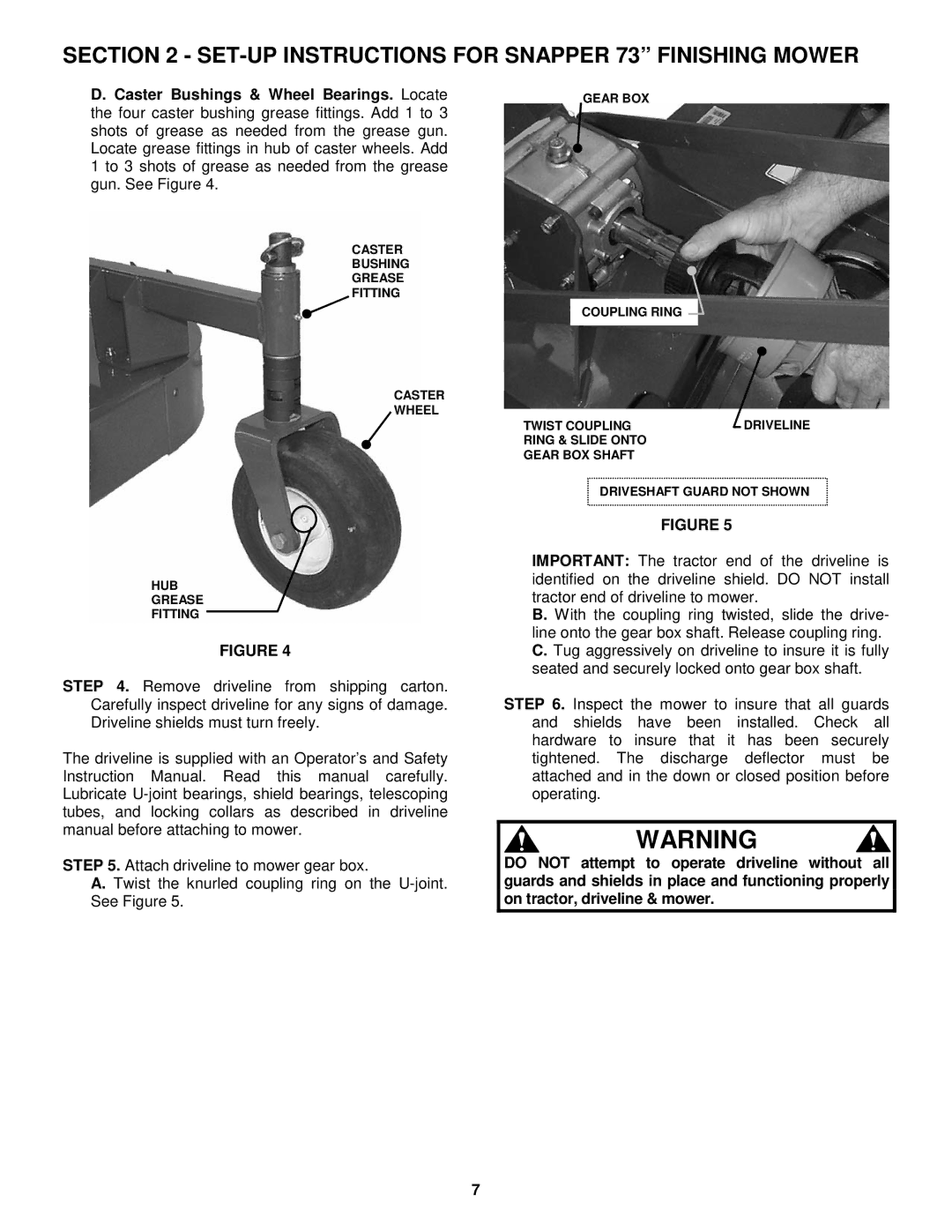

D. Caster Bushings & Wheel Bearings. Locate the four caster bushing grease fittings. Add 1 to 3 shots of grease as needed from the grease gun. Locate grease fittings in hub of caster wheels. Add 1 to 3 shots of grease as needed from the grease gun. See Figure 4.

CASTER

BUSHING

GREASE

FITTING

CASTER

WHEEL

HUB

GREASE

FITTING

FIGURE 4

STEP 4. Remove driveline from shipping carton. Carefully inspect driveline for any signs of damage. Driveline shields must turn freely.

The driveline is supplied with an Operator’s and Safety Instruction Manual. Read this manual carefully. Lubricate

STEP 5. Attach driveline to mower gear box.

A. Twist the knurled coupling ring on the

GEAR BOX

COUPLING RING

TWIST COUPLING | DRIVELINE |

RING & SLIDE ONTO |

|

GEAR BOX SHAFT |

|

DRIVESHAFT GUARD NOT SHOWN

FIGURE 5

IMPORTANT: The tractor end of the driveline is identified on the driveline shield. DO NOT install tractor end of driveline to mower.

B. With the coupling ring twisted, slide the drive- line onto the gear box shaft. Release coupling ring. C. Tug aggressively on driveline to insure it is fully seated and securely locked onto gear box shaft.

STEP 6. Inspect the mower to insure that all guards and shields have been installed. Check all hardware to insure that it has been securely tightened. The discharge deflector must be attached and in the down or closed position before operating.

WARNING

DO NOT attempt to operate driveline without all guards and shields in place and functioning properly on tractor, driveline & mower.

7