ASSEMBLY INSTRUCTIONS/OPERATION

Assembly

The STOW SFCS16 FLOOR COVERING SCRAPER is shipped from the factory secured on a specially designed wooden pallet and protected from external damage by a corrugated carton or wood crate. If shipped with a corrugated carton, the Surface Grinder is secured to the pallet with wood support strips. Remove the carton or crate immediately upon receipt using suitable tools to remove the nails.

REMOVING THE FLOOR COVERING SCRAPER FROM THE PALLET.

Tools Required:

1 each, cutting type pliers.

1 each, claw hammer or a hammer and an appropriate pry bar.

Remove the corrugated carton which is fastened to the pallet. The FLOOR COVERING SCRAPER is secured to the pallet with banding. Using the pliers, cut and remove the banding. The FLOOR COVERING SCRAPER can then be removed from the pallet.

![]() DANGER

DANGER

WEAR SAFETY GLASSES AND OTHER APPROPRIATE SAFETY APPAREL WHEN CUTTING THE BANDING AND/OR REMOVING THE CORRUGATED/WOOD SHIPPING CRATE.

Included in the shipment should be the following:

1 each, FLOOR COVERING SCRAPER main frame assembly.

1 each, extension cord with integral GFI.

1 each, adjustable section of the operator handle.

1 each, pack of standard blades.

The FLOOR COVERING SCRAPER is shipped from the factory completely assembled with the exception of the adjustable section of the operator handle. If ordered with the Surface Grinder, optional blades and accessories can be shipped separately or included in the shipping container.

Visually inspect the shipment for freight damage and/or missing parts. If shipping damage is evident, contact the delivering carrier immediately to arrange for an inspection of the damage by its claims representative. Federal law requires that a claim be filed within a specific time period. If missing parts are detected, notify your dealer or the Customer Service Department who will assist you in obtaining them.

Check all fasteners for proper security. Consult a fastener torque chart for the proper torque value if any fastener is found to require retorquing.

INSTALLATION OF THE ADJUSTABLE SECTION OF THE OPERATOR HANDLE.

The installation of the adjustable section of the operator will require a level working surface of sufficient size and appropriate height.

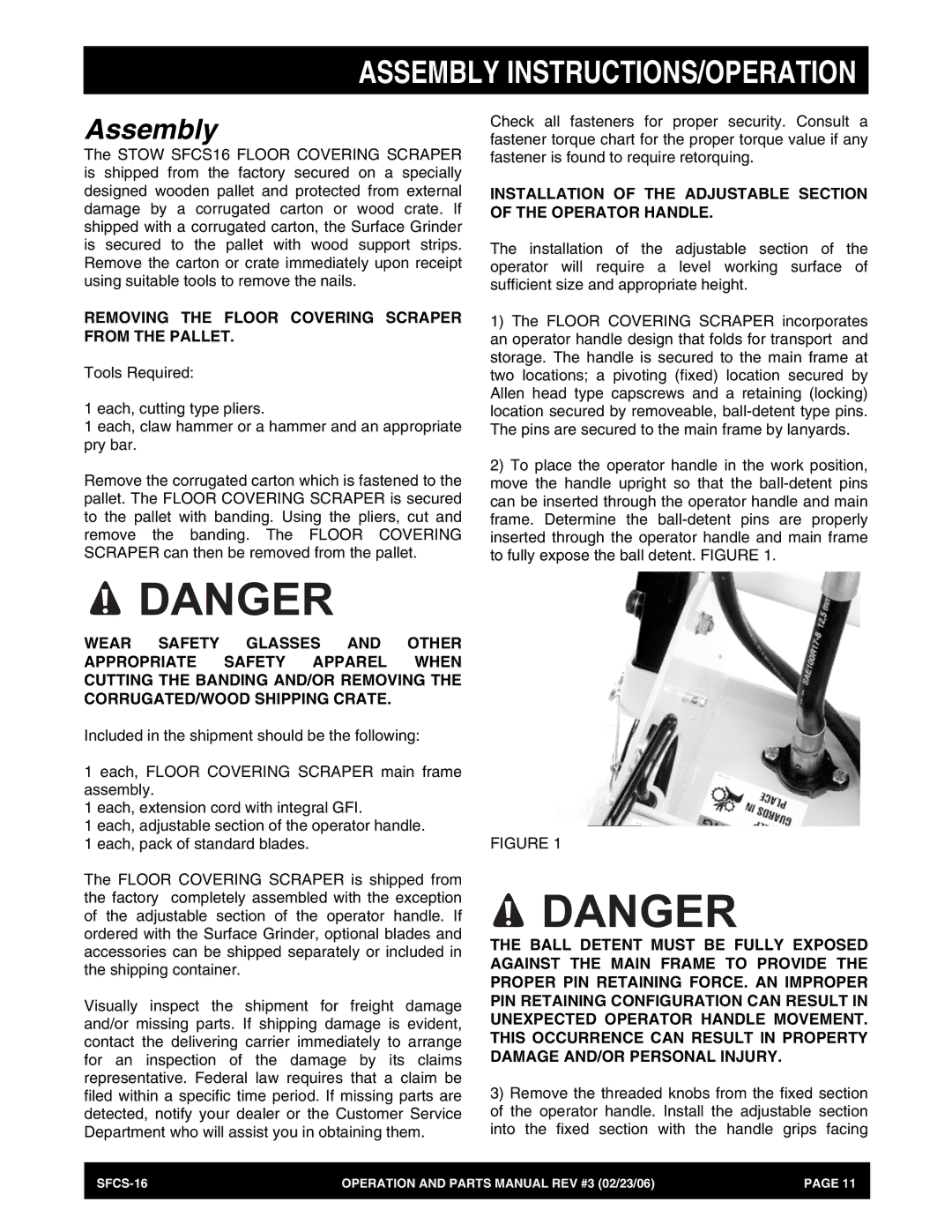

1)The FLOOR COVERING SCRAPER incorporates an operator handle design that folds for transport and storage. The handle is secured to the main frame at two locations; a pivoting (fixed) location secured by Allen head type capscrews and a retaining (locking) location secured by removeable,

2)To place the operator handle in the work position, move the handle upright so that the

FIGURE 1

![]() DANGER

DANGER

THE BALL DETENT MUST BE FULLY EXPOSED AGAINST THE MAIN FRAME TO PROVIDE THE PROPER PIN RETAINING FORCE. AN IMPROPER PIN RETAINING CONFIGURATION CAN RESULT IN UNEXPECTED OPERATOR HANDLE MOVEMENT. THIS OCCURRENCE CAN RESULT IN PROPERTY DAMAGE AND/OR PERSONAL INJURY.

3)Remove the threaded knobs from the fixed section of the operator handle. Install the adjustable section into the fixed section with the handle grips facing

| OPERATION AND PARTS MANUAL REV #3 (02/23/06) | PAGE 11 |

|

|

|