TOSHIBA INTERNATIONAL CORPORATION | INDEX | |

|

| |

Industrial Division / Houston Motor Plant | SHEET NO. | 1 of 3 |

|

| |

| ISSUED | 01/24/96 |

Motor Operation Procedure |

|

|

SUPERSEDES | NEW | |

|

| |

| REVISION | 0 |

|

|

|

| WRITTEN BY | I. MARQUEZ |

REFERENCE USE ONLY WHEN ISSUED BY MOTOR MKTG. | ||

| ||

|

|

|

| APPROVED BY | J. Bugbee |

| ||

|

| |

Motor Lubrication |

|

|

|

| |

Dist: Mktg. |

|

|

QC 1. SCOPE |

|

|

To give recommended guidelines for electric motor relubrication. |

| |

2.START UP

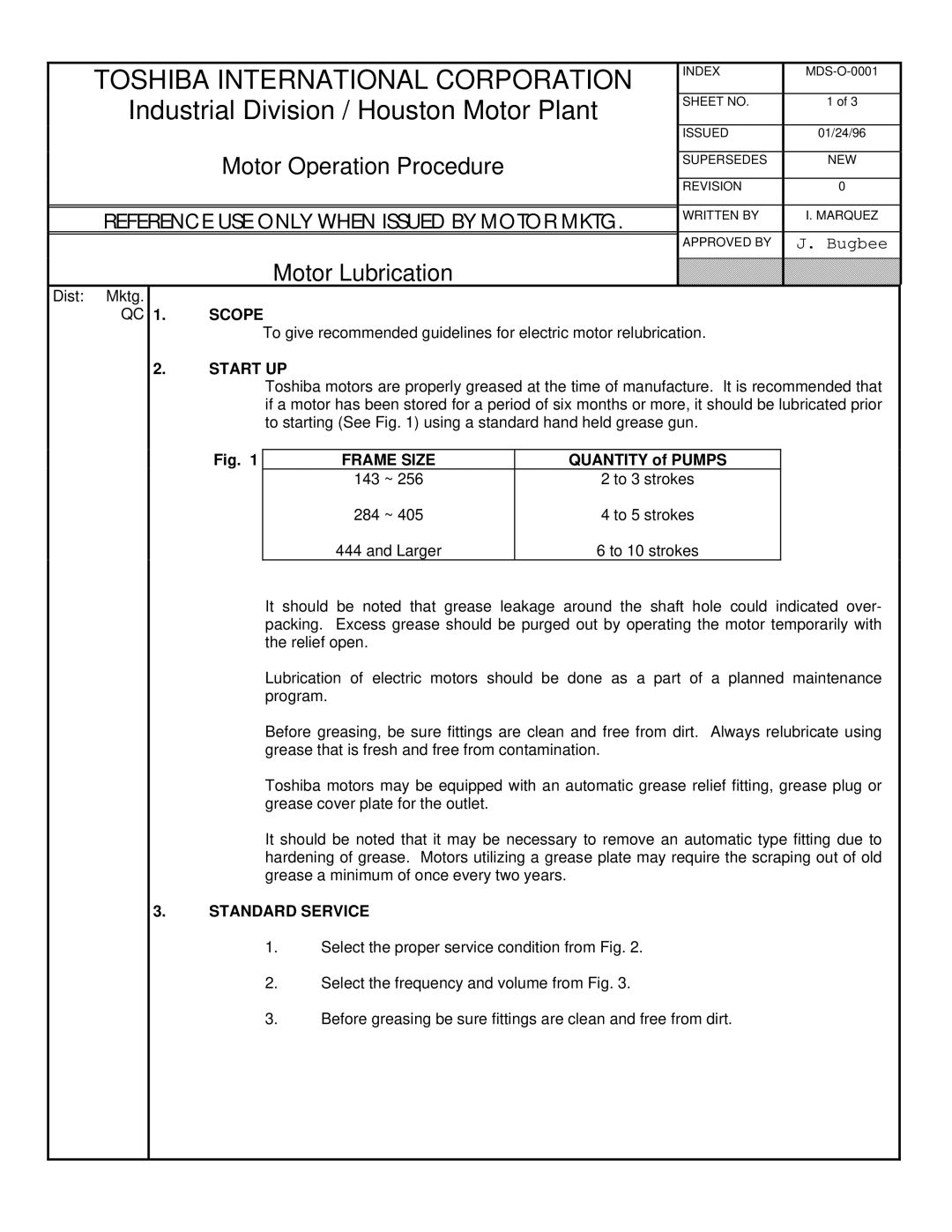

Toshiba motors are properly greased at the time of manufacture. It is recommended that if a motor has been stored for a period of six months or more, it should be lubricated prior to starting (See Fig. 1) using a standard hand held grease gun.

Fig. 1 | FRAME SIZE | QUANTITY of PUMPS |

| 143 ~ 256 | 2 to 3 strokes |

| 284 ~ 405 | 4 to 5 strokes |

| 444 and Larger | 6 to 10 strokes |

It should be noted that grease leakage around the shaft hole could indicated over- packing. Excess grease should be purged out by operating the motor temporarily with the relief open.

Lubrication of electric motors should be done as a part of a planned maintenance program.

Before greasing, be sure fittings are clean and free from dirt. Always relubricate using grease that is fresh and free from contamination.

Toshiba motors may be equipped with an automatic grease relief fitting, grease plug or grease cover plate for the outlet.

It should be noted that it may be necessary to remove an automatic type fitting due to hardening of grease. Motors utilizing a grease plate may require the scraping out of old grease a minimum of once every two years.

3.STANDARD SERVICE

1.Select the proper service condition from Fig. 2.

2.Select the frequency and volume from Fig. 3.

3.Before greasing be sure fittings are clean and free from dirt.