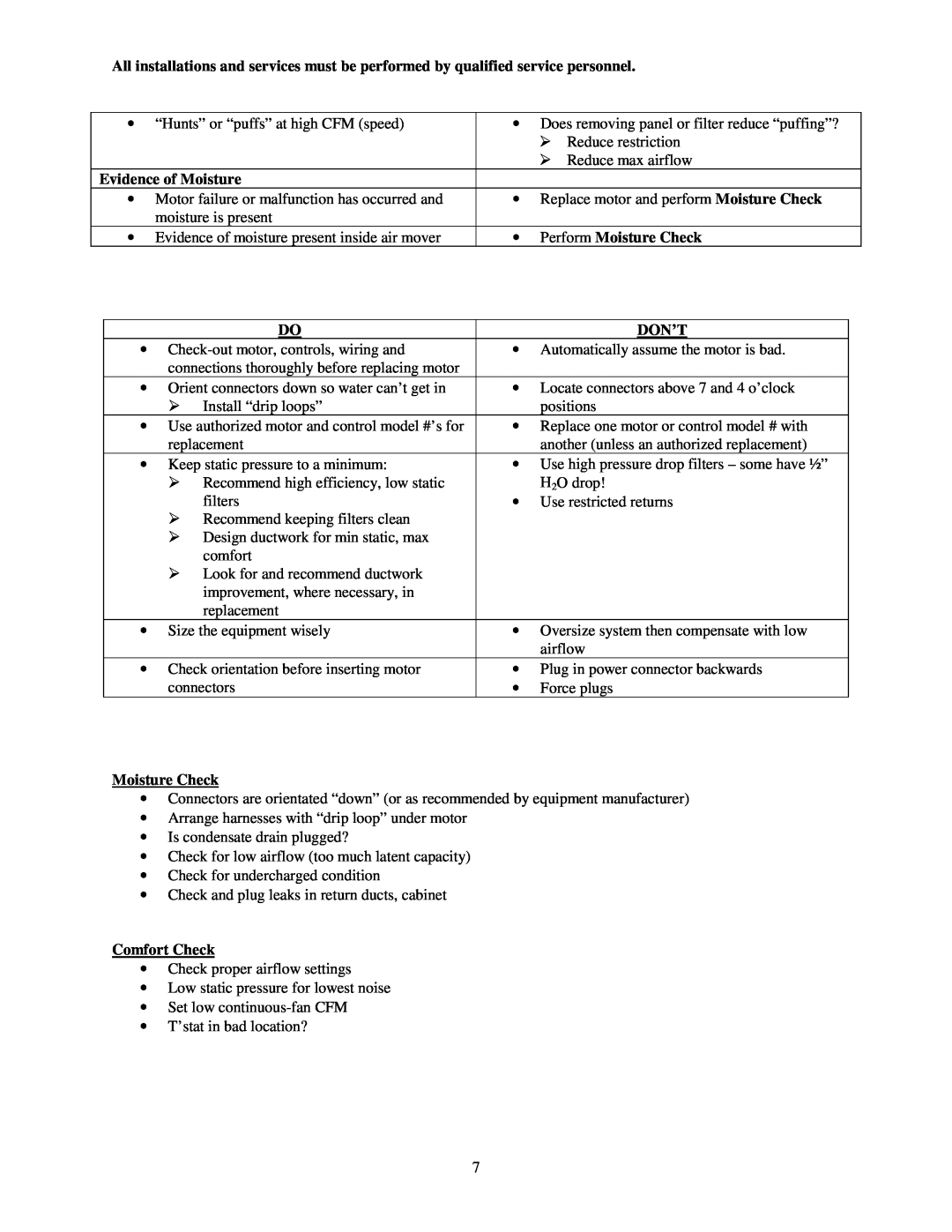

All installations and services must be performed by qualified service personnel.

• | “Hunts” or “puffs” at high CFM (speed) | • | Does removing panel or filter reduce “puffing”? | |

|

|

| ! | Reduce restriction |

|

|

| ! | Reduce max airflow |

Evidence of Moisture |

|

|

| |

• | Motor failure or malfunction has occurred and | • | Replace motor and perform Moisture Check | |

| moisture is present |

|

|

|

• | Evidence of moisture present inside air mover | • | Perform Moisture Check | |

|

| DO |

| DON’T |

• | • | Automatically assume the motor is bad. | ||

| connections thoroughly before replacing motor |

|

| |

• | Orient connectors down so water can’t get in | • | Locate connectors above 7 and 4 o’clock | |

| ! | Install “drip loops” |

| positions |

• | Use authorized motor and control model #’s for | • | Replace one motor or control model # with | |

| replacement |

| another (unless an authorized replacement) | |

• | Keep static pressure to a minimum: | • | Use high pressure drop filters – some have ½” | |

| ! Recommend high efficiency, low static |

| H2O drop! | |

|

| filters | • | Use restricted returns |

| ! | Recommend keeping filters clean |

|

|

| ! | Design ductwork for min static, max |

|

|

|

| comfort |

|

|

| ! | Look for and recommend ductwork |

|

|

|

| improvement, where necessary, in |

|

|

|

| replacement |

|

|

• | Size the equipment wisely | • | Oversize system then compensate with low | |

|

|

|

| airflow |

• | Check orientation before inserting motor | • | Plug in power connector backwards | |

| connectors | • | Force plugs | |

Moisture Check

•Connectors are orientated “down” (or as recommended by equipment manufacturer)

•Arrange harnesses with “drip loop” under motor

•Is condensate drain plugged?

•Check for low airflow (too much latent capacity)

•Check for undercharged condition

•Check and plug leaks in return ducts, cabinet

Comfort Check

•Check proper airflow settings

•Low static pressure for lowest noise

•Set low

•T’stat in bad location?

7