GB | ENGLISH |

|

|

Change the spark plug if the electrodes are excessively burnt or if the plug is damaged. The engine manufacturers’ recommendations are as follows:

Briggs & Stratton: Champion J19LM (RJ19LM), Spark gap 0.76 mm.

Honda: NGK BPR6ES,

Spark gap

BATTERY (*)

The electrolyte in the battery is toxic and corrosive. It can cause serious corrosion damage etc. Avoid all contact with skin, eyes and clothing.

In normal use during the season, the battery is charged by the engine. If the engine cannot be started with the ignition key, it may be because the battery is ‘dead’.

Dismantle the battery by opening the battery cover, disconnecting the terminal on the engine and removing the battery (fig. 23). Connect the battery charger (provided) to the battery, then connect the charger to a wall socket and charge for 24 hours (fig. 24).

After charging, the battery may be reinstalled and the terminal on the battery connected to the terminal on the engine (fig. 25).

The battery charger may not be connected directly to the engine terminal. It is not possible to start the engine with the charger as the power source and the charger could be damaged.

WINTER STORAGE

Remove the battery and store it fully charged (see above) in a dry, cool place (between 0°C and +15°C). The battery should be maintenance- charged at least once during the winter storage period.

Before the start of the season, the battery should be charged once again for 24 hours.

ADJUSTING CLUTCH CABLE

If the drive does not engage when the clutch loop is pressed against the handle, or if the lawnmower feels cumbersome or slow, this may be because the clutch in the transmission is slipping. To rectify this situation, adjust the clutch cable as follows:

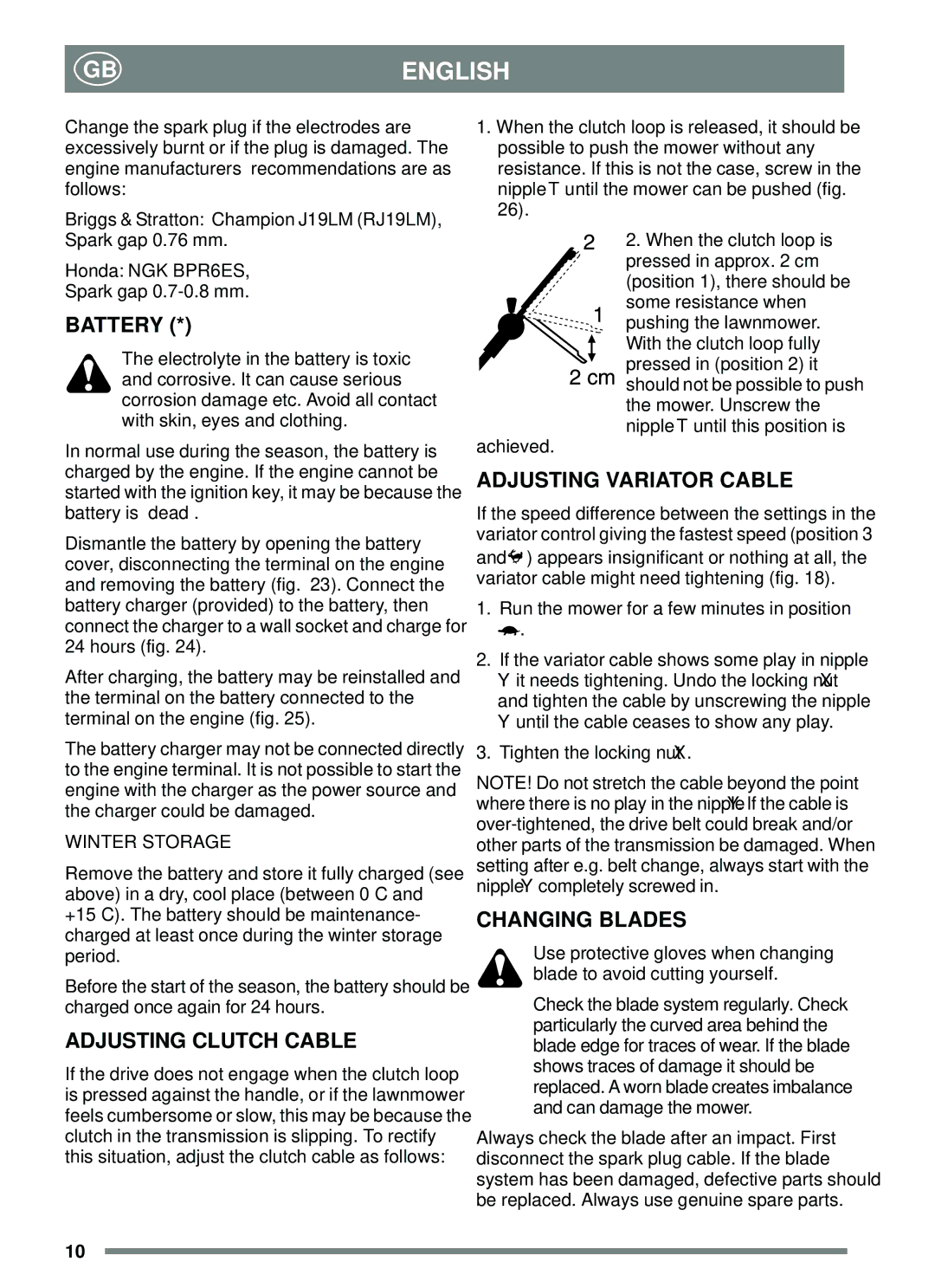

1.When the clutch loop is released, it should be possible to push the mower without any resistance. If this is not the case, screw in the nipple T until the mower can be pushed (fig. 26).

2. When the clutch loop is pressed in approx. 2 cm (position 1), there should be

some resistance when

pushing the lawnmower.

With the clutch loop fully

pressed in (position 2) it

should not be possible to push the mower. Unscrew the nipple T until this position is

achieved.

ADJUSTING VARIATOR CABLE

If the speed difference between the settings in the variator control giving the fastest speed (position 3 and ![]() ) appears insignificant or nothing at all, the variator cable might need tightening (fig. 18).

) appears insignificant or nothing at all, the variator cable might need tightening (fig. 18).

1.Run the mower for a few minutes in position

![]() .

.

2.If the variator cable shows some play in nipple Y it needs tightening. Undo the locking nut X and tighten the cable by unscrewing the nipple Y until the cable ceases to show any play.

3.Tighten the locking nut X.

NOTE! Do not stretch the cable beyond the point where there is no play in the nipple Y. If the cable is

CHANGING BLADES

Use protective gloves when changing blade to avoid cutting yourself.

Check the blade system regularly. Check particularly the curved area behind the blade edge for traces of wear. If the blade shows traces of damage it should be replaced. A worn blade creates imbalance and can damage the mower.

Always check the blade after an impact. First disconnect the spark plug cable. If the blade system has been damaged, defective parts should be replaced. Always use genuine spare parts.

10