F400 specifications

The SPX Cooling Technologies F400 is an advanced cooling tower renowned for its robust design, efficiency, and versatility in industrial applications. Engineered with cutting-edge technologies, the F400 addresses the demanding thermal management needs of various sectors, including power generation, oil and gas, and manufacturing.One of the standout features of the F400 is its modular design, allowing for seamless scalability. This design enables businesses to adapt their cooling solutions to fluctuating demand without compromising on performance. The ability to integrate multiple units into a singular system provides flexibility in addressing specific cooling needs while maintaining operational efficiency.

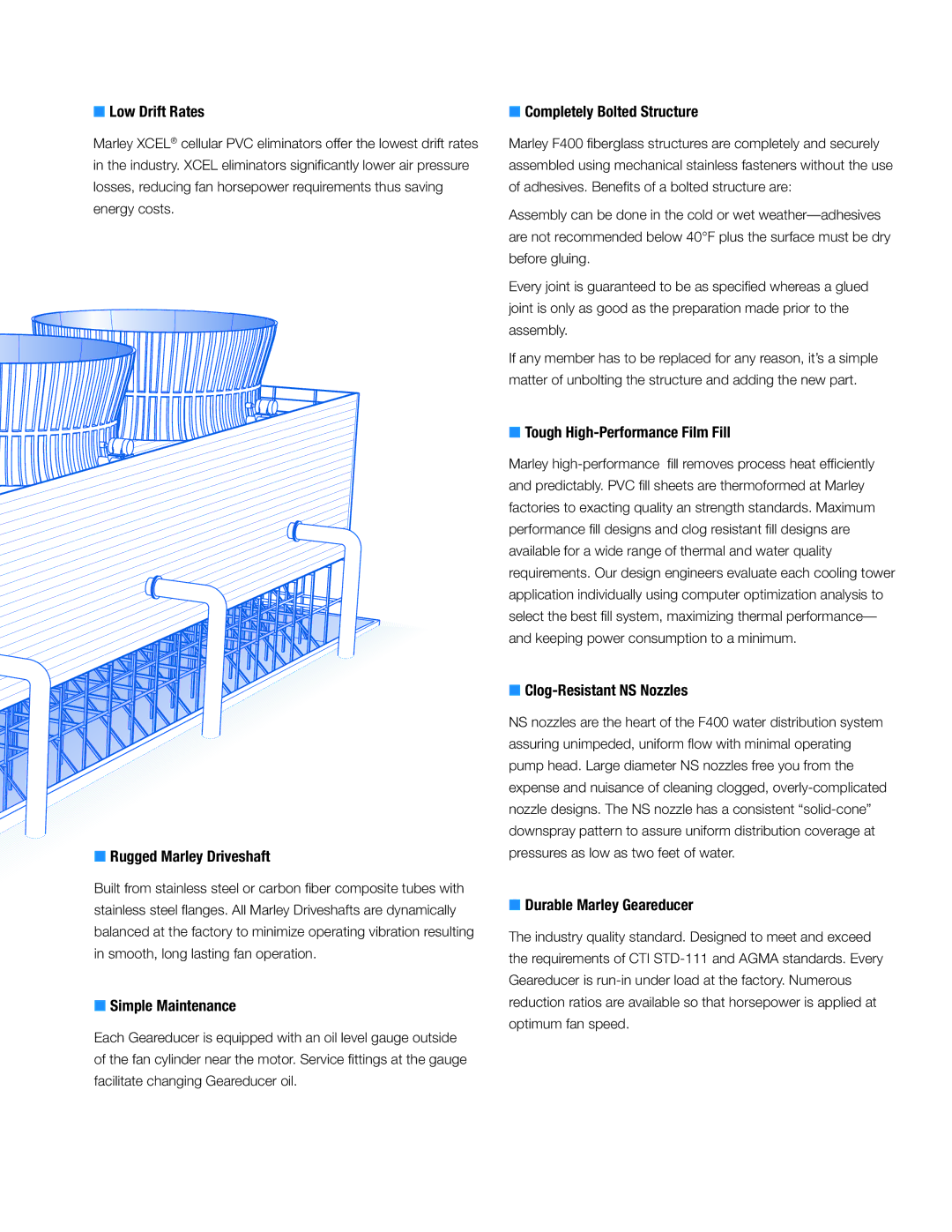

The F400 employs patented air and water flow technologies that enhance its heat transfer capabilities. The combination of optimized fan design and advanced drift eliminators maximizes air circulation while minimizing water loss, making it an environmentally friendly choice. The use of high-efficiency fans contributes to lower energy consumption, thus reducing operational costs and supporting sustainability initiatives.

Another key characteristic of the F400 is its durable construction. Built with corrosion-resistant materials and components, it is designed to withstand harsh environmental conditions, ensuring longevity and reliability. The tower's modular fill design enhances thermal performance while simplifying maintenance, as individual components can be accessed easily for inspection and cleaning.

The F400 is equipped with advanced monitoring and control systems that enable real-time performance assessments. These systems provide operators with valuable insights into operational efficiency, enabling proactive maintenance and troubleshooting, further enhancing productivity while reducing downtime.

Additionally, the F400’s quiet operation is a significant benefit for installations in urban or noise-sensitive areas. The sound suppression features ensure that the cooling tower blends seamlessly into its surroundings without causing disturbances.

Overall, the SPX Cooling Technologies F400 represents a significant leap forward in cooling tower technology, combining efficiency, adaptability, and durability. Its features make it a leading choice for industries that require dependable cooling solutions, underscoring SPX Cooling Technologies' commitment to innovation and excellence in thermal management.