SECTION 3 - OPERATING INSTRUCTIONS

3.7 HANDLE HEIGHT ADJUSTMENT

(Continued from previous page)

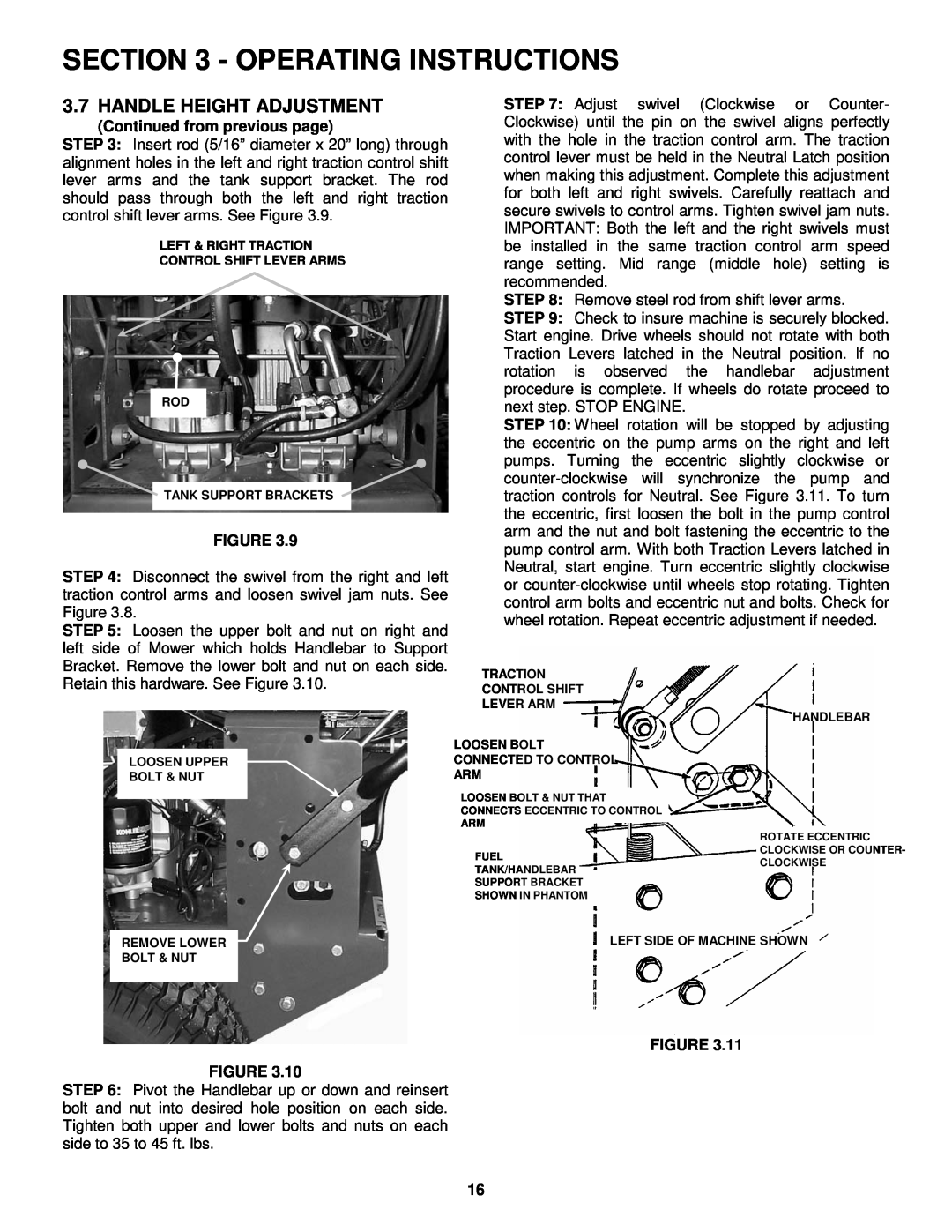

STEP 3: Insert rod (5/16” diameter x 20” long) through alignment holes in the left and right traction control shift lever arms and the tank support bracket. The rod should pass through both the left and right traction control shift lever arms. See Figure 3.9.

LEFT & RIGHT TRACTION

CONTROL SHIFT LEVER ARMS

ROD

TANK SUPPORT BRACKETS

FIGURE 3.9

STEP 4: Disconnect the swivel from the right and left traction control arms and loosen swivel jam nuts. See Figure 3.8.

STEP 5: Loosen the upper bolt and nut on right and left side of Mower which holds Handlebar to Support Bracket. Remove the lower bolt and nut on each side. Retain this hardware. See Figure 3.10.

STEP 7: Adjust swivel (Clockwise or Counter- Clockwise) until the pin on the swivel aligns perfectly with the hole in the traction control arm. The traction control lever must be held in the Neutral Latch position when making this adjustment. Complete this adjustment for both left and right swivels. Carefully reattach and secure swivels to control arms. Tighten swivel jam nuts. IMPORTANT: Both the left and the right swivels must be installed in the same traction control arm speed range setting. Mid range (middle hole) setting is recommended.

STEP 8: Remove steel rod from shift lever arms.

STEP 9: Check to insure machine is securely blocked. Start engine. Drive wheels should not rotate with both Traction Levers latched in the Neutral position. If no rotation is observed the handlebar adjustment procedure is complete. If wheels do rotate proceed to next step. STOP ENGINE.

STEP 10: Wheel rotation will be stopped by adjusting the eccentric on the pump arms on the right and left pumps. Turning the eccentric slightly clockwise or

TRACTION CONTROL SHIFT LEVER ARM

HANDLEBAR

LOOSEN UPPER BOLT & NUT

LOOSEN BOLT CONNECTED TO CONTROL ARM

LOOSEN BOLT & NUT THAT CONNECTS ECCENTRIC TO CONTROL ARM

FUEL

TANK/HANDLEBAR

SUPPORT BRACKET

SHOWN IN PHANTOM

ROTATE ECCENTRIC CLOCKWISE OR COUNTER- CLOCKWISE

REMOVE LOWER | LEFT SIDE OF MACHINE SHOWN |

BOLT & NUT |

|

|

|

FIGURE 3.11

FIGURE 3.10

STEP 6: Pivot the Handlebar up or down and reinsert bolt and nut into desired hole position on each side. Tighten both upper and lower bolts and nuts on each side to 35 to 45 ft. lbs.

16