STOW TRAK 20 SAW — MAINTENANCE (SAW)

Cutting Head Alignment (Blade)

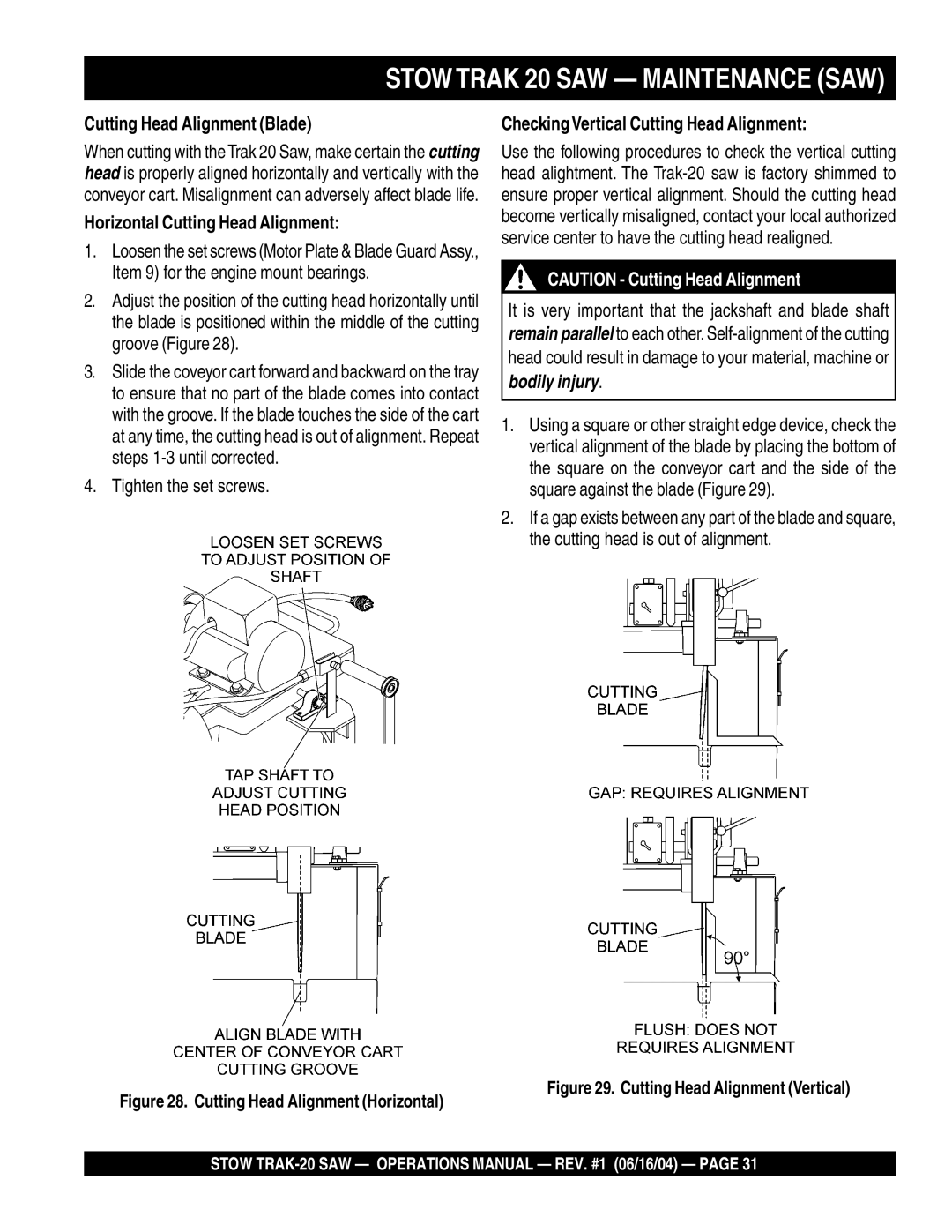

When cutting with the Trak 20 Saw, make certain the cutting head is properly aligned horizontally and vertically with the conveyor cart. Misalignment can adversely affect blade life.

Horizontal Cutting Head Alignment:

1.Loosen the set screws (Motor Plate & Blade Guard Assy., Item 9) for the engine mount bearings.

2.Adjust the position of the cutting head horizontally until the blade is positioned within the middle of the cutting groove (Figure 28).

3.Slide the coveyor cart forward and backward on the tray to ensure that no part of the blade comes into contact with the groove. If the blade touches the side of the cart at any time, the cutting head is out of alignment. Repeat steps

4.Tighten the set screws.

CheckingVertical Cutting Head Alignment:

Use the following procedures to check the vertical cutting head alightment. The

CAUTION - Cutting Head Alignment

It is very important that the jackshaft and blade shaft remain parallel to each

1.Using a square or other straight edge device, check the vertical alignment of the blade by placing the bottom of the square on the conveyor cart and the side of the square against the blade (Figure 29).

2.If a gap exists between any part of the blade and square, the cutting head is out of alignment.