10 | GAS INSTRUCTIONS |

|

|

CAUTION: Place dust cap on cylinder valve outlet whenever the cylinder is not in use. Only install the type of dust cap on the cylinder valve outlet that is provided with the cylinder valve. Other types of caps or plugs may result in leakage of propane.

•Do not use a damaged LP cylinder. Dented or rusty LP cylinders or LP cylinders with a damaged valve may be hazardous and should be replaced with a new one immediately.

Liquid Propane (LP) Cylinder(s)

•The joint where the hose connects to the LP cylinder must be leak tested each time the LP cylinder is reconnected. For example, test each time the LP cylinder is refi lled.

•Be sure the regulator is mounted with the small vent hole pointed downward so that it will not collect water. This vent should be free of dirt, grease, bugs etc.

•The gas connections supplied with your Weber® gas barbecue have been designed and tested to meet 100% CSA and ANSI requirements.

WARNING: Replacement LP tanks must match the regulator connection supplied with this barbecue.

Liquid Propane Cylinder requirements

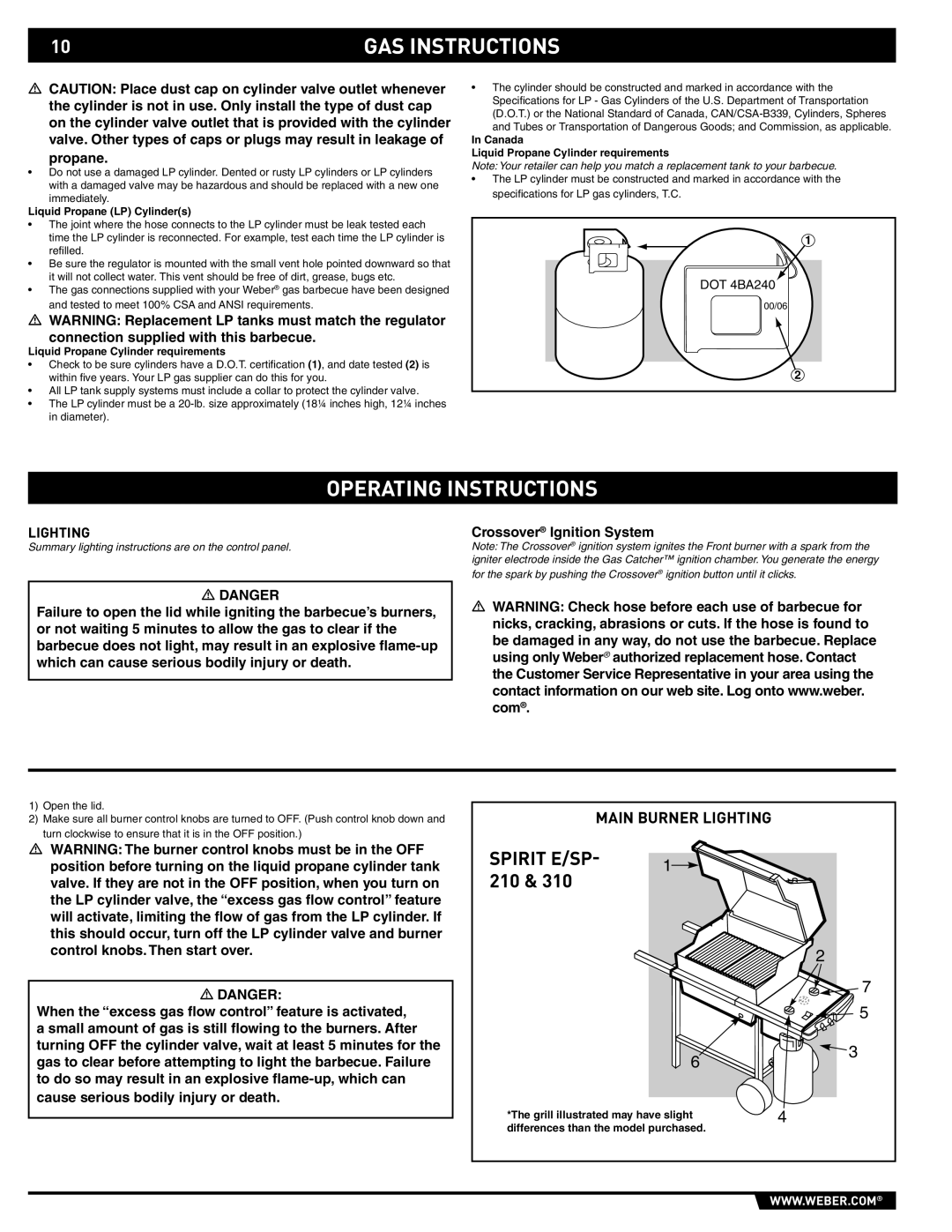

•Check to be sure cylinders have a D.O.T. certification (1), and date tested (2) is within fi ve years. Your LP gas supplier can do this for you.

•All LP tank supply systems must include a collar to protect the cylinder valve.

•The LP cylinder must be a

•The cylinder should be constructed and marked in accordance with the Specifi cations for LP - Gas Cylinders of the U.S. Department of Transportation (D.O.T.) or the National Standard of Canada,

and Tubes or Transportation of Dangerous Goods; and Commission, as applicable.

In Canada

Liquid Propane Cylinder requirements

Note: Your retailer can help you match a replacement tank to your barbecue.

•The LP cylinder must be constructed and marked in accordance with the specifi cations for LP gas cylinders, T.C.

1

DOT 4BA240

00/06

2

OPERATING INSTRUCTIONS

LIGHTING

Summary lighting instructions are on the control panel.

Crossover® Ignition System

Note: The Crossover® ignition system ignites the Front burner with a spark from the igniter electrode inside the Gas Catcher™ ignition chamber. You generate the energy for the spark by pushing the Crossover® ignition button until it clicks.

DANGER

Failure to open the lid while igniting the barbecue’s burners, or not waiting 5 minutes to allow the gas to clear if the barbecue does not light, may result in an explosive

WARNING: Check hose before each use of barbecue for nicks, cracking, abrasions or cuts. If the hose is found to be damaged in any way, do not use the barbecue. Replace using only Weber® authorized replacement hose. Contact the Customer Service Representative in your area using the contact information on our web site. Log onto www.weber. com®.

1)Open the lid.

2)Make sure all burner control knobs are turned to OFF. (Push control knob down and turn clockwise to ensure that it is in the OFF position.)

WARNING: The burner control knobs must be in the OFF position before turning on the liquid propane cylinder tank valve. If they are not in the OFF position, when you turn on the LP cylinder valve, the “excess gas flow control” feature will activate, limiting the flow of gas from the LP cylinder. If this should occur, turn off the LP cylinder valve and burner control knobs. Then start over.

DANGER:

When the “excess gas flow control” feature is activated, a small amount of gas is still flowing to the burners. After turning OFF the cylinder valve, wait at least 5 minutes for the gas to clear before attempting to light the barbecue. Failure to do so may result in an explosive

MAIN BURNER LIGHTING

SPIRIT E/SP- | 1 |

|

210 & 310 |

| |

|

| |

|

| 2 |

|

| 7 |

|

| 5 |

| 6 | 3 |

|

| |

*The grill illustrated may have slight | 4 | |

differences than the model purchased. |

| |

WWW.WEBER.COM®