STEP 8: Check the clearance between the clutch cable

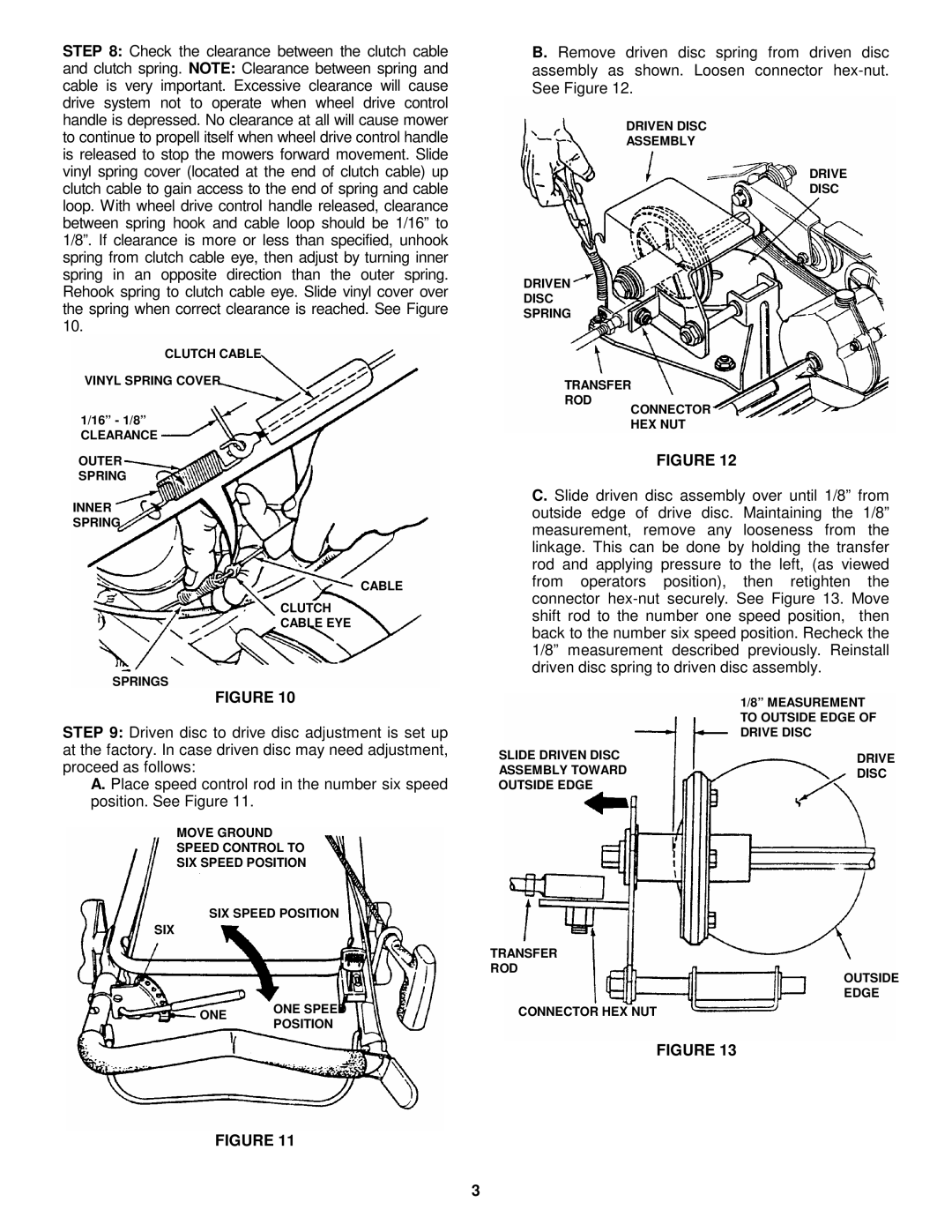

and clutch spring. NOTE: Clearance between spring and cable is very important. Excessive clearance will cause drive system not to operate when wheel drive control handle is depressed. No clearance at all will cause mower to continue to propell itself when wheel drive control handle is released to stop the mowers forward movement. Slide vinyl spring cover (located at the end of clutch cable) up clutch cable to gain access to the end of spring and cable loop. With wheel drive control handle released, clearance between spring hook and cable loop should be 1/16” to 1/8”. If clearance is more or less than specified, unhook spring from clutch cable eye, then adjust by turning inner spring in an opposite direction than the outer spring. Rehook spring to clutch cable eye. Slide vinyl cover over the spring when correct clearance is reached. See Figure 10.

CLUTCH CABLE

VINYL SPRING COVER

1/16” - 1/8”

CLEARANCE

OUTER

SPRING

INNER

SPRING

CABLE

CLUTCH

CABLE EYE

SPRINGS

FIGURE 10

STEP 9: Driven disc to drive disc adjustment is set up at the factory. In case driven disc may need adjustment, proceed as follows:

A. Place speed control rod in the number six speed position. See Figure 11.

MOVE GROUND

SPEED CONTROL TO

SIX SPEED POSITION

SIX SPEED POSITION

SIX

ONE | ONE SPEED | |

POSITION | ||

|

FIGURE 11

B. Remove driven disc spring from driven disc assembly as shown. Loosen connector

DRIVEN DISC

ASSEMBLY

DRIVE

DISC

DRIVEN

DISC

SPRING

TRANSFER

ROD

CONNECTOR

HEX NUT

FIGURE 12

C. Slide driven disc assembly over until 1/8” from outside edge of drive disc. Maintaining the 1/8” measurement, remove any looseness from the linkage. This can be done by holding the transfer rod and applying pressure to the left, (as viewed from operators position), then retighten the connector

| 1/8” MEASUREMENT |

| TO OUTSIDE EDGE OF |

| DRIVE DISC |

SLIDE DRIVEN DISC | DRIVE |

ASSEMBLY TOWARD | DISC |

OUTSIDE EDGE |

|

TRANSFER

ROD

OUTSIDE EDGE

CONNECTOR HEX NUT

FIGURE 13

3