any direction. If the heater is installed in a carpeted alcove, the entire floor shall be covered by the panel. Also, see the DRAINING requirements in MAINTENANCE Section.

THE HEATER SHALL BE LOCATED OR PROTECTED SO IT IS NOT SUBJECT TO PHYSICAL DAMAGE BY A MOVING VEHICLE.

![]() WARNING

WARNING

FLAMMABLE ITEMS, PRESSURIZED CONTAINERS OR ANY OTHER POTENTIAL FIRE HAZARDOUS ARTICLES MUST NEVER BE PLACED ON ORADJACENT TO THE HEATER. OPEN CONTAINERS OR FLAMMABLE MATERIAL SHOULD NOT BE STORED OR USED IN THE SAME ROOM WITH THE HEATER.

THE HEATER MUST NOT BE LOCATED IN AN AREA WHERE IT WILL BE SUBJECT TO FREEZING.

LOCATE IT NEAR A FLOOR DRAIN. THE HEATER SHOULD BE LOCATED IN AN AREA WHERE LEAKAGE FROM THE HEATER OR CONNECTIONS WILL NOT RESULT IN DAMAGE TO THE ADJACENT AREA OR TO LOWER FLOORS OF THE STRUCTURE.

WHEN SUCH LOCATIONS CANNOT BE AVOIDED, A SUITABLE DRAIN PAN SHOULD BE INSTALLED UNDER THE HEATER. Such pans should be fabricated with sides at least 2" (50.8 mm) deep, with length and width at least 2" (50.8 mm) greater than the diameter of the heater and must be piped to an adequate drain. The pan must not restrict combustion air flow.

LEVELING

If the unit is not level, insert the bolts which were used in crating into the legs to correct this condition.

CLEARANCES

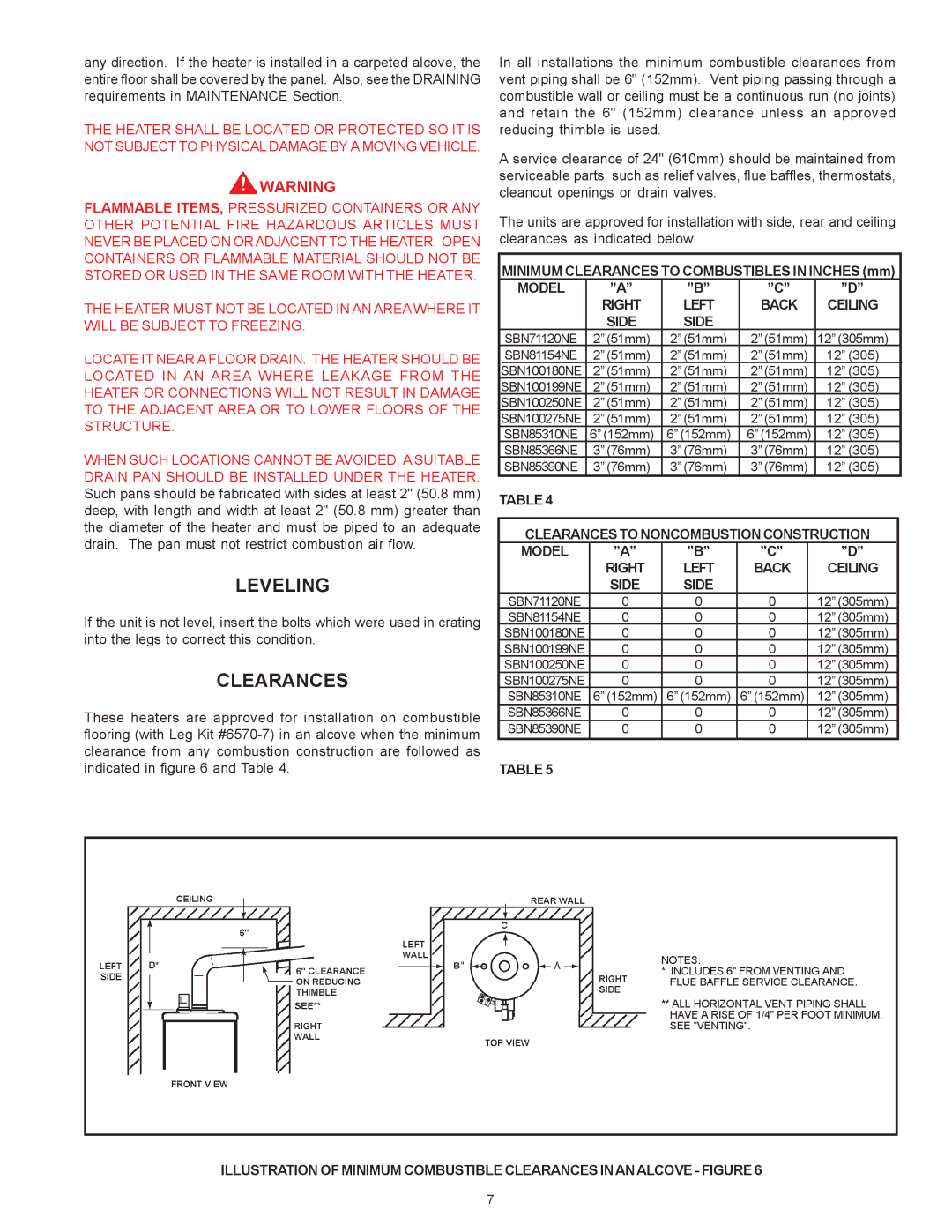

These heaters are approved for installation on combustible flooring (with Leg Kit

In all installations the minimum combustible clearances from vent piping shall be 6" (152mm). Vent piping passing through a combustible wall or ceiling must be a continuous run (no joints) and retain the 6" (152mm) clearance unless an approved reducing thimble is used.

A service clearance of 24" (610mm) should be maintained from serviceable parts, such as relief valves, flue baffles, thermostats, cleanout openings or drain valves.

The units are approved for installation with side, rear and ceiling clearances as indicated below:

MINIMUM CLEARANCES TO COMBUSTIBLES IN INCHES (mm)

| MODEL |

| ”A” | ”B” | ”C” | ”D” |

| |||

|

|

| RIGHT | LEFT | BACK | CEILING |

| |||

|

|

| SIDE | SIDE |

|

|

|

|

|

|

| SBN71120NE |

| 2” (51mm) | 2” (51mm) | 2” (51mm) | 12” (305mm) |

| |||

| SBN81154NE |

| 2” (51mm) | 2” (51mm) | 2” (51mm) | 12” (305) |

| |||

| SBN100180NE |

| 2” (51mm) | 2” (51mm) | 2” (51mm) | 12” (305) |

| |||

SBN100199NE |

| 2” (51mm) | 2” (51mm) | 2” (51mm) | 12” (305) |

| ||||

SBN100250NE |

| 2” (51mm) | 2” (51mm) | 2” (51mm) | 12” (305) |

| ||||

SBN100275NE |

| 2” (51mm) | 2” (51mm) | 2” (51mm) | 12” (305) |

| ||||

| SBN85310NE |

| 6” (152mm) | 6” (152mm) | 6” (152mm) | 12” (305) |

| |||

| SBN85366NE |

| 3” (76mm) | 3” (76mm) | 3” (76mm) | 12” (305) |

| |||

| SBN85390NE |

| 3” (76mm) | 3” (76mm) | 3” (76mm) | 12” (305) |

| |||

TABLE 4 |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

| CLEARANCES TO NONCOMBUSTION CONSTRUCTION |

| ||||||||

| MODEL | ”A” | ”B” | ”C” |

| ”D” |

|

| ||

|

|

| RIGHT | LEFT | BACK |

| CEILING |

| ||

|

|

| SIDE | SIDE |

|

|

|

|

|

|

| SBN71120NE | 0 | 0 | 0 |

| 12” (305mm) |

|

|

| |

| SBN81154NE | 0 | 0 | 0 |

| 12” (305mm) |

| |||

| SBN100180NE | 0 | 0 | 0 |

| 12” (305mm) |

| |||

| SBN100199NE | 0 | 0 | 0 |

| 12” (305mm) |

| |||

| SBN100250NE | 0 | 0 | 0 |

| 12” (305mm) |

| |||

| SBN100275NE | 0 | 0 | 0 |

| 12” (305mm) |

| |||

| SBN85310NE | 6” (152mm) | 6” (152mm) | 6” (152mm) |

| 12” (305mm) |

| |||

| SBN85366NE | 0 | 0 | 0 |

| 12” (305mm) |

| |||

| SBN85390NE | 0 | 0 | 0 |

| 12” (305mm) |

| |||

TABLE 5

ILLUSTRATION OF MINIMUM COMBUSTIBLE CLEARANCES INANALCOVE - FIGURE 6

7