6

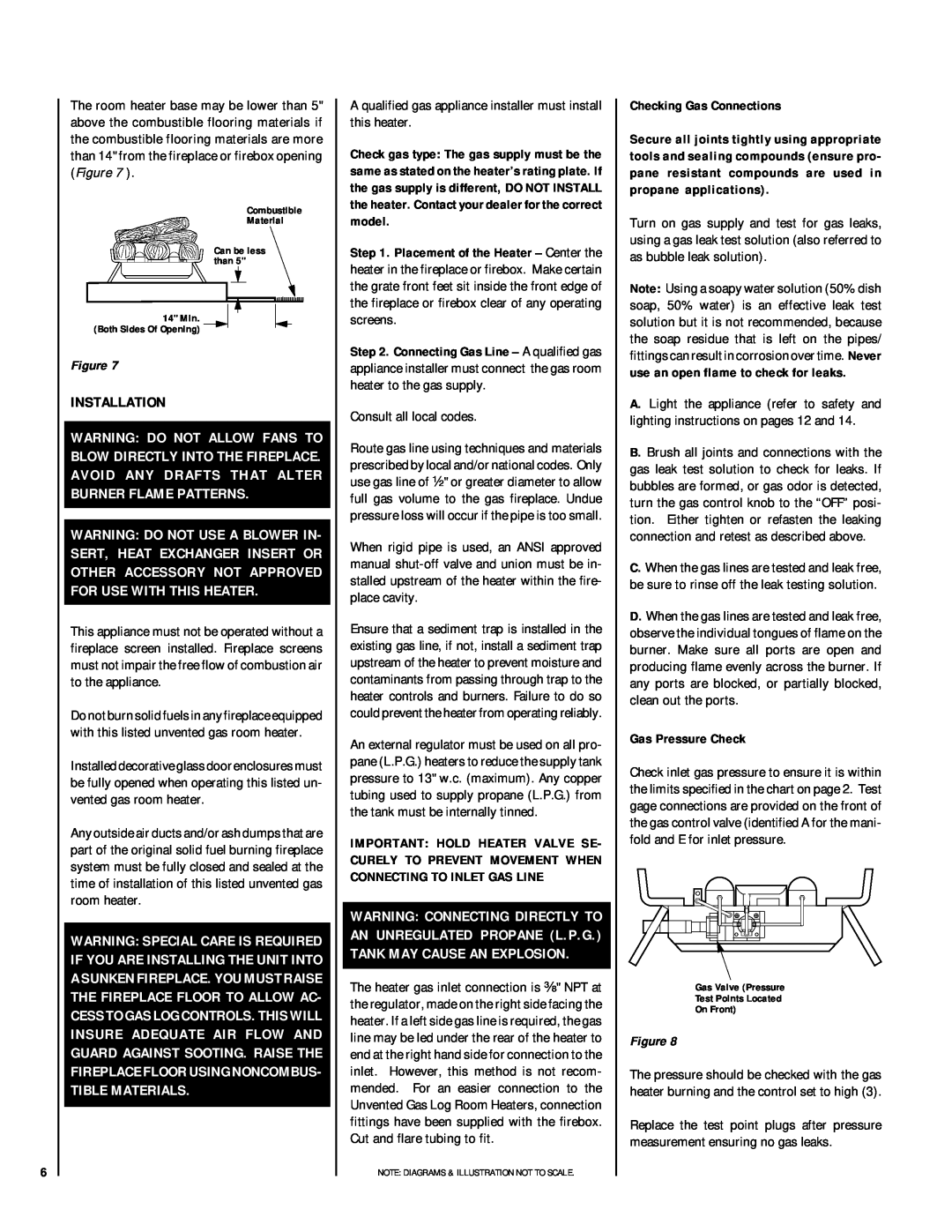

The room heater base may be lower than 5" above the combustible flooring materials if the combustible flooring materials are more than 14" from the fireplace or firebox opening (Figure 7 ).

Combustible

Material

Can be less than 5"

14" Min.

(Both Sides Of Opening)

Figure 7

INSTALLATION

WARNING: DO NOT ALLOW FANS TO BLOW DIRECTLY INTO THE FIREPLACE. AVOID ANY DRAFTS THAT ALTER BURNER FLAME PATTERNS.

WARNING: DO NOT USE A BLOWER IN- SERT, HEAT EXCHANGER INSERT OR OTHER ACCESSORY NOT APPROVED FOR USE WITH THIS HEATER.

This appliance must not be operated without a fireplace screen installed. Fireplace screens must not impair the free flow of combustion air to the appliance.

Do not burn solid fuels in any fireplace equipped with this listed unvented gas room heater.

Installed decorative glass door enclosures must be fully opened when operating this listed un- vented gas room heater.

Any outside air ducts and/or ash dumps that are part of the original solid fuel burning fireplace system must be fully closed and sealed at the time of installation of this listed unvented gas room heater.

WARNING: SPECIAL CARE IS REQUIRED IF YOU ARE INSTALLING THE UNIT INTO A SUNKEN FIREPLACE. YOU MUST RAISE THE FIREPLACE FLOOR TO ALLOW AC- CESS TO GAS LOG CONTROLS. THIS WILL INSURE ADEQUATE AIR FLOW AND GUARD AGAINST SOOTING. RAISE THE FIREPLACE FLOOR USING NONCOMBUS- TIBLE MATERIALS.

A qualified gas appliance installer must install this heater.

Check gas type: The gas supply must be the same as stated on the heater’s rating plate. If the gas supply is different, DO NOT INSTALL the heater. Contact your dealer for the correct model.

Step 1. Placement of the Heater – Center the heater in the fireplace or firebox. Make certain the grate front feet sit inside the front edge of the fireplace or firebox clear of any operating screens.

Step 2. Connecting Gas Line – A qualified gas appliance installer must connect the gas room heater to the gas supply.

Consult all local codes.

Route gas line using techniques and materials prescribed by local and/or national codes. Only use gas line of ¹⁄₂" or greater diameter to allow full gas volume to the gas fireplace. Undue pressure loss will occur if the pipe is too small.

When rigid pipe is used, an ANSI approved manual

Ensure that a sediment trap is installed in the existing gas line, if not, install a sediment trap upstream of the heater to prevent moisture and contaminants from passing through trap to the heater controls and burners. Failure to do so could prevent the heater from operating reliably.

An external regulator must be used on all pro- pane (L.P.G.) heaters to reduce the supply tank pressure to 13" w.c. (maximum). Any copper tubing used to supply propane (L.P.G.) from the tank must be internally tinned.

IMPORTANT: HOLD HEATER VALVE SE- CURELY TO PREVENT MOVEMENT WHEN CONNECTING TO INLET GAS LINE

WARNING: CONNECTING DIRECTLY TO AN UNREGULATED PROPANE (L.P.G.) TANK MAY CAUSE AN EXPLOSION.

The heater gas inlet connection is ³⁄₈" NPT at the regulator, made on the right side facing the heater. If a left side gas line is required, the gas line may be led under the rear of the heater to end at the right hand side for connection to the inlet. However, this method is not recom- mended. For an easier connection to the Unvented Gas Log Room Heaters, connection fittings have been supplied with the firebox. Cut and flare tubing to fit.

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

Checking Gas Connections

Secure all joints tightly using appropriate tools and sealing compounds (ensure pro- pane resistant compounds are used in propane applications).

Turn on gas supply and test for gas leaks, using a gas leak test solution (also referred to as bubble leak solution).

Note: Using a soapy water solution (50% dish soap, 50% water) is an effective leak test solution but it is not recommended, because the soap residue that is left on the pipes/ fittings can result in corrosion over time. Never use an open flame to check for leaks.

A. Light the appliance (refer to safety and lighting instructions on pages 12 and 14.

B. Brush all joints and connections with the gas leak test solution to check for leaks. If bubbles are formed, or gas odor is detected, turn the gas control knob to the “OFF” posi- tion. Either tighten or refasten the leaking connection and retest as described above.

C. When the gas lines are tested and leak free, be sure to rinse off the leak testing solution.

D. When the gas lines are tested and leak free, observe the individual tongues of flame on the burner. Make sure all ports are open and producing flame evenly across the burner. If any ports are blocked, or partially blocked, clean out the ports.

Gas Pressure Check

Check inlet gas pressure to ensure it is within the limits specified in the chart on page 2. Test gage connections are provided on the front of the gas control valve (identified A for the mani- fold and E for inlet pressure.

Gas Valve (Pressure

Test Points Located

On Front)

Figure 8

The pressure should be checked with the gas heater burning and the control set to high (3).

Replace the test point plugs after pressure measurement ensuring no gas leaks.