| 1.5PL |

• | Precision Multi-Line Laser |

| User Guide |

www.trimble.com

Introduction

Thank you for choosing the Spectra Precision® 1.5PL from the Trimble® family of precision products. This simple-to-use tool allows you to perform leveling or vertical plumb work. You can also use the laser outdoors for leveling and aligning applications (optional HR220 receiver required).

Before using the laser, be sure to read this operator’s manual carefully. Included in it is information about setting up, using, and maintaining the laser. Also included in this manual are CAUTIONS and Notes. Each of these words represents a level or danger or concern. A CAUTION indicates a hazard or unsafe practice that could result in minor injury or property damage. A Note indicates important information unrelated to safety.

Your comments and suggestions are welcome; please contact us at:

Trimble Spectra Precision Division 8261 State Route 235

Dayton, Ohio 45424 U.S.A.

Phone: (937) 245-5600

(800)538-7800 FAX: (937) 482-0030 Internet: www.trimble.com/spectra

– 2 –

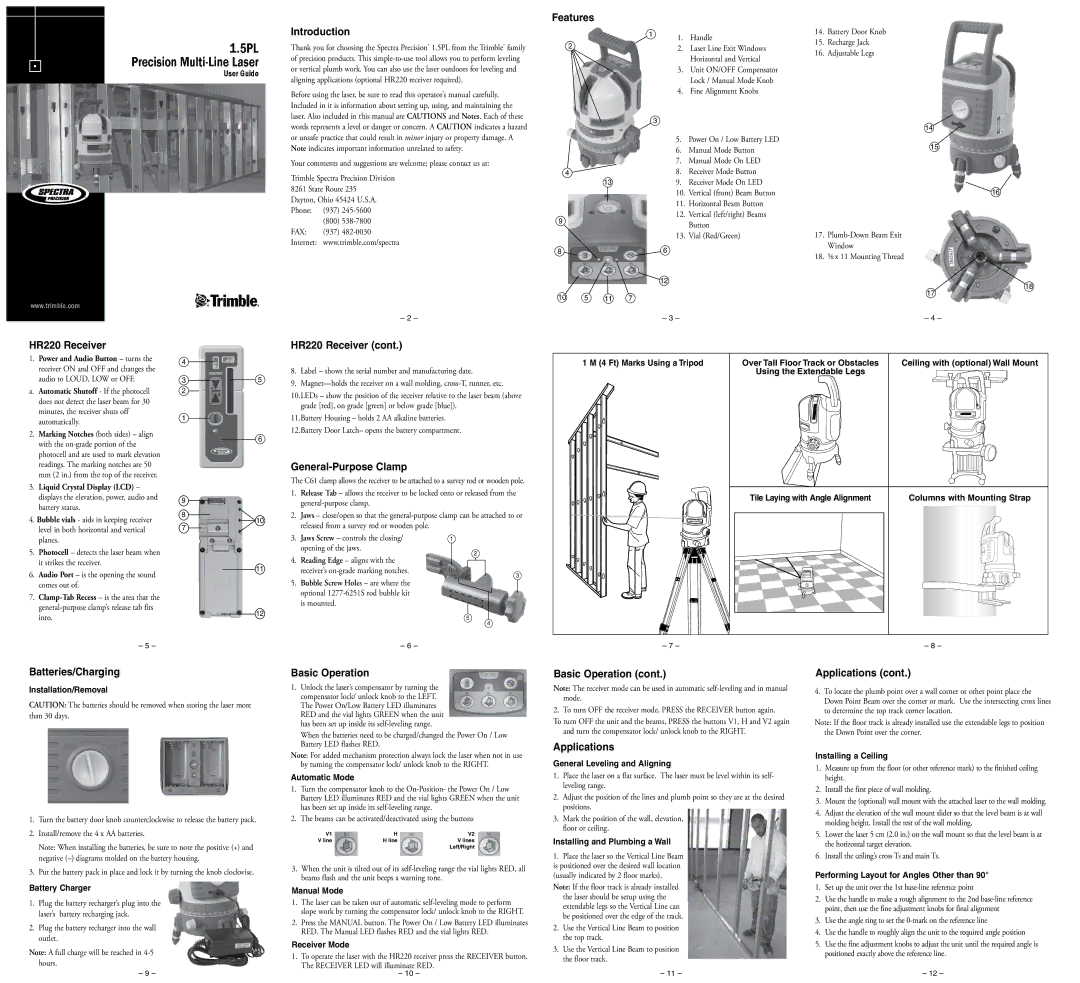

Features

| 1 | 1. | Handle | 14. | Battery Door Knob |

2 | | 15. | Recharge Jack |

| 2. | Laser Line Exit Windows |

| 16. | Adjustable Legs |

| | | Horizontal and Vertical |

| | | | |

3.Unit ON/OFF Compensator Lock / Manual Mode Knob

4.Fine Alignment Knobs

3  14

14

| | 5. | Power On / Low Battery LED | 15 |

| | 6. | Manual Mode Button |

| | |

| | 7. | Manual Mode On LED | |

4 | | 8. | Receiver Mode Button | |

13 | 9. | Receiver Mode On LED | |

| | 10. | Vertical (front) Beam Button | 16 |

| | 11. | Horizontal Beam Button | |

9 | | 12. | Vertical (left/right) Beams | |

| | Button | |

| | | 17. Plumb-Down Beam Exit |

| | 13. | Vial (Red/Green) |

8 | | 6 | | Window |

| | 18. 5/8 x 11 Mounting Thread |

| | | |

HR220 Receiver

1.Power and Audio Button – turns the receiver ON and OFF and changes the audio to LOUD, LOW or OFF.

a.Automatic Shutoff - If the photocell does not detect the laser beam for 30 minutes, the receiver shuts off automatically.

HR220 Receiver (cont.)

8.Label – shows the serial number and manufacturing date.

9.Magnet—holds the receiver on a wall molding, cross-T, runner, etc.

10.LEDs – show the position of the receiver relative to the laser beam (above grade [red], on grade [green] or below grade [blue]).

11.Battery Housing – holds 2 AA alkaline batteries.

1 M (4 Ft) Marks Using a Tripod | Over Tall Floor Track or Obstacles | Ceiling with (optional) Wall Mount |

| Using the Extendable Legs | |

Batteries/Charging

Installation/Removal

CAUTION: The batteries should be removed when storing the laser more than 30 days.

1.Turn the battery door knob counterclockwise to release the battery pack.

2.Install/remove the 4 x AA batteries.

Note: When installing the batteries, be sure to note the positive (+) and negative (–) diagrams molded on the battery housing.

3.Put the battery pack in place and lock it by turning the knob clockwise.

Battery Charger

1.Plug the battery recharger’s plug into the laser’s battery recharging jack.

2.Plug the battery recharger into the wall outlet.

Note: A full charge will be reached in 4-5 hours.

Basic Operation

1.Unlock the laser’s compensator by turning the compensator lock/ unlock knob to the LEFT. The Power On/Low Battery LED illuminates RED and the vial lights GREEN when the unit has been set up inside its self-leveling range.

When the batteries need to be charged/changed the Power On / Low Battery LED flashes RED.

Note: For added mechanism protection always lock the laser when not in use by turning the compensator lock/ unlock knob to the RIGHT.

Automatic Mode

1.Turn the compensator knob to the On-Position- the Power On / Low Battery LED illuminates RED and the vial lights GREEN when the unit has been set up inside its self-leveling range.

2.The beams can be activated/deactivated using the buttons

V1 | H | V2 |

V line | H line | V lines |

| | Left/Right |

3.When the unit is tilted out of its self-leveling range the vial lights RED, all beams flash and the unit beeps a warning tone.

Manual Mode

1.The laser can be taken out of automatic self-leveling mode to perform slope work by turning the compensator lock/ unlock knob to the RIGHT.

2.Press the MANUAL button. The Power On / Low Battery LED illuminates RED. The Manual LED flashes RED and the vial lights RED.

Receiver Mode

1.To operate the laser with the HR220 receiver press the RECEIVER button. The RECEIVER LED will illuminate RED.

Basic Operation (cont.)

Note: The receiver mode can be used in automatic self-leveling and in manual mode.

2. To turn OFF the receiver mode, PRESS the RECEIVER button again.

To turn OFF the unit and the beams, PRESS the buttons V1, H and V2 again and turn the compensator lock/ unlock knob to the RIGHT.

Applications

General Leveling and Aligning

1.Place the laser on a flat surface. The laser must be level within its self- leveling range.

2.Adjust the position of the lines and plumb point so they are at the desired positions.

3.Mark the position of the wall, elevation, floor or ceiling.

Installing and Plumbing a Wall

1.Place the laser so the Vertical Line Beam is positioned over the desired wall location (usually indicated by 2 floor marks).

Note: If the floor track is already installed the laser should be setup using the extendable legs so the Vertical Line can be positioned over the edge of the track.

2.Use the Vertical Line Beam to position the top track.

3.Use the Vertical Line Beam to position the floor track.

Applications (cont.)

4.To locate the plumb point over a wall corner or other point place the Down Point Beam over the corner or mark. Use the intersecting cross lines to determine the top track corner location.

Note: If the floor track is already installed use the extendable legs to position the Down Point over the corner.

Installing a Ceiling

1.Measure up from the floor (or other reference mark) to the finished ceiling height.

2.Install the first piece of wall molding.

3.Mount the (optional) wall mount with the attached laser to the wall molding.

4.Adjust the elevation of the wall mount slider so that the level beam is at wall molding height. Install the rest of the wall molding.

5.Lower the laser 5 cm (2.0 in.) on the wall mount so that the level beam is at the horizontal target elevation.

6.Install the ceiling’s cross Ts and main Ts.

Performing Layout for Angles Other than 90°

1.Set up the unit over the 1st base-line reference point

2.Use the handle to make a rough alignment to the 2nd base-line reference point, then use the fine adjustment knobs for final alignment

3.Use the angle ring to set the 0-mark on the reference line

4.Use the handle to roughly align the unit to the required angle position

5.Use the fine adjustment knobs to adjust the unit until the required angle is positioned exactly above the reference line.