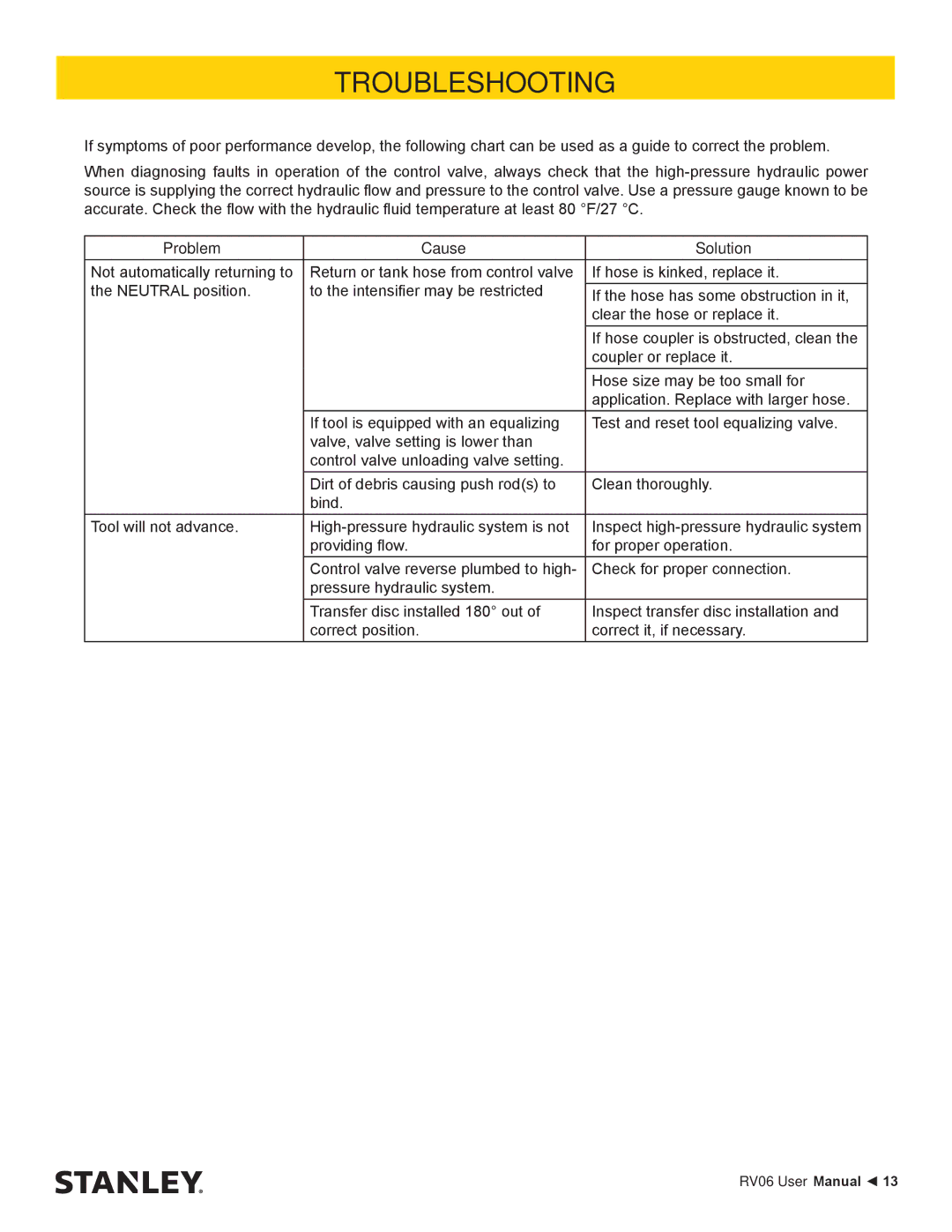

TROUBLESHOOTING

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the control valve, always check that the

Problem | Cause | Solution |

Not automatically returning to | Return or tank hose from control valve | If hose is kinked, replace it. |

the NEUTRAL position. | to the intensifier may be restricted | If the hose has some obstruction in it, |

|

| clear the hose or replace it. |

|

| If hose coupler is obstructed, clean the |

|

| coupler or replace it. |

|

| Hose size may be too small for |

|

| application. Replace with larger hose. |

| If tool is equipped with an equalizing | Test and reset tool equalizing valve. |

| valve, valve setting is lower than |

|

| control valve unloading valve setting. |

|

| Dirt of debris causing push rod(s) to | Clean thoroughly. |

| bind. |

|

Tool will not advance. | Inspect | |

| providing flow. | for proper operation. |

| Control valve reverse plumbed to high- | Check for proper connection. |

| pressure hydraulic system. |

|

| Transfer disc installed 180° out of | Inspect transfer disc installation and |

| correct position. | correct it, if necessary. |

RV06 User Manual ◄ 13