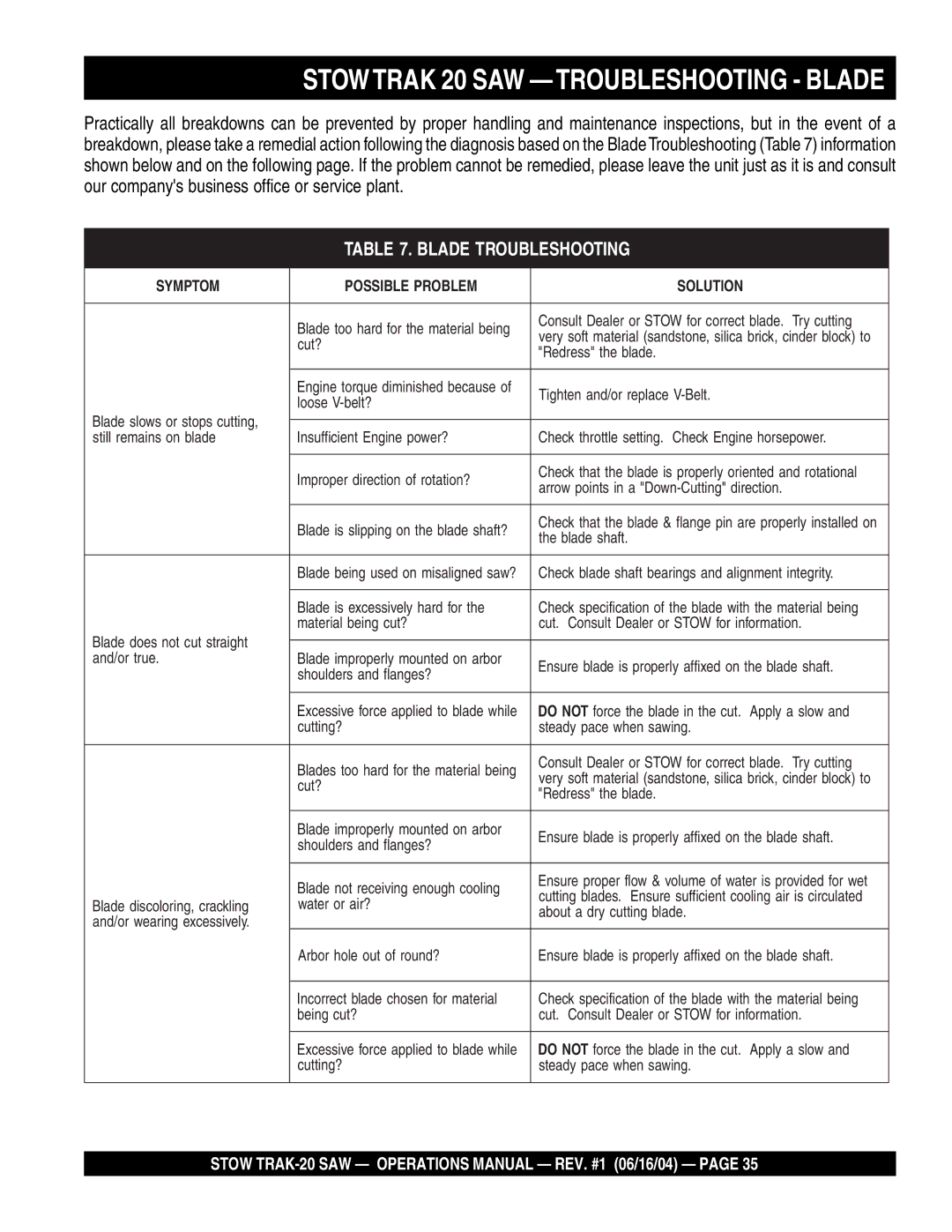

STOWTRAK 20 SAW —TROUBLESHOOTING - BLADE

Practically all breakdowns can be prevented by proper handling and maintenance inspections, but in the event of a breakdown, please take a remedial action following the diagnosis based on the Blade Troubleshooting (Table 7) information shown below and on the following page. If the problem cannot be remedied, please leave the unit just as it is and consult our company's business office or service plant.

TABLE 7. BLADE TROUBLESHOOTING

SYMPTOM | POSSIBLE PROBLEM | SOLUTION | |

|

|

| |

| Blade too hard for the material being | Consult Dealer or STOW for correct blade. Try cutting | |

| very soft material (sandstone, silica brick, cinder block) to | ||

| cut? | ||

| "Redress" the blade. | ||

|

| ||

|

|

| |

| Engine torque diminished because of | Tighten and/or replace | |

| loose | ||

|

| ||

Blade slows or stops cutting, |

|

| |

Insufficient Engine power? | Check throttle setting. Check Engine horsepower. | ||

still remains on blade | |||

|

|

| |

| Improper direction of rotation? | Check that the blade is properly oriented and rotational | |

| arrow points in a | ||

|

| ||

|

|

| |

| Blade is slipping on the blade shaft? | Check that the blade & flange pin are properly installed on | |

| the blade shaft. | ||

|

| ||

|

|

| |

| Blade being used on misaligned saw? | Check blade shaft bearings and alignment integrity. | |

|

|

| |

| Blade is excessively hard for the | Check specification of the blade with the material being | |

| material being cut? | cut. Consult Dealer or STOW for information. | |

Blade does not cut straight |

|

| |

|

| ||

and/or true. | Blade improperly mounted on arbor | Ensure blade is properly affixed on the blade shaft. | |

| shoulders and flanges? | ||

|

| ||

|

|

| |

| Excessive force applied to blade while | DO NOT force the blade in the cut. Apply a slow and | |

| cutting? | steady pace when sawing. | |

|

|

| |

| Blades too hard for the material being | Consult Dealer or STOW for correct blade. Try cutting | |

| very soft material (sandstone, silica brick, cinder block) to | ||

| cut? | ||

| "Redress" the blade. | ||

|

| ||

|

|

| |

| Blade improperly mounted on arbor | Ensure blade is properly affixed on the blade shaft. | |

| shoulders and flanges? | ||

|

| ||

|

|

| |

| Blade not receiving enough cooling | Ensure proper flow & volume of water is provided for wet | |

| cutting blades. Ensure sufficient cooling air is circulated | ||

Blade discoloring, crackling | water or air? | ||

about a dry cutting blade. | |||

and/or wearing excessively. |

| ||

|

| ||

| Arbor hole out of round? | Ensure blade is properly affixed on the blade shaft. | |

|

|

| |

| Incorrect blade chosen for material | Check specification of the blade with the material being | |

| being cut? | cut. Consult Dealer or STOW for information. | |

|

|

| |

| Excessive force applied to blade while | DO NOT force the blade in the cut. Apply a slow and | |

| cutting? | steady pace when sawing. | |

|

|

|