| 8 |

| Troubleshooting |

| |

|

|

|

|

|

|

| General Troubleshooting |

|

| ||

|

|

|

|

|

|

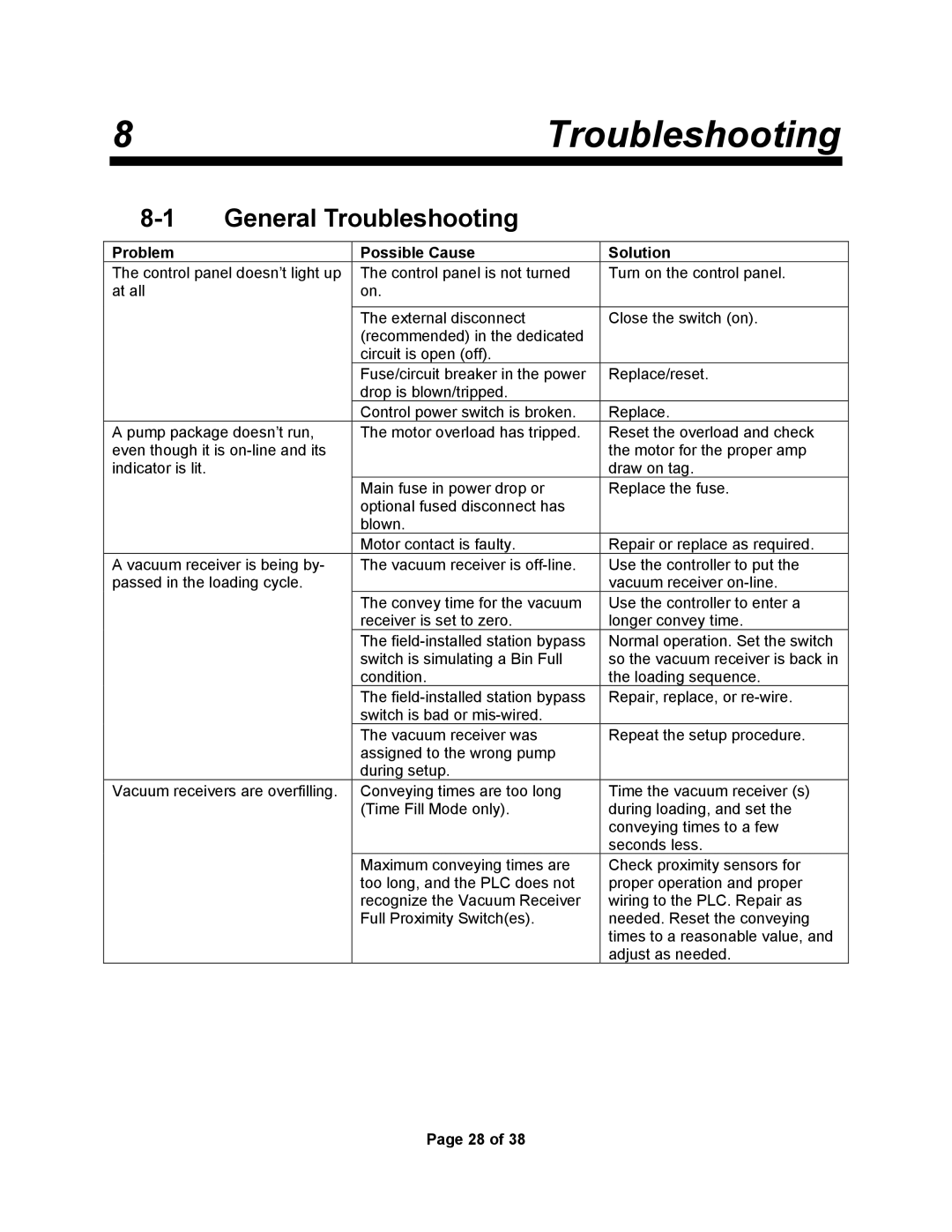

| Problem |

| Possible Cause | Solution |

|

| The control panel doesn’t light up | The control panel is not turned | Turn on the control panel. |

| |

| at all |

| on. |

|

|

|

|

|

|

|

|

|

|

| The external disconnect | Close the switch (on). |

|

|

|

| (recommended) in the dedicated |

|

|

|

|

| circuit is open (off). |

|

|

|

|

| Fuse/circuit breaker in the power | Replace/reset. |

|

|

|

| drop is blown/tripped. |

|

|

|

|

| Control power switch is broken. | Replace. |

|

| A pump package doesn’t run, | The motor overload has tripped. | Reset the overload and check |

| |

| even though it is |

| the motor for the proper amp |

| |

| indicator is lit. |

|

| draw on tag. |

|

|

|

| Main fuse in power drop or | Replace the fuse. |

|

|

|

| optional fused disconnect has |

|

|

|

|

| blown. |

|

|

|

|

| Motor contact is faulty. | Repair or replace as required. |

|

| A vacuum receiver is being by- | The vacuum receiver is | Use the controller to put the |

| |

| passed in the loading cycle. |

| vacuum receiver |

| |

|

|

| The convey time for the vacuum | Use the controller to enter a |

|

|

|

| receiver is set to zero. | longer convey time. |

|

|

|

| The | Normal operation. Set the switch |

|

|

|

| switch is simulating a Bin Full | so the vacuum receiver is back in |

|

|

|

| condition. | the loading sequence. |

|

|

|

| The | Repair, replace, or |

|

|

|

| switch is bad or |

|

|

|

|

| The vacuum receiver was | Repeat the setup procedure. |

|

|

|

| assigned to the wrong pump |

|

|

|

|

| during setup. |

|

|

| Vacuum receivers are overfilling. | Conveying times are too long | Time the vacuum receiver (s) |

| |

|

|

| (Time Fill Mode only). | during loading, and set the |

|

|

|

|

| conveying times to a few |

|

|

|

|

| seconds less. |

|

|

|

| Maximum conveying times are | Check proximity sensors for |

|

|

|

| too long, and the PLC does not | proper operation and proper |

|

|

|

| recognize the Vacuum Receiver | wiring to the PLC. Repair as |

|

|

|

| Full Proximity Switch(es). | needed. Reset the conveying |

|

|

|

|

| times to a reasonable value, and |

|

|

|

|

| adjust as needed. |

|

Page 28 of 38