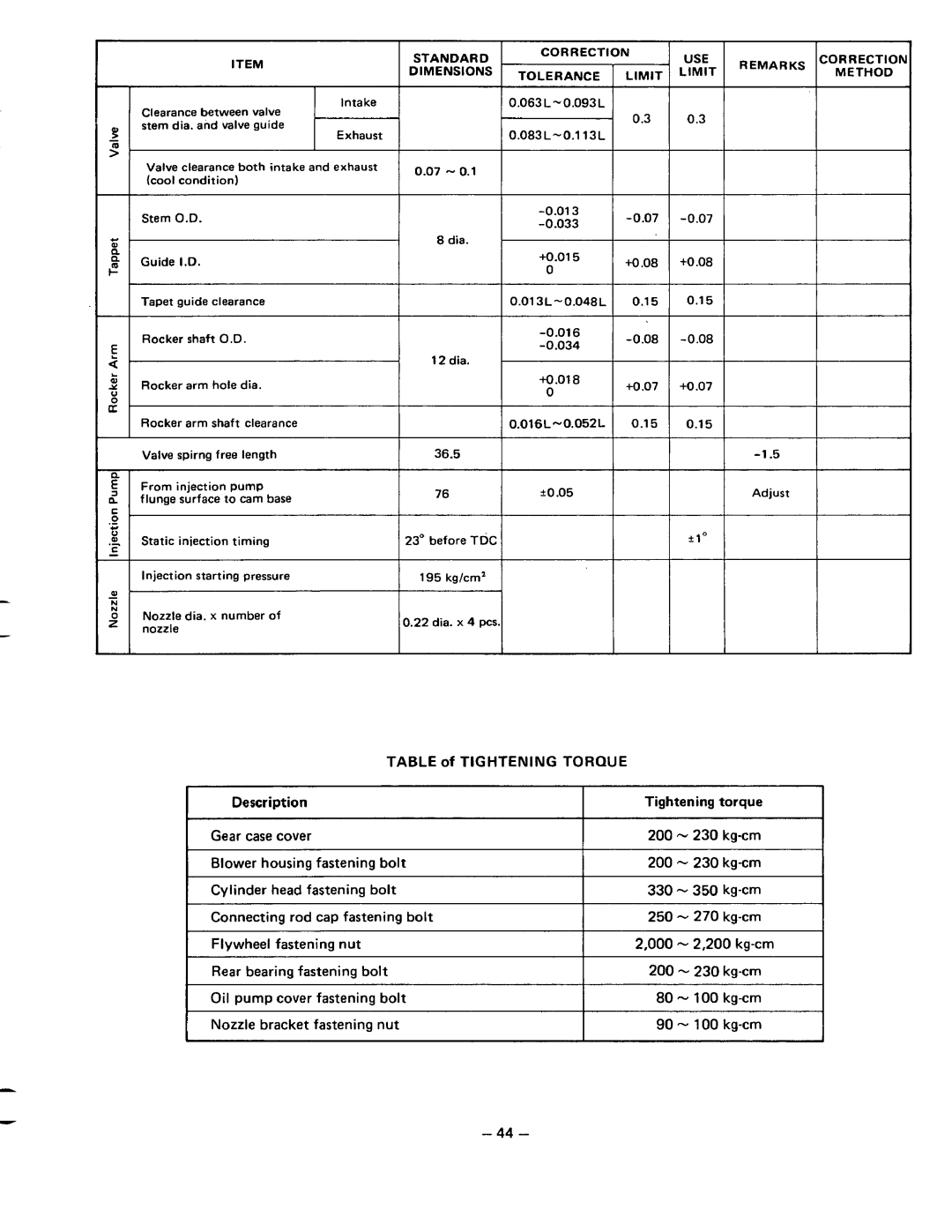

DY41, DY30, DY35 specifications

Subaru Robin Power Products have built a solid reputation in the realm of portable engines and generators, particularly with their DY35, DY30, and DY41 models. These engines are extensively used for various applications, ranging from construction to agricultural equipment, owing to their reliability and efficiency.The Subaru DY35 engine exemplifies performance with a displacement of 35cc. Its lightweight design ensures easy portability, while its robust construction provides durability in demanding environments. Featuring a two-stroke cycle, the DY35 offers a high power-to-weight ratio, making it ideal for handheld equipment and compact machinery. Key characteristics include its advanced electronic ignition system that promotes easy starting and reliable operation. The DY35 also boasts superior fuel efficiency, which translates to lower operational costs over time.

Moving on to the DY30, this engine is designed with versatility in mind. It has a slightly smaller displacement of 30cc, making it a great choice for various power tools and smaller machinery. The DY30 is known for its excellent torque delivery, which allows users to tackle challenging tasks without the need for frequent refueling. One of its standout features is the automatic lubrication system that keeps the engine running smoothly while minimizing wear and tear. This feature significantly extends the engine’s life, making it a favorite among users looking for long-term performance.

The DY41 takes a step up in power with a displacement of 41cc, making it suitable for heavier-duty applications. Designed for larger equipment, the DY41 is renowned for its high torque and robust construction. It also includes an innovative cooling system that effectively dissipates heat, ensuring optimal engine performance in prolonged usage scenarios. The DY41 is equipped with advanced vibration-dampening technology, which enhances user comfort and reduces fatigue during operation.

Each of these Subaru Robin engines incorporates fuel-efficient technologies that reduce emissions and comply with environmental regulations. They are built to withstand the rigors of demanding work environments while providing reliable power. With their distinct features and durable designs, the DY35, DY30, and DY41 engines continue to be sought-after choices for professionals and hobbyists alike, underscoring Subaru's commitment to innovation and quality in power products.