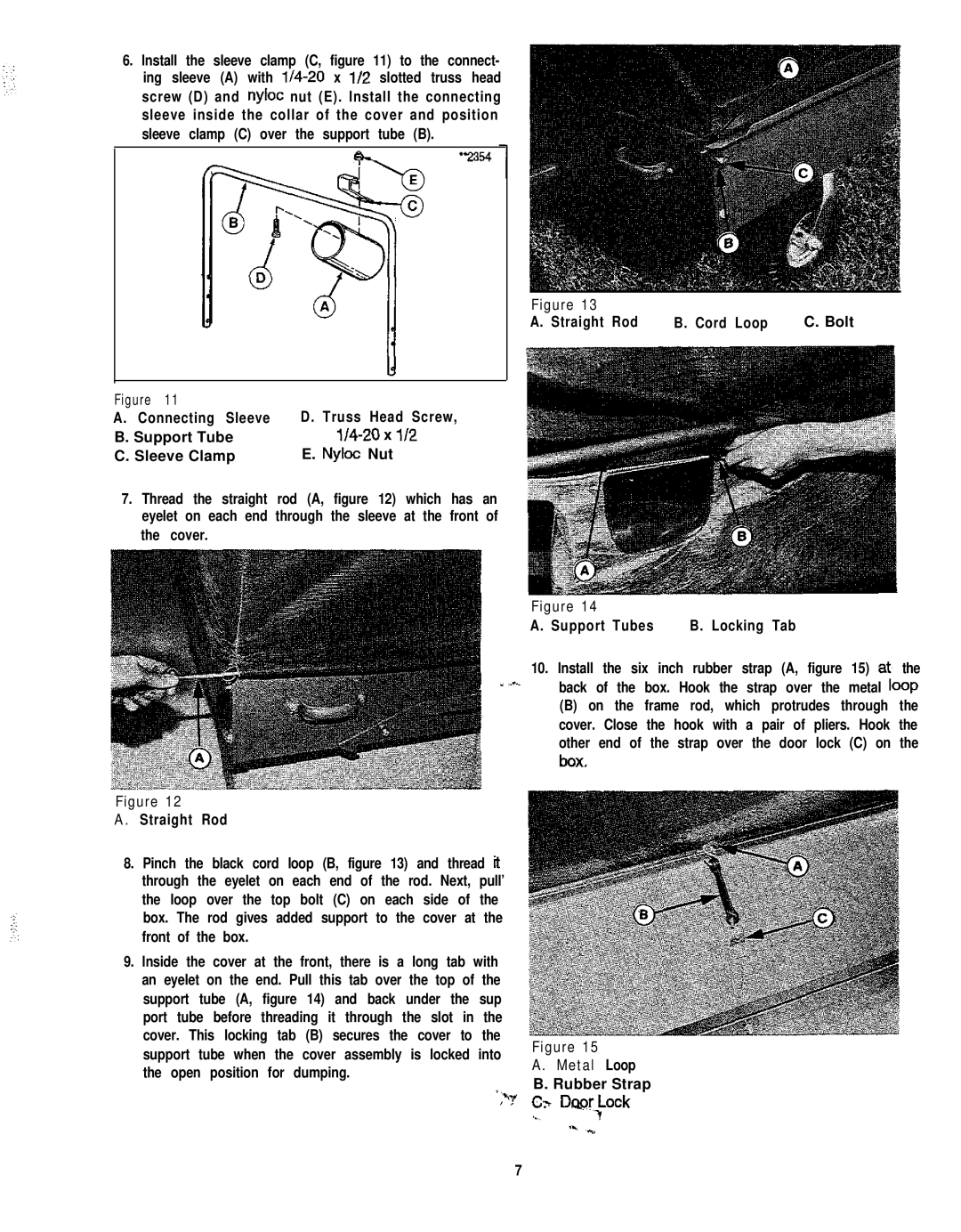

6.Install the sleeve clamp (C, figure 11) to the connect- ing sleeve (A) with

‘23!i4

Figure 11 | D. Truss | Head Screw, |

A. Connecting Sleeve | ||

B. Support Tube | ||

C. Sleeve Clamp | E. Nyloc | Nut |

7.Thread the straight rod (A, figure 12) which has an eyelet on each end through the sleeve at the front of the cover.

Figure 13

A. Straight Rod B. Cord Loop C. Bolt

. ..-

Figure 12

A. Straight Rod

8.Pinch the black cord loop (B, figure 13) and thread it through the eyelet on each end of the rod. Next, pull’ the loop over the top bolt (C) on each side of the box. The rod gives added support to the cover at the front of the box.

9.Inside the cover at the front, there is a long tab with an eyelet on the end. Pull this tab over the top of the support tube (A, figure 14) and back under the sup port tube before threading it through the slot in the cover. This locking tab (B) secures the cover to the support tube when the cover assembly is locked into the open position for dumping.

‘;y

Figure 14

A. Support Tubes B. Locking Tab

10.Install the six inch rubber strap (A, figure 15) at, the back of the box. Hook the strap over the metal loop

(B)on the frame rod, which protrudes through the cover. Close the hook with a pair of pliers. Hook the other end of the strap over the door lock (C) on the

bOX.

Figure 15

A. Metal Loop

B. Rubber Strap

C> Dc+ock

..,~

‘., ,_,

7