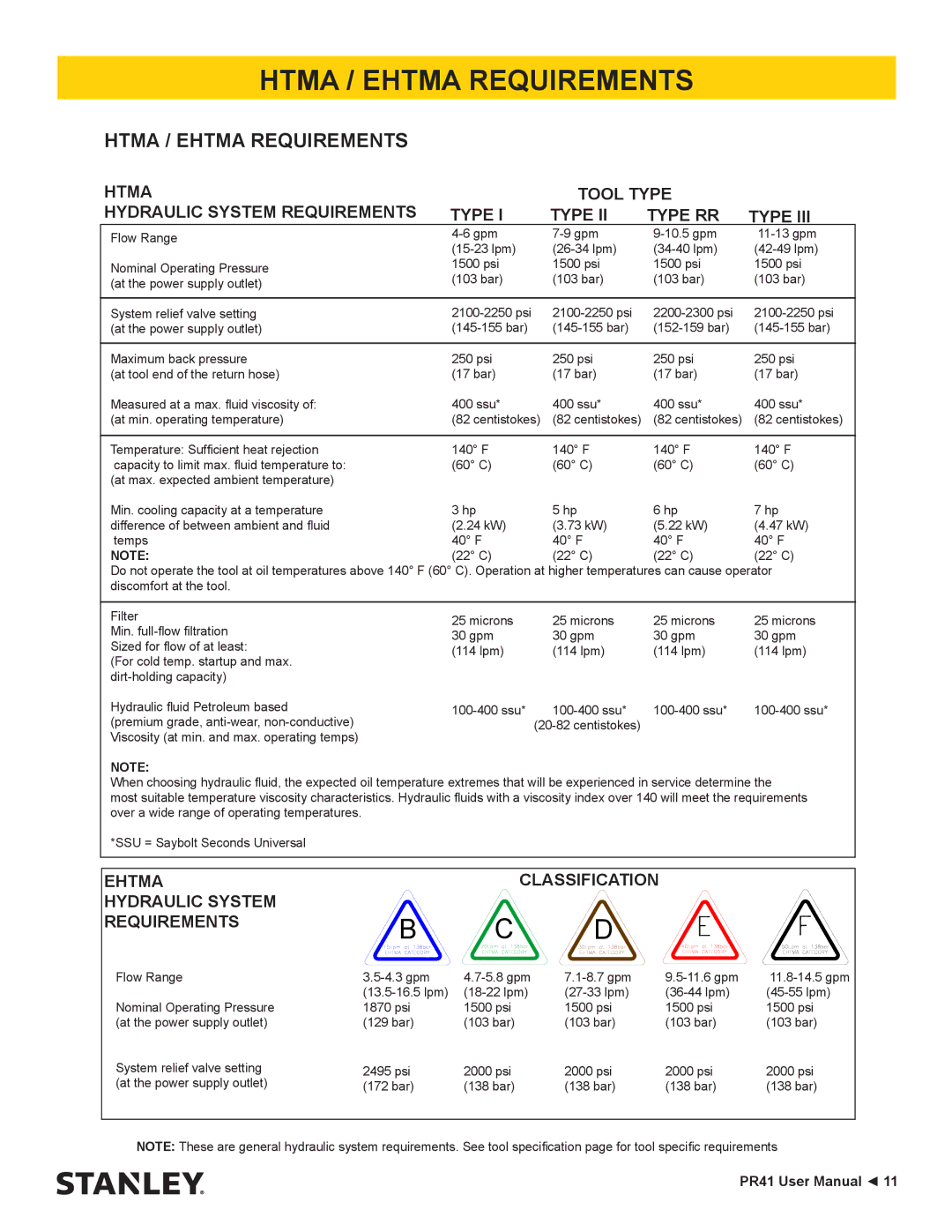

HTMA / EHTMA REQUIREMENTS

HTMA / EHTMA REQUIREMENTS

HTMA |

| TOOL TYPE |

| ||

HYDRAULIC SYSTEM REQUIREMENTS | TYPE I | TYPE II | TYPE RR | TYPE III | |

Flow Range | |||||

| |||||

Nominal Operating Pressure | 1500 psi | 1500 psi | 1500 psi | 1500 psi | |

(103 bar) | (103 bar) | (103 bar) | (103 bar) | ||

(at the power supply outlet) | |||||

|

|

|

| ||

|

|

|

|

| |

System relief valve setting | |||||

(at the power supply outlet) | |||||

|

|

|

|

| |

Maximum back pressure | 250 psi | 250 psi | 250 psi | 250 psi | |

(at tool end of the return hose) | (17 bar) | (17 bar) | (17 bar) | (17 bar) | |

Measured at a max. fluid viscosity of: | 400 ssu* | 400 ssu* | 400 ssu* | 400 ssu* | |

(at min. operating temperature) | (82 centistokes) | (82 centistokes) | (82 centistokes) | (82 centistokes) | |

|

|

|

|

| |

Temperature: Sufficient heat rejection | 140° F | 140° F | 140° F | 140° F | |

capacity to limit max. fluid temperature to: | (60° C) | (60° C) | (60° C) | (60° C) | |

(at max. expected ambient temperature) |

|

|

|

| |

Min. cooling capacity at a temperature | 3 hp | 5 hp | 6 hp | 7 hp | |

difference of between ambient and fluid | (2.24 kW) | (3.73 kW) | (5.22 kW) | (4.47 kW) | |

temps | 40° F | 40° F | 40° F | 40° F | |

NOTE: | (22° C) | (22° C) | (22° C) | (22° C) | |

Do not operate the tool at oil temperatures above 140° F (60° C). Operation at higher temperatures can cause operator discomfort at the tool.

Filter

Min.

(For cold temp. startup and max.

25 microns | 25 microns | 25 microns | 25 microns |

30 gpm | 30 gpm | 30 gpm | 30 gpm |

(114 lpm) | (114 lpm) | (114 lpm) | (114 lpm) |

Hydraulic fluid Petroleum based | ||||

(premium grade, |

|

|

| |

Viscosity (at min. and max. operating temps) |

|

|

|

|

NOTE:

When choosing hydraulic fluid, the expected oil temperature extremes that will be experienced in service determine the

most suitable temperature viscosity characteristics. Hydraulic fluids with a viscosity index over 140 will meet the requirements over a wide range of operating temperatures.

*SSU = Saybolt Seconds Universal

EHTMA |

| CLASSIFICATION |

|

| |

HYDRAULIC SYSTEM |

|

|

|

|

|

REQUIREMENTS | B | C | D |

|

|

|

|

| |||

Flow Range | |||||

| |||||

Nominal Operating Pressure | 1870 psi | 1500 psi | 1500 psi | 1500 psi | 1500 psi |

(at the power supply outlet) | (129 bar) | (103 bar) | (103 bar) | (103 bar) | (103 bar) |

System relief valve setting | 2495 psi | 2000 psi | 2000 psi | 2000 psi | 2000 psi |

(at the power supply outlet) | (172 bar) | (138 bar) | (138 bar) | (138 bar) | (138 bar) |

NOTE: These are general hydraulic system requirements. See tool specification page for tool specific requirements

PR41 User Manual ◄ 11