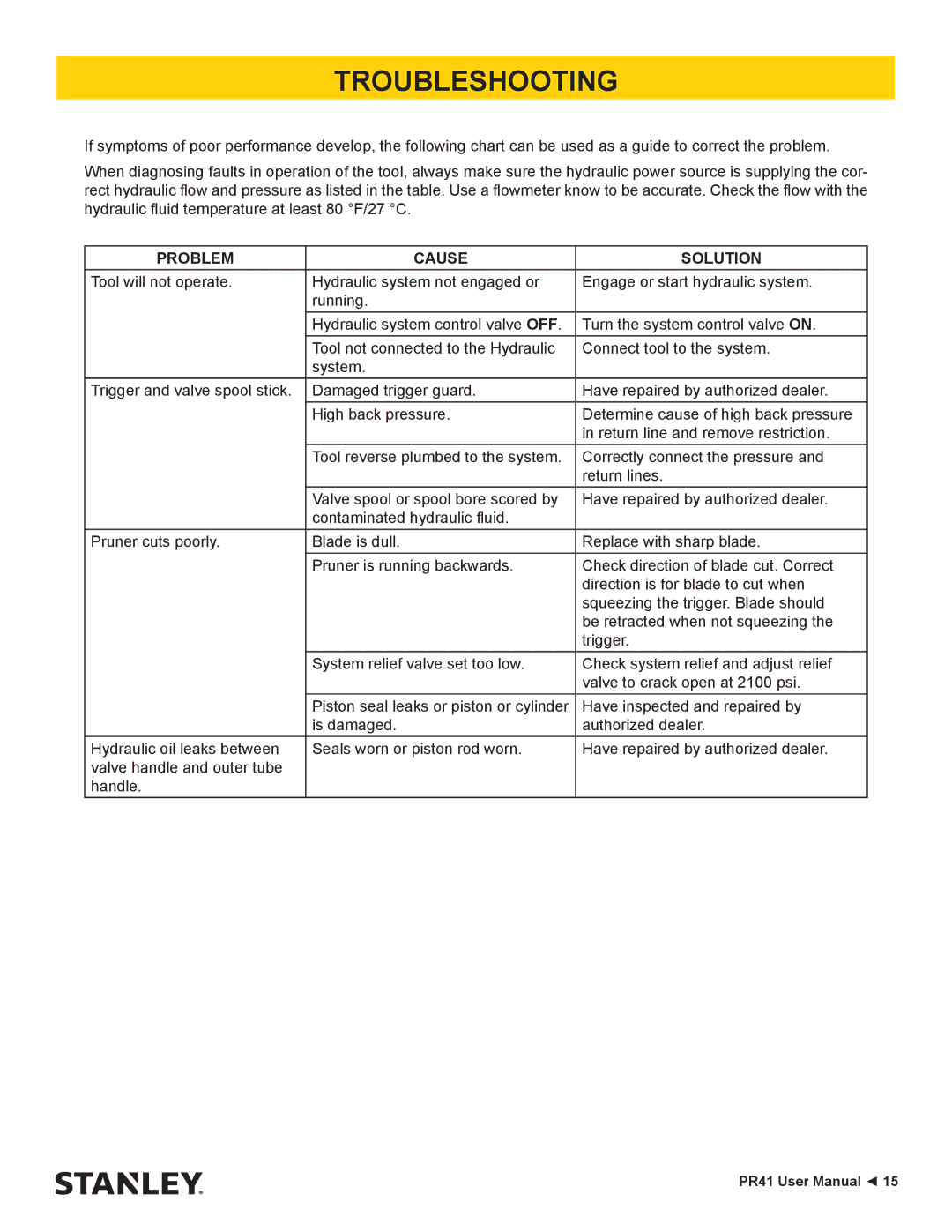

TROUBLESHOOTING

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the tool, always make sure the hydraulic power source is supplying the cor- rect hydraulic flow and pressure as listed in the table. Use a flowmeter know to be accurate. Check the flow with the hydraulic fluid temperature at least 80 °F/27 °C.

PROBLEM | CAUSE | SOLUTION |

Tool will not operate. | Hydraulic system not engaged or | Engage or start hydraulic system. |

| running. |

|

| Hydraulic system control valve OFF. | Turn the system control valve ON. |

| Tool not connected to the Hydraulic | Connect tool to the system. |

| system. |

|

Trigger and valve spool stick. | Damaged trigger guard. | Have repaired by authorized dealer. |

| High back pressure. | Determine cause of high back pressure |

|

| in return line and remove restriction. |

| Tool reverse plumbed to the system. | Correctly connect the pressure and |

|

| return lines. |

| Valve spool or spool bore scored by | Have repaired by authorized dealer. |

| contaminated hydraulic fluid. |

|

Pruner cuts poorly. | Blade is dull. | Replace with sharp blade. |

| Pruner is running backwards. | Check direction of blade cut. Correct |

|

| direction is for blade to cut when |

|

| squeezing the trigger. Blade should |

|

| be retracted when not squeezing the |

|

| trigger. |

| System relief valve set too low. | Check system relief and adjust relief |

|

| valve to crack open at 2100 psi. |

| Piston seal leaks or piston or cylinder | Have inspected and repaired by |

| is damaged. | authorized dealer. |

Hydraulic oil leaks between | Seals worn or piston rod worn. | Have repaired by authorized dealer. |

valve handle and outer tube |

|

|

handle. |

|

|

PR41 User Manual ◄ 15