NZM19481KWV specifications

The Snapper NZM19481KWV is a robust and versatile ride-on lawn mower that offers exceptional performance and efficiency for various residential and commercial landscaping needs. Engineered for precision and durability, this model is a popular choice among lawn care enthusiasts looking to maintain their outdoor space with ease.One of the standout features of the Snapper NZM19481KWV is its powerful engine. Equipped with a reliable Briggs & Stratton engine, the mower delivers ample power to tackle even the toughest grass conditions. The engine's high torque ensures that the mower can handle hilly terrains and thick grass without compromising performance. Additionally, the engine meets stringent emissions standards, making it an environmentally friendly choice.

The cutting deck on the NZM19481KWV is another highlight. It boasts a 48-inch fabricated cutting deck, which provides a wide cutting path for faster mowing. The deck's design ensures superior airflow, resulting in a finer and more consistent cut. Users can easily adjust the cutting height with a simple lever, allowing for a customized mowing experience suited to various grass types and conditions.

This mower employs innovative technologies that add to its appeal. The AutoShift transmission allows for smooth and effortless gear changes, enabling users to maintain optimal speed regardless of terrain. Coupled with responsive steering, the Snapper NZM19481KWV provides excellent maneuverability, making it ideal for navigating tight spaces and complex landscapes.

Comfort is also a priority with the Snapper NZM19481KWV. The mower features an ergonomic seat with ample cushioning and adjustable armrests, ensuring a comfortable mowing experience even during extended use. The user-friendly controls are intuitively placed, allowing for easy operation without taking your focus off the mowing task at hand.

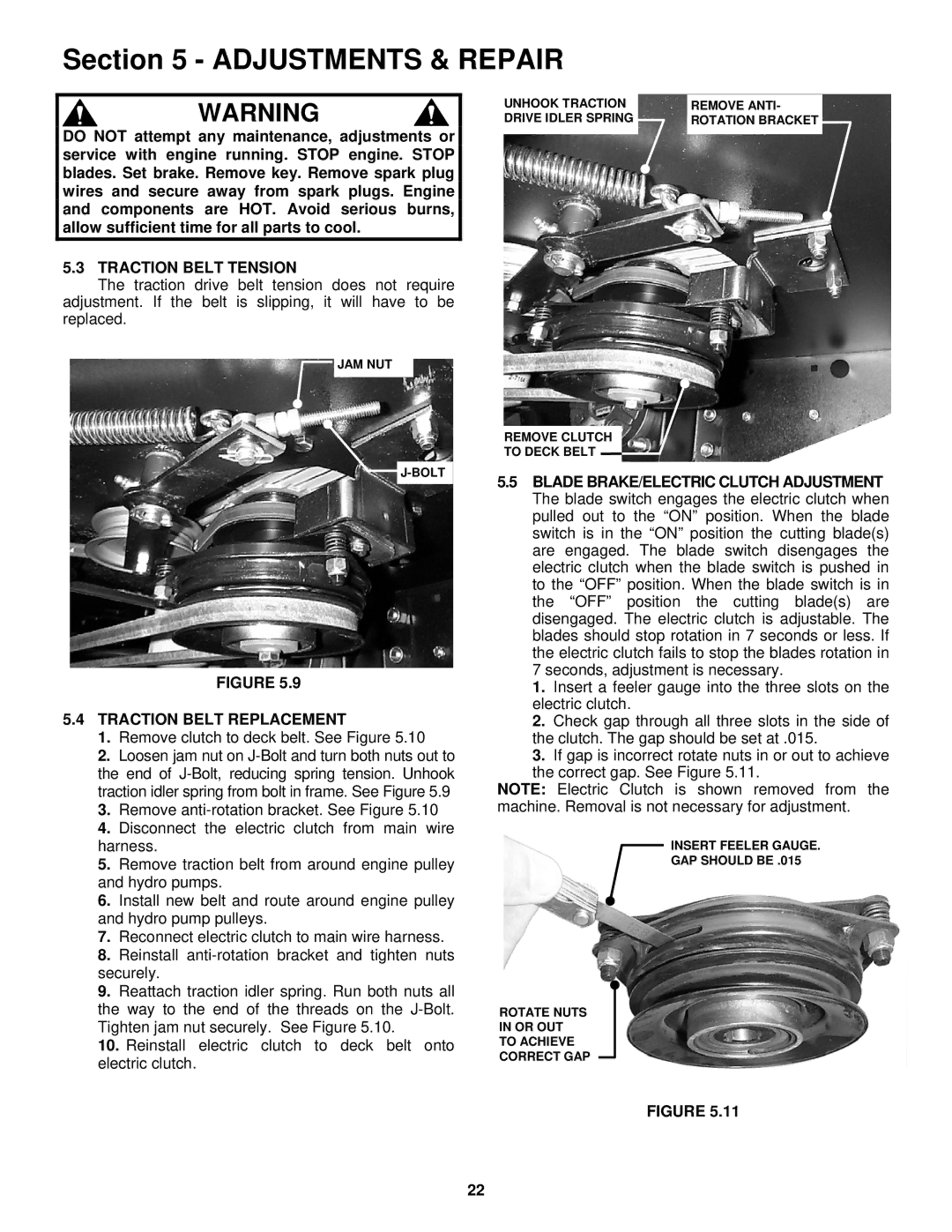

In terms of maintenance, the Snapper NZM19481KWV is designed for convenience. Its accessible engine and easy-to-remove cutting deck simplify routine tasks, such as oil changes and blade sharpening. The molded fender and deck prevent rust, prolonging the lifespan of the mower.

Overall, the Snapper NZM19481KWV combines performance, technology, and comfort, making it a worthwhile investment for anyone seeking to achieve a pristine lawn. Whether for home use or commercial landscaping, this ride-on mower stands out with its comprehensive features designed to deliver exceptional results.