Easy Calibration & Test Data Storage

An

The 9950 stores up to 99 individual tests (including a complete set of measurements and boiler ID number) which are maintained in a

Sample Integrity is Never in Question

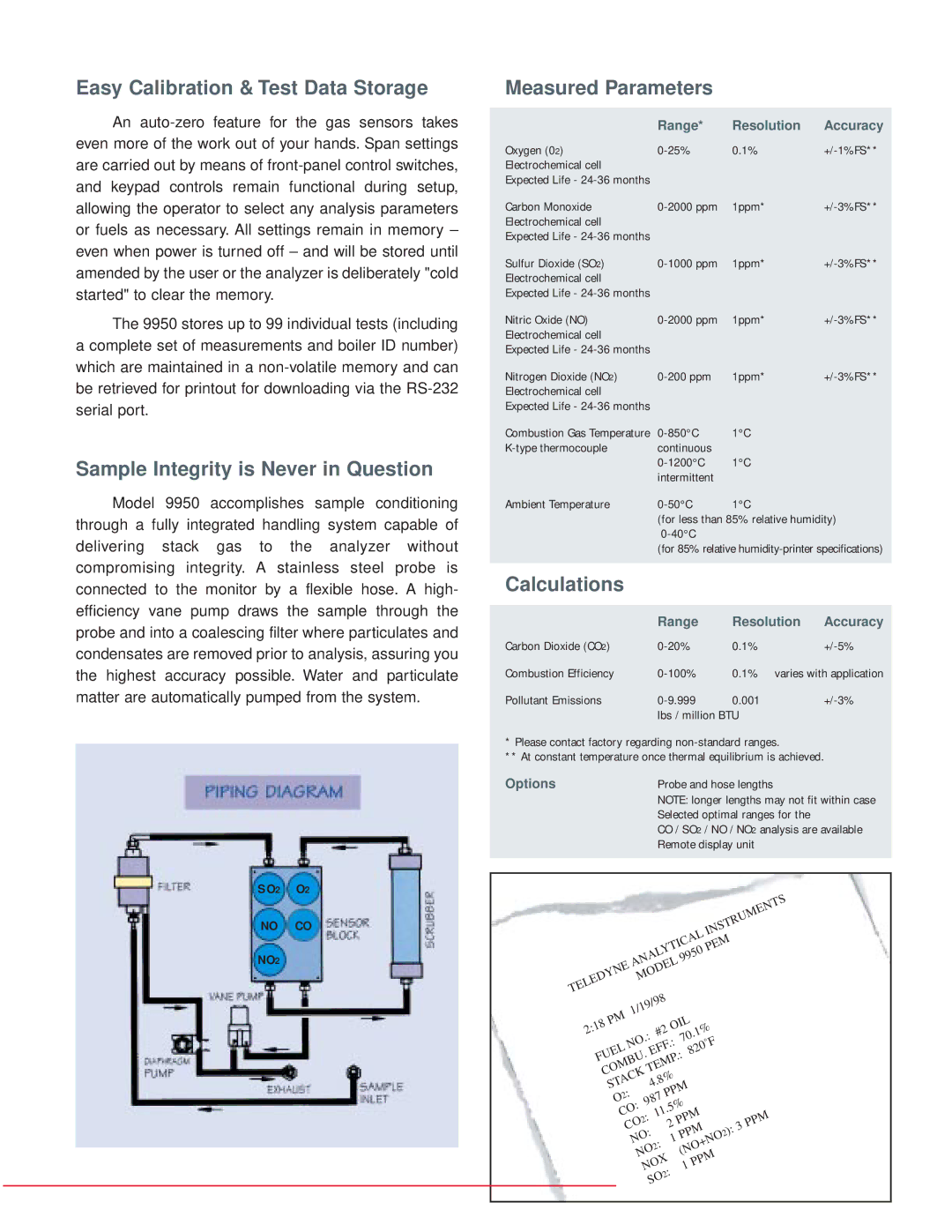

Model 9950 accomplishes sample conditioning through a fully integrated handling system capable of delivering stack gas to the analyzer without compromising integrity. A stainless steel probe is connected to the monitor by a flexible hose. A high- efficiency vane pump draws the sample through the probe and into a coalescing filter where particulates and condensates are removed prior to analysis, assuring you the highest accuracy possible. Water and particulate matter are automatically pumped from the system.

SO2 O2

NO CO

NO2

Measured Parameters

| Range* | Resolution | Accuracy |

Oxygen (02) | 0.1% | ||

Electrochemical cell |

|

|

|

Expected Life - |

|

|

|

Carbon Monoxide | 1ppm* | ||

Electrochemical cell |

|

|

|

Expected Life - |

|

|

|

Sulfur Dioxide (SO2) | 1ppm* | ||

Electrochemical cell |

|

|

|

Expected Life - |

|

|

|

Nitric Oxide (NO) | 1ppm* | ||

Electrochemical cell |

|

|

|

Expected Life - |

|

|

|

Nitrogen Dioxide (NO2) | 1ppm* | ||

Electrochemical cell |

|

|

|

Expected Life - |

|

|

|

Combustion Gas Temperature | 1°C |

| |

continuous |

|

| |

| 1°C |

| |

| intermittent |

|

|

Ambient Temperature | 1°C |

| |

| (for less than 85% relative humidity) | ||

|

|

| |

| (for 85% relative | ||

|

|

|

|

Calculations |

|

|

|

| Range | Resolution | Accuracy | |

Carbon Dioxide (CO2) | 0.1% |

| ||

Combustion Efficiency | 0.1% | varies with application | ||

Pollutant Emissions | 0.001 |

| ||

| lbs / million BTU |

|

| |

*Please contact factory regarding

**At constant temperature once thermal equilibrium is achieved.

Options |

|

|

|

|

|

|

| Probe and hose lengths | |||||||

|

|

|

|

|

|

|

| NOTE: longer lengths may not fit within case | |||||||

|

|

|

|

|

|

|

| Selected optimal ranges for the | |||||||

|

|

|

|

|

|

|

| CO / SO2 / NO / NO2 analysis are available | |||||||

|

|

|

|

|

|

|

| Remote display unit | |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| INSTRUMENTS | ||

|

|

|

|

| ANALYTICAL |

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| PEM |

| |

|

|

|

|

|

|

|

|

|

|

|

| 9950 |

|

| |

TELEDYNE | MODEL |

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

| |||||

| PM |

| 1/19/98 |

|

|

|

|

|

| ||||||

2:18 |

|

|

|

|

|

|

| OIL |

|

| |||||

|

|

|

|

| : | #2 |

|

| |||||||

|

|

|

|

|

|

|

| .1% |

|

| |||||

|

|

|

|

|

| . |

|

| .: | 70 |

|

| |||

|

|

| NO |

|

|

| 820˚F |

|

| ||||||

FUEL |

|

|

| .EFF | .: |

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

| |||||

COMBU TEMP |

|

|

|

| |||||||||||

| STACK 4 |

|

|

|

|

|

|

|

| ||||||

| 2 |

|

|

| .8% |

|

|

|

| ||||||

|

|

|

|

|

| PPM |

|

| |||||||

| O | : | 987 |

|

|

|

|

|

|

| |||||

|

|

|

|

| .5% |

|

|

| |||||||

| CO: |

|

|

| |||||||||||

|

|

|

|

|

|

| |||||||||

|

| 11 |

|

|

|

|

| 3PPM | |||||||

|

| CO |

|

| 2PPM |

| |||||||||

|

|

|

|

|

| : |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PPM | ): | ||

|

|

|

|

| NO: |

|

|

| 1 | 2 |

| ||||

|

|

|

|

| : |

| (NO+NO |

| |||||||

|

|

|

|

| NO |

|

|

|

|

| |||||

|

|

|

|

|

|

| 2 |

|

|

|

|

|

|

| |

|

|

|

|

|

| NOX |

|

| 1PPM |

|

| ||||

|

|

|

|

|

|

|

|

| : |

|

|

|

|

| |

|

|

|

|

|

|

|

| 2 |

|

|

|

|

|

| |

|

|

|

|

|

| SO |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|