Maintenance

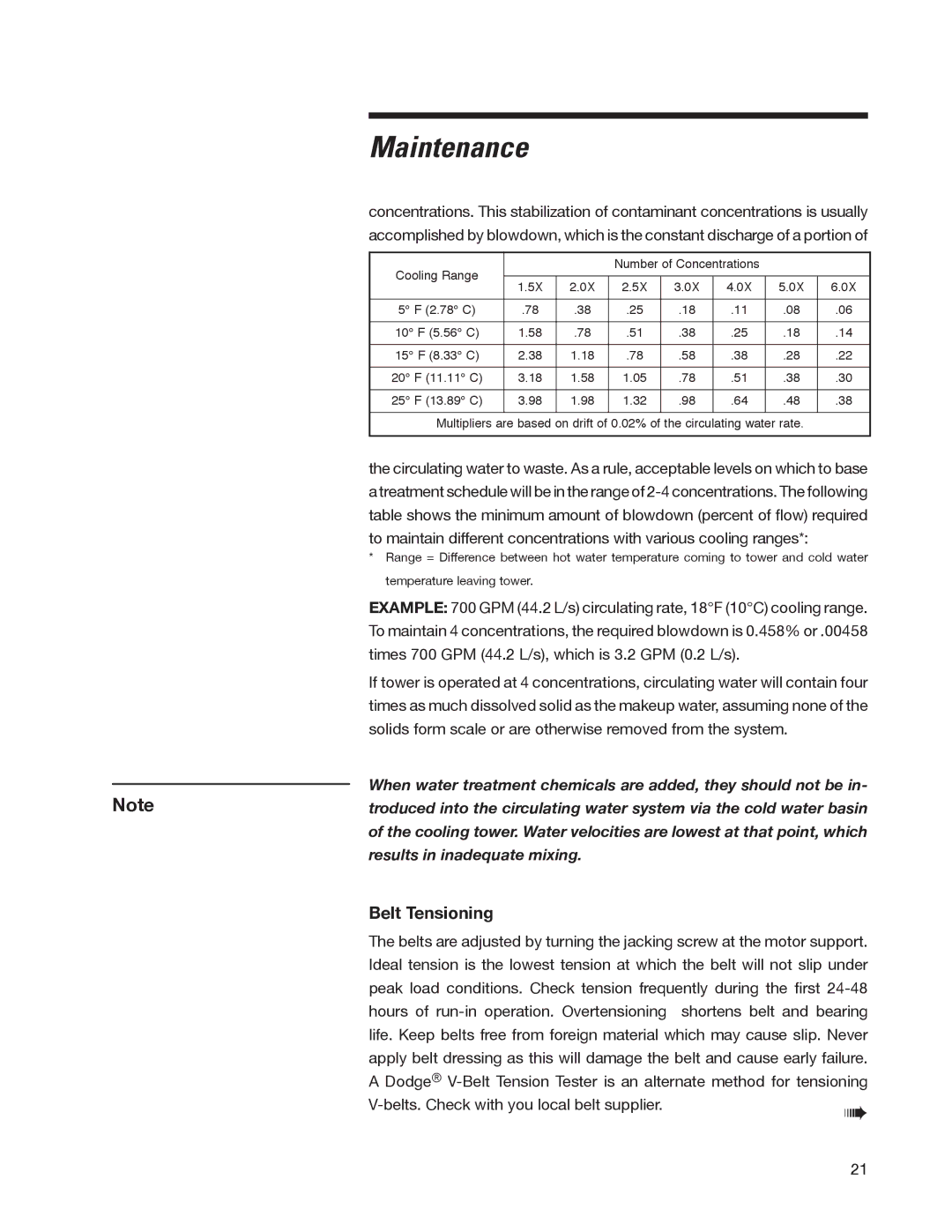

concentrations. This stabilization of contaminant concentrations is usually accomplished by blowdown, which is the constant discharge of a portion of

Cooling Range |

|

| Number of Concentrations |

|

| |||

|

|

|

|

|

|

| ||

1.5X | 2.0X | 2.5X | 3.0X | 4.0X | 5.0X | 6.0X | ||

| ||||||||

|

|

|

|

|

|

|

| |

5° F (2.78° C) | .78 | .38 | .25 | .18 | .11 | .08 | .06 | |

10° F (5.56° C) | 1.58 | .78 | .51 | .38 | .25 | .18 | .14 | |

|

|

|

|

|

|

|

| |

15° F (8.33° C) | 2.38 | 1.18 | .78 | .58 | .38 | .28 | .22 | |

20° F (11.11° C) | 3.18 | 1.58 | 1.05 | .78 | .51 | .38 | .30 | |

|

|

|

|

|

|

|

| |

25° F (13.89° C) | 3.98 | 1.98 | 1.32 | .98 | .64 | .48 | .38 | |

Multipliers are based on drift of 0.02% of the circulating water rate.

the circulating water to waste. As a rule, acceptable levels on which to base a treatment schedule will be in the range of

*Range = Difference between hot water temperature coming to tower and cold water temperature leaving tower.

EXAMPLE: 700 GPM (44.2 L/s) circulating rate, 18°F (10°C) cooling range. To maintain 4 concentrations, the required blowdown is 0.458% or .00458 times 700 GPM (44.2 L/s), which is 3.2 GPM (0.2 L/s).

If tower is operated at 4 concentrations, circulating water will contain four times as much dissolved solid as the makeup water, assuming none of the solids form scale or are otherwise removed from the system.

When water treatment chemicals are added, they should not be in-

Notetroduced into the circulating water system via the cold water basin of the cooling tower. Water velocities are lowest at that point, which results in inadequate mixing.

Belt Tensioning

The belts are adjusted by turning the jacking screw at the motor support. Ideal tension is the lowest tension at which the belt will not slip under peak load conditions. Check tension frequently during the first

➠ | |

|

21