REPAIRING OR REPLACING BLADE DRIVER

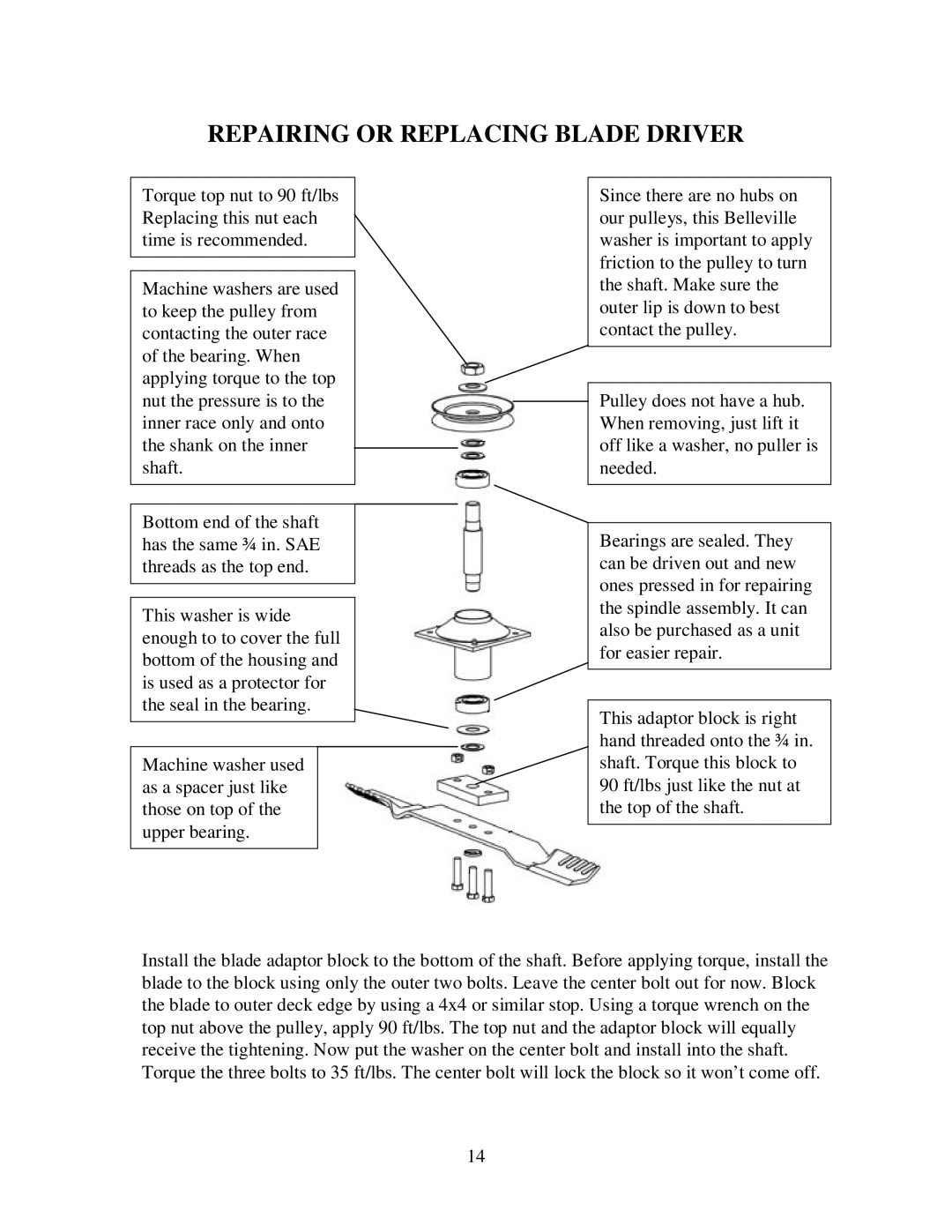

Torque top nut to 90 ft/lbs Replacing this nut each time is recommended.

Machine washers are used to keep the pulley from contacting the outer race of the bearing. When applying torque to the top nut the pressure is to the inner race only and onto the shank on the inner shaft.

Bottom end of the shaft has the same ¾ in. SAE threads as the top end.

This washer is wide enough to to cover the full bottom of the housing and is used as a protector for the seal in the bearing.

Machine washer used as a spacer just like those on top of the upper bearing.

Since there are no hubs on our pulleys, this Belleville washer is important to apply friction to the pulley to turn the shaft. Make sure the outer lip is down to best contact the pulley.

Pulley does not have a hub. When removing, just lift it off like a washer, no puller is needed.

Bearings are sealed. They can be driven out and new ones pressed in for repairing the spindle assembly. It can also be purchased as a unit for easier repair.

This adaptor block is right hand threaded onto the ¾ in. shaft. Torque this block to 90 ft/lbs just like the nut at the top of the shaft.

Install the blade adaptor block to the bottom of the shaft. Before applying torque, install the blade to the block using only the outer two bolts. Leave the center bolt out for now. Block the blade to outer deck edge by using a 4x4 or similar stop. Using a torque wrench on the top nut above the pulley, apply 90 ft/lbs. The top nut and the adaptor block will equally receive the tightening. Now put the washer on the center bolt and install into the shaft. Torque the three bolts to 35 ft/lbs. The center bolt will lock the block so it won’t come off.

14