CMS501

TECHNICAL SPECIFICATIONS

|

|

|

|

|

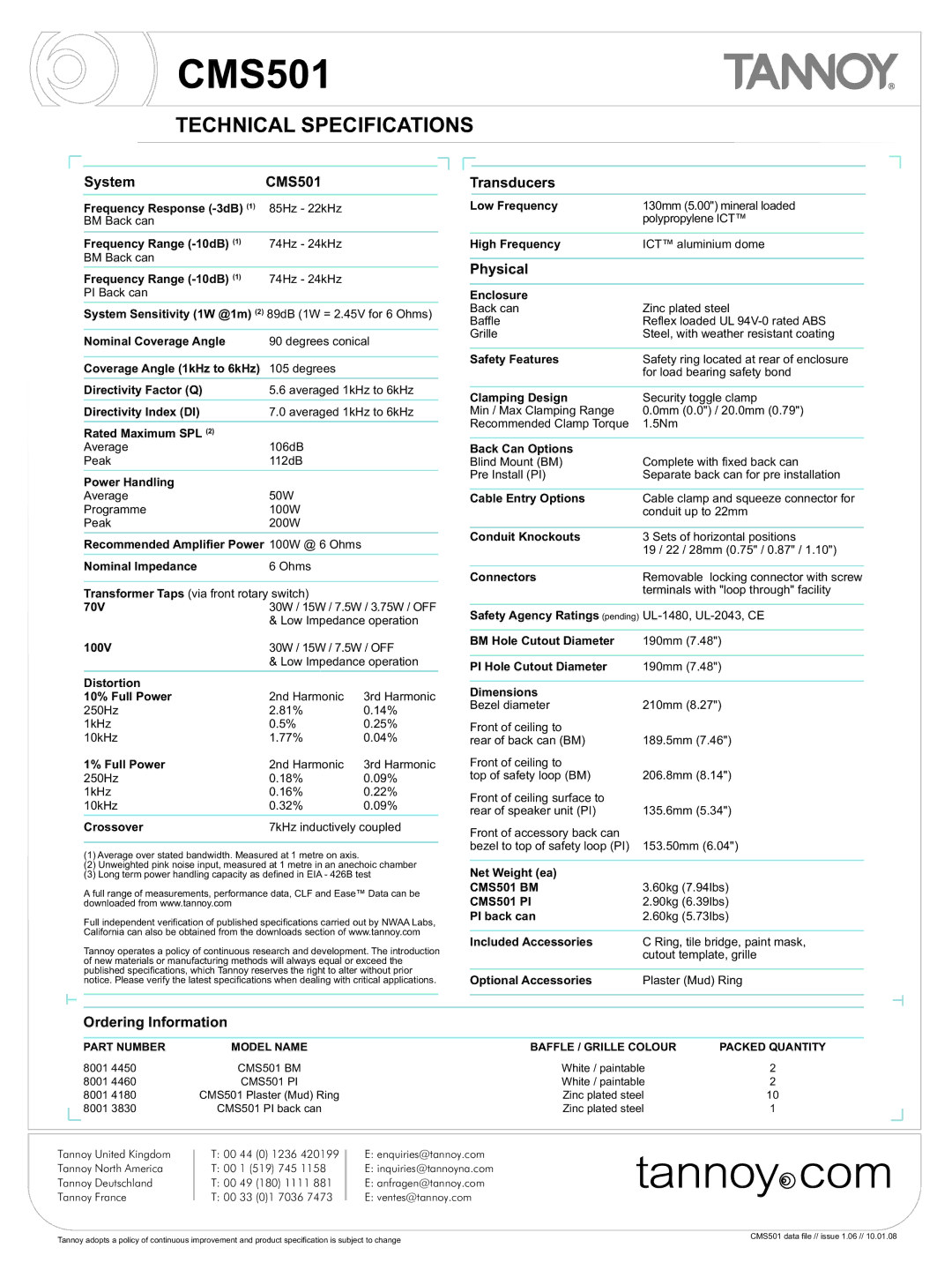

System | CMS501 |

|

|

|

Frequency Response | 85Hz - 22kHz |

|

|

|

BM Back can |

|

|

|

|

Frequency Range | 74Hz - 24kHz |

|

|

|

BM Back can |

|

|

|

|

Frequency Range | 74Hz - 24kHz |

|

|

|

PI Back can |

|

|

|

|

System Sensitivity (1W @1m) (2) | 89dB (1W = 2.45V for 6 Ohms) |

|

| |

Nominal Coverage Angle | 90 degrees conical |

|

| |

Coverage Angle (1kHz to 6kHz) | 105 degrees |

|

|

|

Directivity Factor (Q) | 5.6 averaged 1kHz to 6kHz |

|

| |

Directivity Index (DI) | 7.0 averaged 1kHz to 6kHz |

|

| |

Rated Maximum SPL (2) | 106dB |

|

|

|

Average |

|

|

| |

Peak | 112dB |

|

|

|

Power Handling | 50W |

|

|

|

Average |

|

|

| |

Programme | 100W |

|

|

|

Peak | 200W |

|

|

|

Recommended Amplifier Power 100W @ 6 Ohms |

|

|

| |

Nominal Impedance | 6 Ohms |

|

|

|

Transformer Taps (via front rotary switch) |

|

|

| |

70V | 30W / 15W / 7.5W / 3.75W/ OFF |

|

| |

100V | & Low Impedance operation |

|

| |

30W / 15W / 7.5W / OFF |

|

| ||

| & Low Impedance operation |

|

| |

Distortion | 2nd Harmonic | 3rd Harmonic |

|

|

10% Full Power |

|

| ||

250Hz | 2.81% | 0.14% |

|

|

1kHz | 0.5% | 0.25% |

|

|

10kHz | 1.77% | 0.04% |

|

|

1% Full Power | 2nd Harmonic | 3rd Harmonic |

|

|

250Hz | 0.18% | 0.09% |

|

|

1kHz | 0.16% | 0.22% |

|

|

10kHz | 0.32% | 0.09% |

|

|

Crossover | 7kHz inductively coupled |

|

| |

(1) Average over stated bandwidth. Measured at 1 metre on axis.

(2) Unweighted pink noise input, measured at 1 metre in an anechoic chamber

(3) Long term power handling capacity as defined in EIA - 426B test

A full range of measurements, performance data, CLF and Ease™ Data can be downloaded from www.tannoy.com

Full independent verification of published specifications carried out by NWAA Labs, California can also be obtained from the downloads section of www.tannoy.com Tannoy operates a policy of continuous research and development. The introduction of new materials or manufacturing methods will always equal or exceed the published specifications, which Tannoy reserves the right to alter without prior notice. Please verify the latest specifications when dealing with critical applications.

|

|

|

|

|

|

|

|

| Transducers |

|

|

| Low Frequency | 130mm(5.00")mineralloaded | |||

| High Frequency | polypropylene ICT™ | |||

| ICT™ aluminium dome |

| |||

| Physical |

|

| ||

| Enclosure | Zinc plated steel | |||

| Back can | ||||

| Baffle | Reflex loaded UL | |||

| Grille | Steel, with weather resistant coating | |||

| Safety Features | Safety ring located at rear of enclosure |

| ||

| Clamping Design | for load bearing safety bond | |||

| Security toggle clamp |

| |||

| Min / Max Clamping Range | 0.0mm (0.0") / 20.0mm (0.79") | |||

| Recommended Clamp Torque | 1.5Nm | |||

| Back Can Options | Complete with fixed back can | |||

| Blind Mount (BM) | ||||

| Pre Install (PI) | Separate back can for pre installation | |||

| Cable Entry Options | Cable clamp and squeeze connector for |

| ||

| Conduit Knockouts | conduit up to 22mm | |||

| 3 Sets of horizontal positions |

| |||

| Connectors | 19 / 22 / 28mm (0.75" / 0.87" / 1.10") | |||

| Removable locking connector with screw |

| |||

|

|

|

| terminals with "loop through" facility | |

| Safety Agency Ratings (pending) |

| |||

| BM Hole Cutout Diameter | 190mm (7.48") |

| ||

| PI Hole Cutout Diameter | 190mm (7.48") |

| ||

| Dimensions | 210mm (8.27") | |||

| Bezel diameter | ||||

| Front of ceiling to | 189.5mm (7.46") | |||

| rear of back can (BM) | ||||

| Front of ceiling to | 206.8mm (8.14") | |||

| top of safety loop (BM) | ||||

| Front of ceiling surface to | 135.6mm (5.34") | |||

| rear of speaker unit (PI) | ||||

| Front of accessory back can | 153.50mm (6.04") |

| ||

| bezel to top of safety loop (PI) | ||||

| Net Weight (ea) | 3.60kg (7.94lbs) | |||

| CMS501 BM | ||||

| CMS501 PI | 2.90kg (6.39lbs) | |||

| PI back can | 2.60kg (5.73lbs) | |||

| Included Accessories | C Ring, tile bridge, paint mask, |

| ||

| Optional Accessories | cutout template, grille | |||

| Plaster (Mud) Ring |

| |||

Ordering Information

Ordering Information

|

|

|

| PART NUMBER | MODEL NAME | BAFFLE / GRILLE COLOUR | PACKED QUANTITY |

| ||

|

|

|

|

|

|

| ||||

| 8001 4450 | CMS501 BM | White / paintable | 2 |

|

|

| |||

|

|

|

| |||||||

| 8001 4460 | CMS501 PI | White / paintable | 2 |

|

|

| |||

| 8001 4180 | CMS501 Plaster (Mud) Ring | Zinc plated steel | 10 |

|

|

| |||

|

|

|

| |||||||

|

| 8001 3830 | CMS501 PI back can | Zinc plated steel | 1 |

|

|

| ||

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tannoy United Kingdom

Tannoy North America

Tannoy Deutschland

Tannoy France

T:00 44 (0) 1236 420199

T:00 1 (519) 745 1158

T:00 49 (180) 1111 881

T:00 33 (0)1 7036 7473

E:enquiries@tannoy.com

E:inquiries@tannoyna.com

E:anfragen@tannoy.com

E:ventes@tannoy.com

Tannoy adopts a policy of continuous improvement and product specification is subject to change | CMS501 data file // issue 1.06 // 10.01.08 |