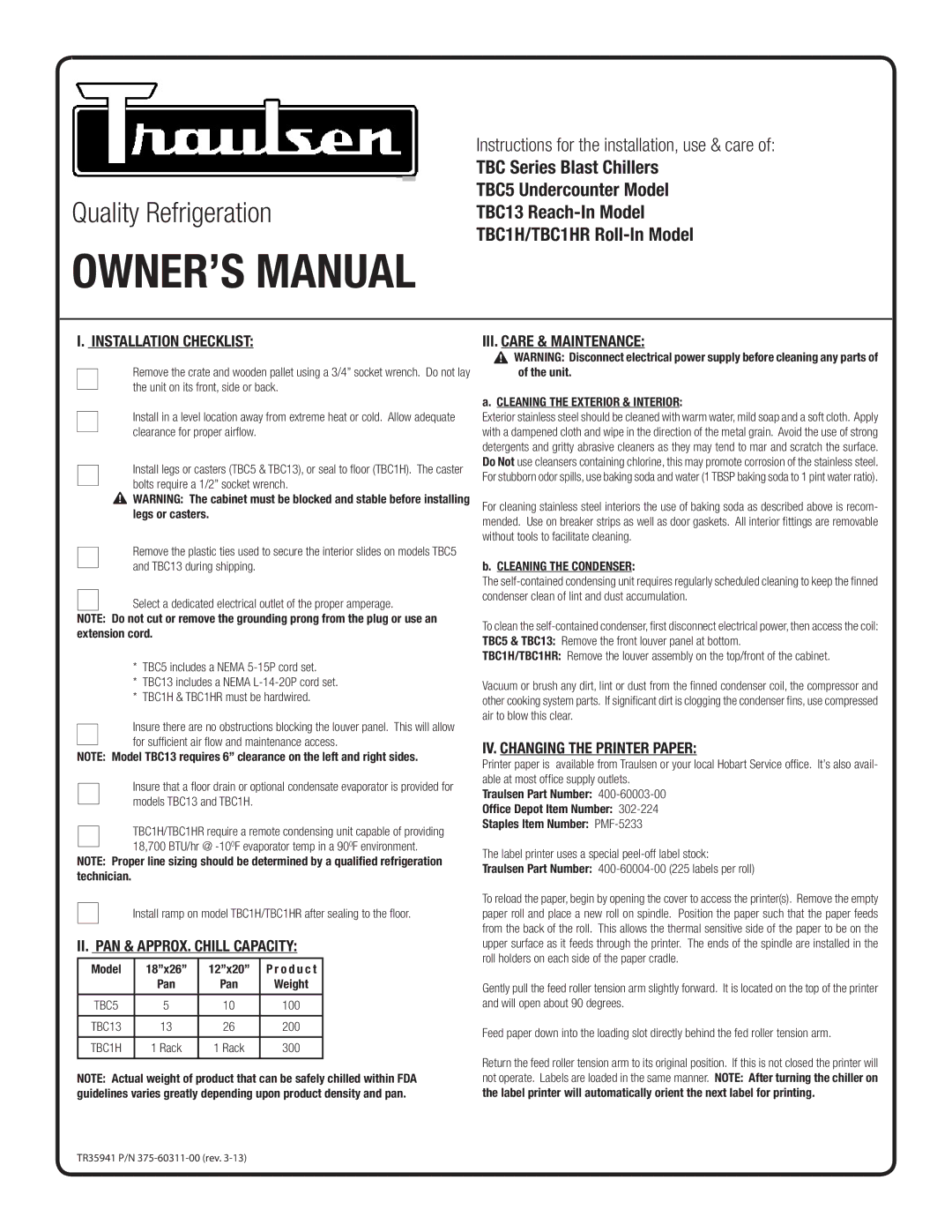

TBC5, TBC13, TBC1H, TBC1HR specifications

Traulsen is a leader in commercial refrigeration, renowned for producing high-quality products that cater to various foodservice needs. Among their popular models are the TBC1HR, TBC1H, TBC13, and TBC5 which are designed for optimal performance and reliability.The Traulsen TBC1HR is a single-section refrigerator that boasts a large capacity with a height of 79 inches. This unit is equipped with a stainless-steel exterior that not only enhances its durability but also provides an easy-to-clean surface. The TBC1HR features an advanced electronic control system, allowing for precise temperature settings and easy monitoring. Its powerful refrigeration system maintains consistent temperatures, ensuring food safety and quality.

The TBC1H is another single-section unit, noted for its versatility and space-saving design. With an efficient cooling system, it is capable of reaching temperatures as low as 33°F. This model also includes a self-closing door with a positive seal, minimizing energy loss and maximizing efficiency. The TBC1H’s interior is designed with adjustable shelves, accommodating different item sizes and configurations, making it ideal for various types of foodservice operations.

The TBC13 model stands out with its dual-temperature feature. This allows users to customize the temperature for different compartments, making it perfect for establishments that require both refrigeration and freezing capabilities in one unit. The TBC13 offers superior insulation, ensuring energy efficiency and uniform temperature distribution throughout the unit. Its robust construction includes a heavy-duty stainless-steel front and an aluminum interior, ensuring years of reliable service.

Lastly, the Traulsen TBC5 is a compact yet efficient solution for establishments with limited space. Despite its size, it delivers exceptional performance with an ample storage capacity. The TBC5 is designed with small footprint in mind, making it suitable for pizza shops, cafes, and other food service operations. It features an advanced electronic control system and LED interior lighting for enhanced visibility, along with a self-closing door to help maintain temperature and energy efficiency.

Each of these models showcases Traulsen's commitment to quality, innovation, and customer satisfaction, making them prime choices for any foodservice application. Whether it's a full restaurant kitchen or a compact deli, the TBC series provides reliable refrigeration solutions tailored to meet diverse needs.